Al-Zn-Mg-Cu series ultrahigh-strength aluminum alloy and preparation method thereof

An ultra-high-strength, aluminum alloy technology, applied in the field of ultra-high-strength aluminum alloy materials, Al-Zn-Mg-Cu series ultra-high-strength aluminum alloys and its preparation, can solve the difficulties in preparing three-dimensional large-size materials, increase production costs, and process flow Complicated and other issues, to achieve the effect of high controllability of product components, low production cost, and obvious strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

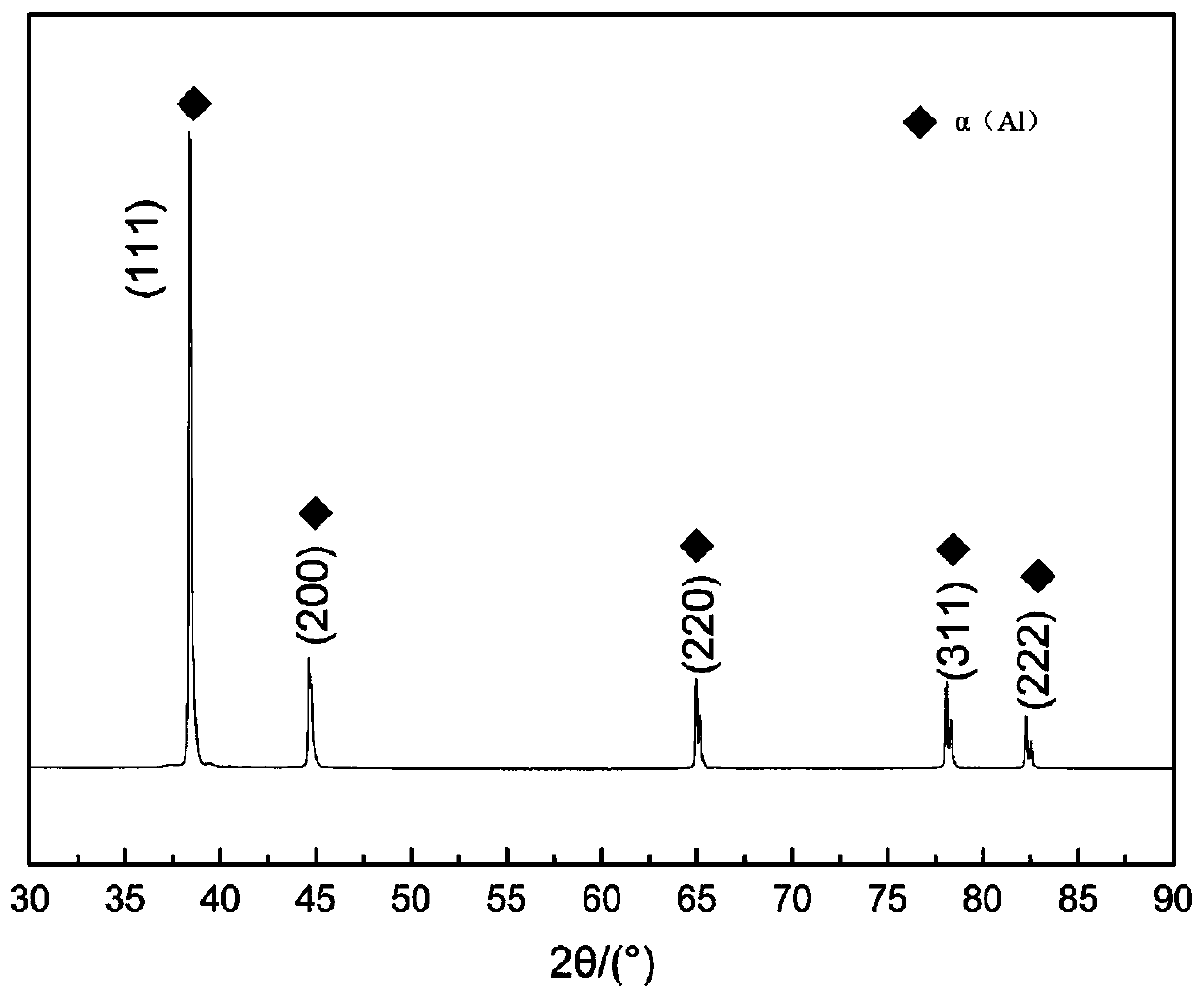

[0034] An Al-Zn-Mg-Cu series ultra-high-strength aluminum alloy has the following specific components in terms of mass percentage: 10.72% Zn, 2.43% Mg, 0.86% Cu, and the balance is Al.

[0035] (1) Heating industrial pure aluminum (purity ≥ 99.7%) to 750°C to 800°C in a crucible resistance furnace;

[0036] (2) After the industrial pure aluminum is completely melted, stir and let stand for 5 minutes, then add copper (purity 99.9% to 99.95%), industrial pure zinc (purity ≥ 99.7%) and industrial pure magnesium (purity ≥ 99.7%) in sequence ; During the addition process, until the previous raw material is completely melted, stir and let it stand for 5-10 minutes, then add the next raw material until all the raw materials are completely melted;

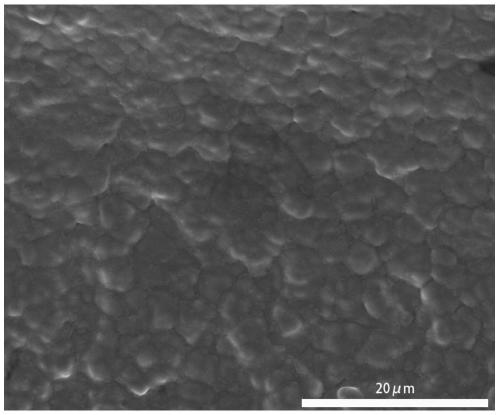

[0037] (3) When the temperature of the molten metal drops to 710°C-720°C, it is sprayed onto a high-speed rotating copper roller to obtain a strip with a rapid solidification structure, the width of the strip is 2.9-3.3mm, and the thicknes...

Embodiment 2

[0045] The main steps of this embodiment are the same as those in Embodiment 1, and the similarities will not be described in detail. The difference is that:

[0046] Utilize the cold-pressed billet prepared in embodiment 1, adopt the method for hot positive extrusion, obtain the solid bar that diameter is 8mm, concrete preparation method is as follows:

[0047] (1) First put the cold-pressed billet prepared in Example 1 into a box-type resistance furnace for heating and heat preservation, the heating temperature is 420° C., and the heat preservation time is 0.5 h; the extrusion nozzle is put into a box-type resistance furnace for heating and heat preservation, and the The temperature is 400°C, and the holding time is more than 0.5h; the extrusion mold is heated and held at 400°C, and the holding time is more than 2h;

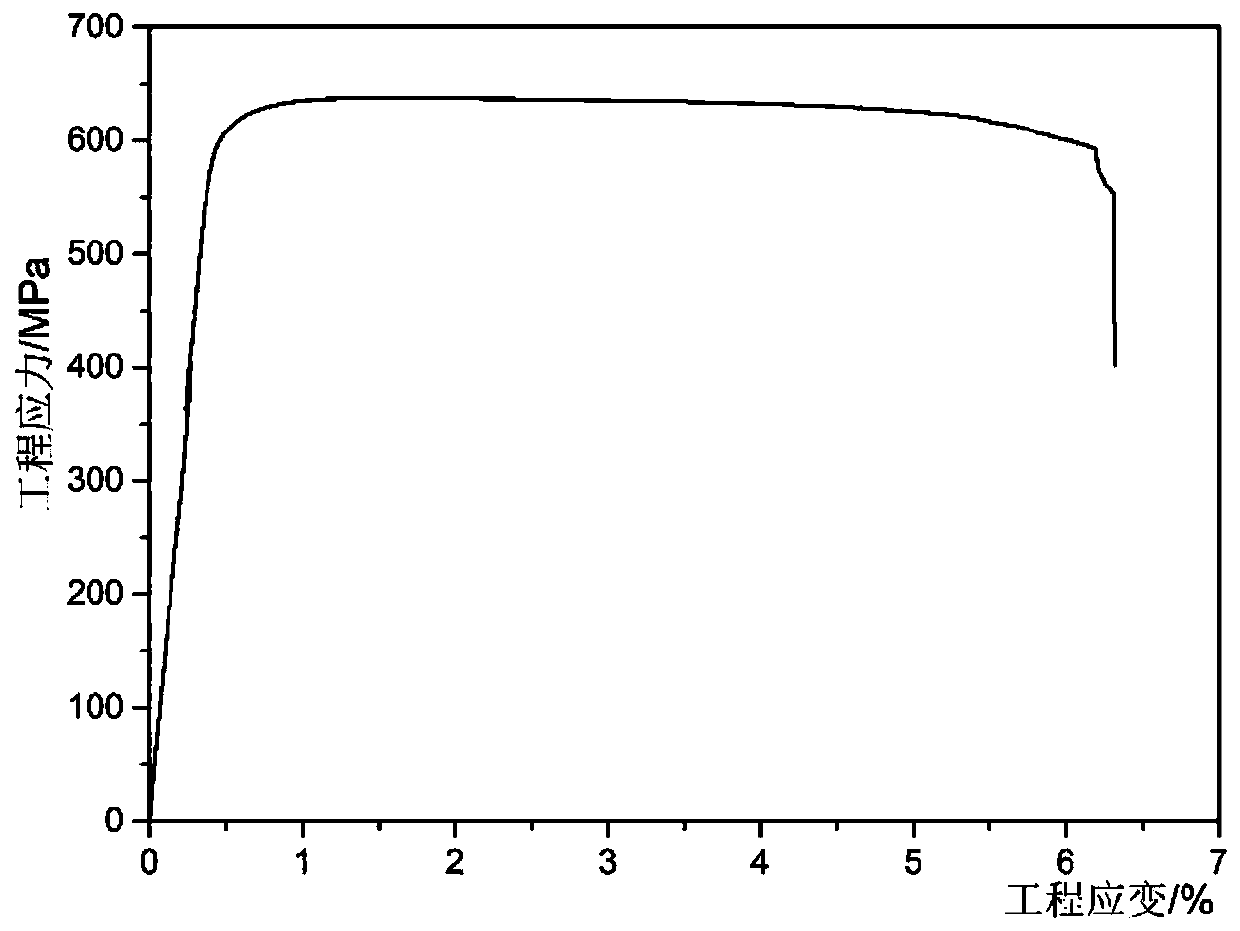

[0048] (2) After the heat preservation is completed, hot extrusion is carried out, the extrusion ratio is 39.1, and the cooling method is water quenching; then...

Embodiment 3

[0051] The main steps of this example are the same as those of Example 1, and the similarities will not be described again. The difference is that the cold-pressed billet prepared in Example 1 is used to obtain a solid rod with a diameter of 8 mm by using the method of hot forward extrusion. material, the specific preparation method is as follows:

[0052] (1) First put the cold-pressed billet prepared in Example 1 into a box-type resistance furnace for heating and heat preservation, the heating temperature is 420° C., and the heat preservation time is 0.5 h; the extrusion nozzle is put into a box-type resistance furnace for heating and heat preservation, and the The temperature is 400°C, and the holding time is more than 0.5h; the extrusion mold is heated and held at 400°C, and the holding time is more than 2h;

[0053] (2) After the heat preservation is completed, hot extrusion is carried out, the extrusion ratio is 39.1, and the cooling method is water quenching; then the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com