Ultra-high-strength zinc-aluminum-magnesium-coated steel sheet for high-temperature forming and manufacturing method thereof

A technology for forming and coating steel sheets at high temperature, applied in coating, hot-dip coating process, metal material coating process, etc., can solve the problems of high corrosion resistance, coating composition and process limitations, low productivity, etc., and achieve anti-corrosion Excellent corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

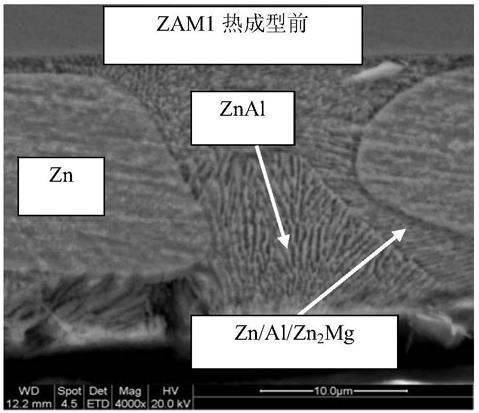

[0038] An ultra-high-strength zinc-aluminum-magnesium-coated steel sheet for high-temperature forming, its composition and weight percentage are: C: 0.25%, Si: 0.25%, Mn: 2.35%, Cr: 0.4%, B: 0.0024%, Ti: 0.037% , Nb: 0.025%, Al: 0.06%, N: 0.0028%, and the rest are Fe and unavoidable impurities. The chemical composition weight percent of the plating solution is: Al: 2.4%, Mg: 1.3%, and the rest are Zn and unavoidable impurities.

[0039] The production steps of coated steel plate are as follows:

[0040] 1) Smelting and continuous casting into billets according to the chemical composition;

[0041] 2) Hot continuous rolling controls the final rolling temperature to 880°C, the total reduction rate to 90%, and the coiling temperature to 710°C;

[0042] 3) The total reduction rate of cold rolling control is 65%;

[0043] 4) Heat the steel strip in the dew point range of -30°C to 820°C, in H 2 In a reducing atmosphere with a volume percentage of 30%, cool to 495°C at a cooling ...

Embodiment 2

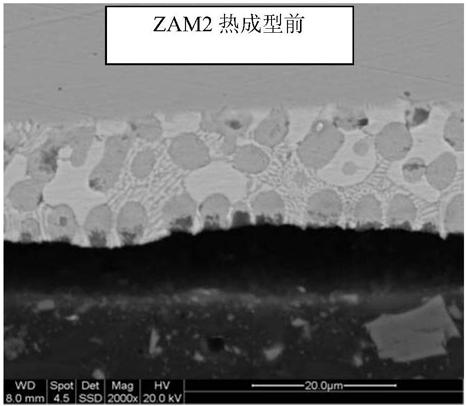

[0047] An ultra-high-strength zinc-aluminum-magnesium-coated steel sheet for high-temperature forming, its composition and weight percentage are: C: 0.35%, Si: 0.25%, Mn: 2.35%, Cr: 0.4%, B: 0.0041%, Ti: 0.045% , Nb: 0.034%, Al: 0.034%, N: 0.0035%, and the rest are Fe and unavoidable impurities. The chemical composition weight percent of the plating solution is: Al: 7.1%, Mg: 1.6%, and the rest are Zn and unavoidable impurities.

[0048] The production steps of coated steel plate are as follows:

[0049] 1) Smelting and continuous casting into billets according to the chemical composition;

[0050] 2) Hot continuous rolling controls the final rolling temperature to 800°C, the total reduction rate to 80%, and the coiling temperature to 700°C;

[0051] 3) The total reduction ratio of cold rolling control is 55%;

[0052] 4) Heat the steel strip in the dew point range of 10°C to 780°C, H 2 The volume percentage is 20%, cooled to 475°C at a cooling rate of 30°C / s, holding time...

Embodiment 3

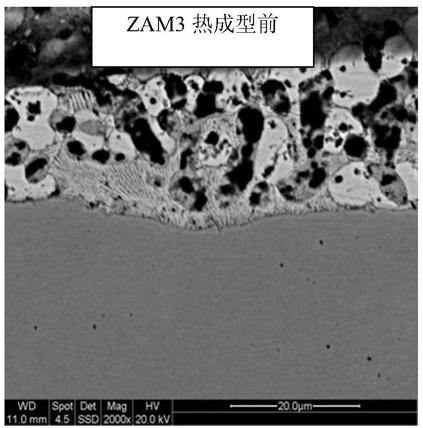

[0056] An ultra-high-strength zinc-aluminum-magnesium-coated steel sheet for high-temperature forming, its composition and weight percentage are: C: 0.53%, Si: 0.35%, Mn: 2.8%, Cr: 0.4%, B: 0.0055%, Ti: 0.063% , V: 0.1%, Al: 0.051%, N: 0.0049%, the remainder is Fe and unavoidable impurities. The chemical composition weight percent of the plating solution is: Al: 15.3%, Mg: 3.7%, and the rest are Zn and unavoidable impurities.

[0057] The production steps are as follows:

[0058] 1) Smelting and continuous casting into billets according to the chemical composition;

[0059] 2) Hot continuous rolling controls the final rolling temperature to 840°C, the total reduction rate to 95%, and the coiling temperature to 730°C;

[0060] 3) The total reduction ratio of cold rolling control is 75%;

[0061] 4) Heat the steel strip in the dew point range of 30°C to 840°C, H 2 The volume percentage is 10%, cooled to 465°C at a cooling rate of 15°C / s, holding time for 90s, then immersed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com