Solventless type adhesive composition, adhesive, adhesive sheet and display body

An adhesive, solvent-free technology, applied in the direction of non-polymer organic compound adhesives, adhesive types, adhesive additives, etc., can solve problems such as air bubbles and achieve excellent anti-foaming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

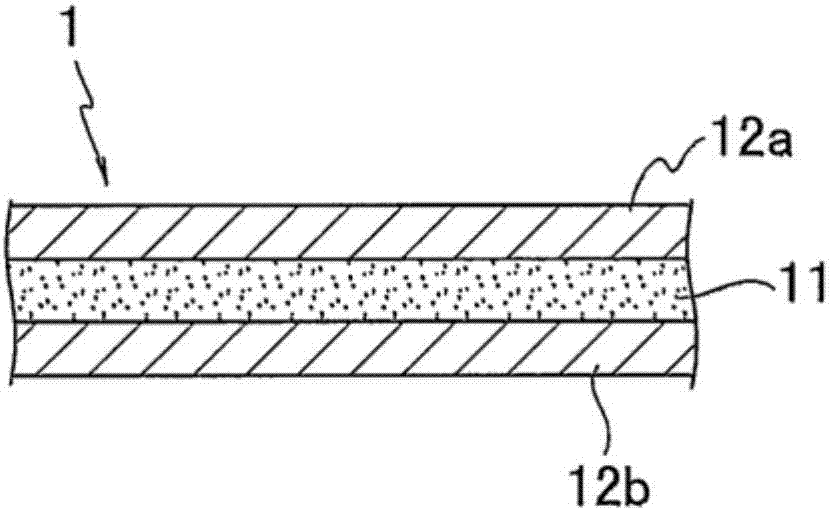

[0122] As a production example of the adhesive sheet 1, a coating layer is formed by coating the above-mentioned solvent-free adhesive composition P on the release surface of one release sheet 12a (or 12b), and another release sheet is superimposed on the coating layer. After peeling off the surface of the sheet 12b (or 12a), the coating layer is irradiated with active energy rays and / or heat-treated to form the pressure-sensitive adhesive layer 11 .

[0123] As another production example of the adhesive sheet 1, the above-mentioned solvent-free adhesive composition P is applied to the peeling surface of one release sheet 12a (or 12b), and subjected to active energy ray irradiation and / or heat treatment to make a solvent-free adhesive composition P. After the adhesive composition P is cured to form the adhesive layer 11, the release surface of the other release sheet 12b (or 12a) is superimposed on the adhesive layer 11.

[0124] As a method of applying the coating liquid of t...

Embodiment 1

[0161] 1. Preparation of solvent-free adhesive composition

[0162] 1,6-bis(trimethoxysilyl)hexane as an organoalkoxysilane was mixed with 100 parts by mass of the liquid mixture prepared in Production Example 1 above (value in terms of solid content; the same applies hereinafter). 0.3 parts by mass and 0.5 parts by mass of 1-hydroxy-cyclohexyl-phenyl-ketone as a photopolymerization initiator to obtain a solvent-free adhesive composition.

[0163] 2. Manufacture of adhesive sheet

[0164] Using a The solvent-free adhesive composition obtained in the above step 1 was applied with a knife coater.

[0165] Next, the coating layer on the heavy release type release sheet obtained above, and the light release type release sheet (LINTEC Corporation Manufactured, product name "SP-PET382120"), and bonded in such a way that the release-treated surface of the light-release type release sheet is in contact with the coating layer.

[0166] Then, the coating layer was irradiated with ul...

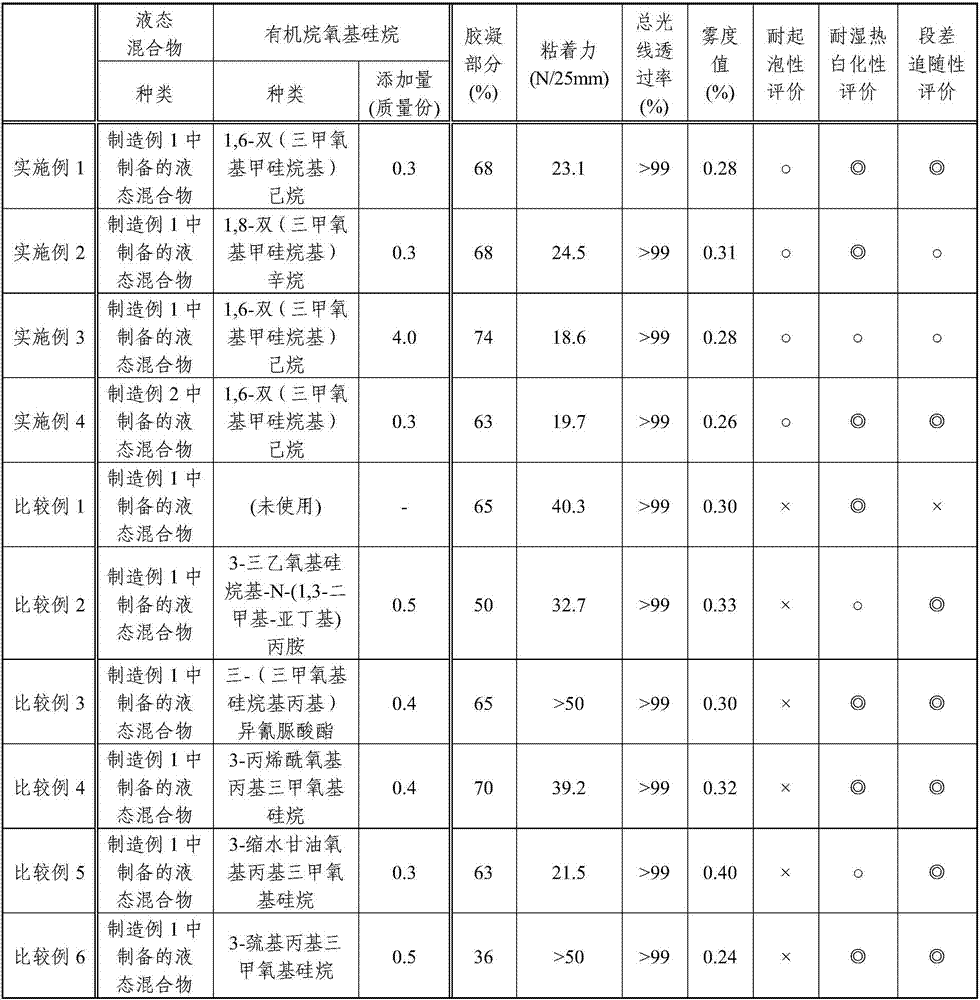

Embodiment 2~4、 comparative example 1~6

[0172] As shown in Table 1, except having changed the kind of liquid mixture, and the kind and addition amount of organoalkoxysilane, it carried out similarly to Example 1, and produced the adhesive sheet. In addition, in Comparative Example 3, tris(trimethoxysilylpropyl)isocyanurate used as an organoalkoxysilane has a so-called isocyanurate ring as the main skeleton, and relative to this main The skeleton has three trimethoxysilylpropyl groups bonded at equal intervals. Therefore, this organoalkoxysilane cannot be said to be the above-mentioned organoalkoxysilane having a linear structure, and does not correspond to the organoalkoxysilane of this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com