EPDM composition

A composition and filler technology, applied in the field of EPDM compositions, can solve the problems of long time, poor processability, poor moldability, easy foaming, etc., and achieve excellent foaming resistance, excellent moldability, and air tightness. Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

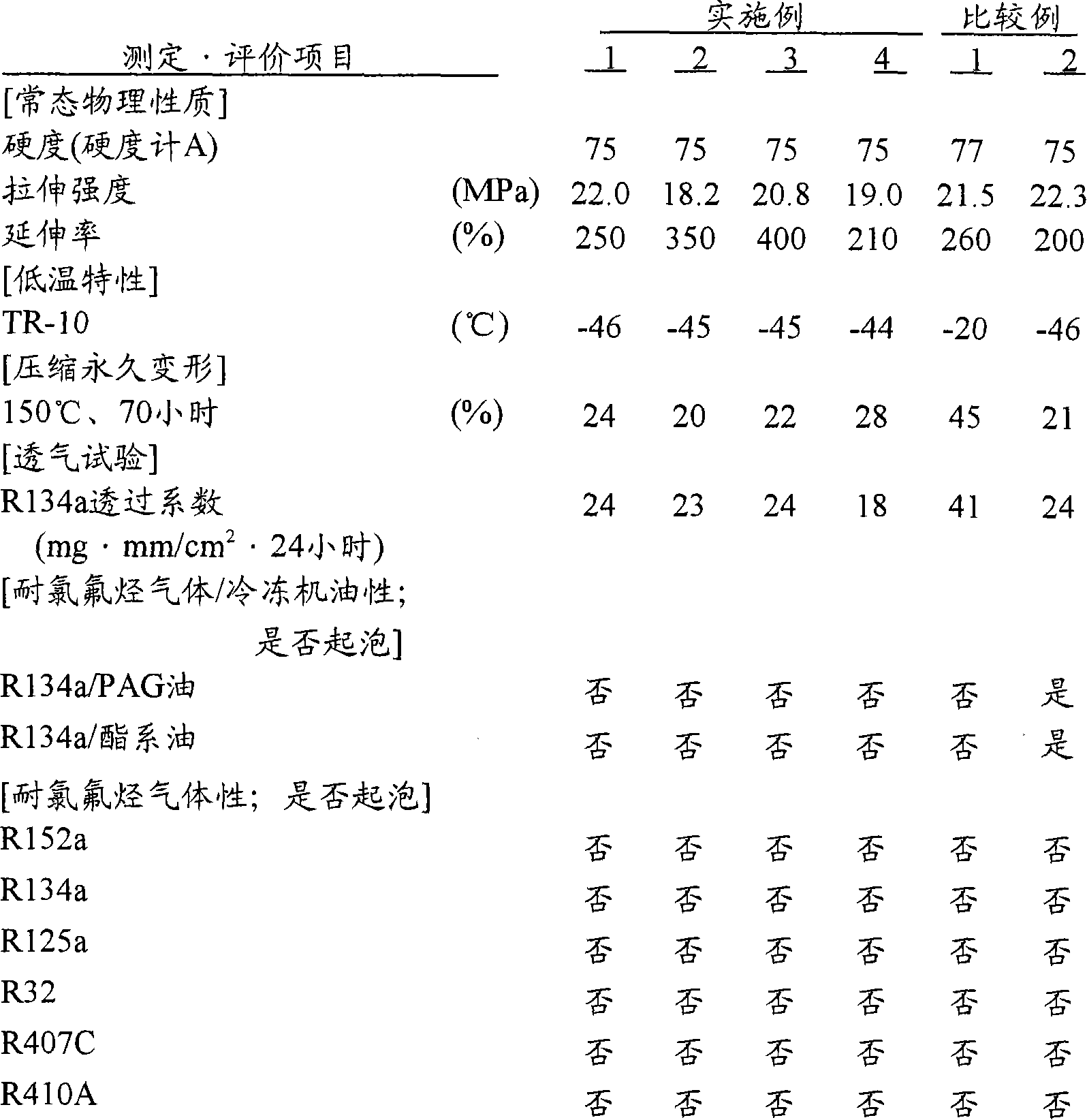

Embodiment 1

[0047] EPDM (Mitsui Chemicals EPT4045; ethylene content 54%

[0048] 100 parts by weight

[0049] Weight, Mooney Viscosity ML 1+4 (100°C)45)

[0050] SRF carbon black (average particle diameter 70nm) 70 parts by weight

[0051] Zinc oxide 5 parts by weight

[0052] 1 part by weight of anti-aging agent (Nocrack CD of Ouchi Shining Chemical Co., Ltd.)

[0053] 2.5 parts by weight of dicumyl peroxide

[0054] Use a kneader and an open roll to knead the above components. For the kneaded product, use a vulcanization press to vulcanize under pressure at 170° C. for 15 minutes and use a hot oven for secondary vulcanization at 150° C. for 5 hours to obtain vulcanized flakes (150× 150×2mm) and P-24 size O-rings.

Embodiment 2

[0056] In Example 1, the amount of SRF carbon black was changed to 25 parts by weight, and 30 parts by weight of white carbon black (specific surface area 90m 2 / g) and 2 parts by weight of vinyltrimethoxysilane.

Embodiment 3

[0058] In Example 1, the amount of SRF carbon black was changed to 50 parts by weight, and 30 parts by weight of aluminum silicate (average particle diameter: 1.4 μm) and 2 parts by weight of vinyltrimethoxysilane were further added and used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com