Transparent double-sided adhesive sheet and image display device using same

An adhesive sheet, double-sided technology, used in identification devices, adhesive types, ester copolymer adhesives, etc., can solve the blistering and peeling of component size changes, high moisture permeability, and oxidative deterioration of adhesive sheets, etc. problems, to achieve the effects of sufficient corrosion resistance reliability, improved cohesion, and excellent foam resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

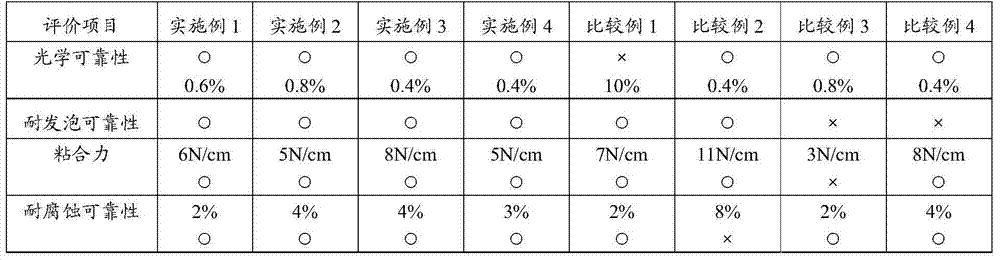

Embodiment 1

[0105] Silica particles with an average particle diameter of 12 nm (manufactured by Nippon Aerosil, trade name "AEROSIL 200V") were mixed into 1 kg of the base polymer (Tg defined by the Tan δ peak temperature of dynamic viscoelasticity: -21°C, weight average molecular weight: 400,000). ”) 30g and 4-methylbenzophenone 30g, prepared adhesive composition, described base polymer is by 70 mass parts of butyl acrylate and 30 mass parts of vinyl acetate (the Tg obtained by DSC method is 31°C) formed by random copolymerization.

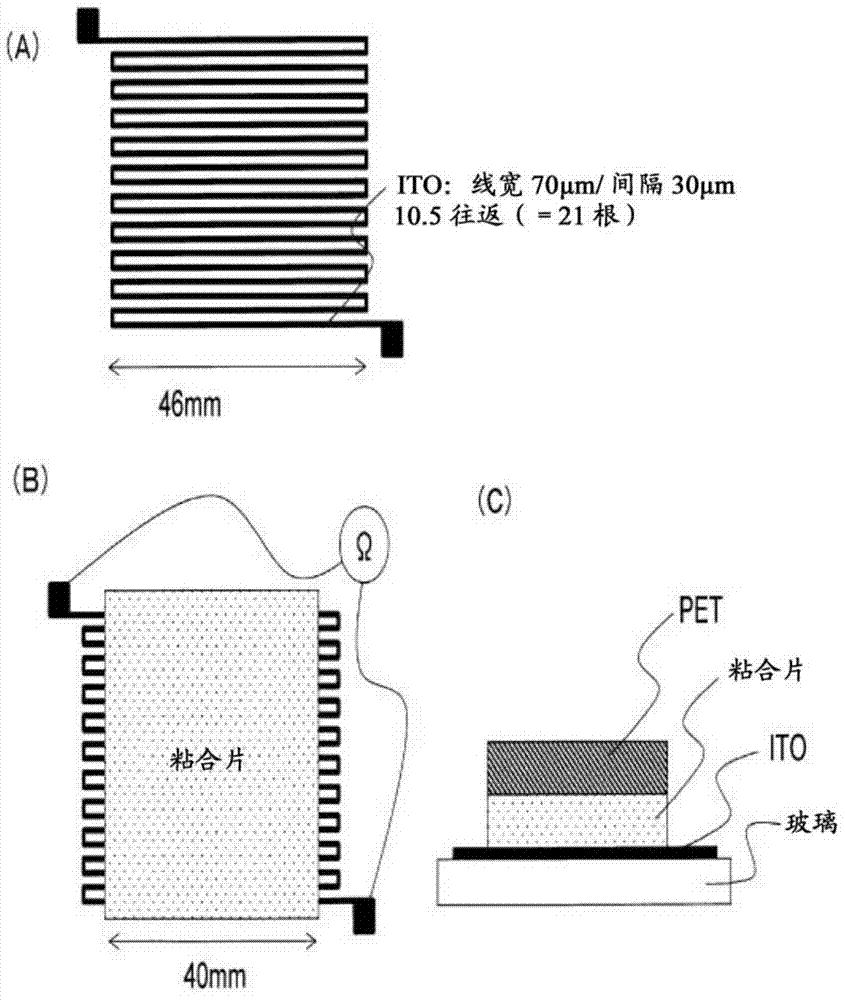

[0106] The above-mentioned adhesive composition was coated on a release PET (trade name "Diafoil MRA100") with a coater to a thickness of 150 μm, and then a release film was coated on the surface coated with the adhesive composition. Die PET (Diafoil MRF75).

[0107] Irradiate 365nm ultraviolet rays with a high-pressure mercury lamp from both surfaces sandwiching the release PET, so that the accumulated light amount reaches 1000mJ / cm 2 , and an adhesive sh...

Embodiment 2

[0109] Except that the base polymer was changed to the following acrylate copolymer (Tg defined by Tan δ peak temperature of dynamic viscoelasticity: -30°C, weight average molecular weight: 350,000), and the addition amount of silica fine particles was changed to 10g In the same manner as in Example 1, an adhesive sheet 2 was produced in which the acrylate copolymer was formed by random copolymerization of 80 parts by mass of 2-ethylhexyl acrylate and 20 parts by mass of 2-hydroxypropyl acrylate.

Embodiment 3

[0111] In addition to changing the base polymer to the following acrylate copolymer (Tg defined by the Tanδ peak temperature of dynamic viscoelasticity: -14°C, weight-average molecular weight: 420,000), and silica particles (Nippon Aerosil Company manufactures, trade name " AEROSIL 200V ") addition amount is changed to 50g, similarly to Example 1, adhesive sheet 3 is made, and described acrylate copolymer is made of butyl acrylate 69 mass parts, vinyl acetate 30 Parts by mass (Tg determined by DSC method: 31° C.) and 1 part by mass of acrylic acid were randomly copolymerized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com