Rainwater pipeline structure and construction method thereof

A construction method and technology of rainwater pipes, which are applied to sewer systems, waterway systems, water supply devices, etc., can solve the problems of poor sealing of rainwater pipe joints, poor sealing of rainwater pipes, and increased construction costs, so as to ensure easy construction quality and improve sealing Sexuality and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

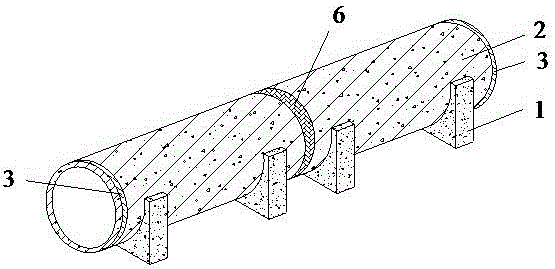

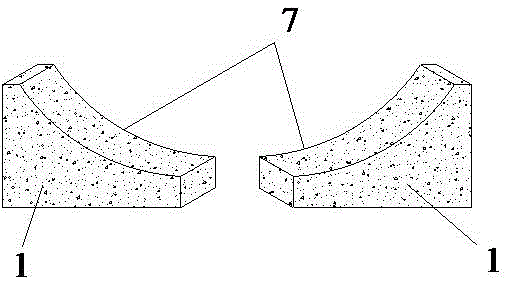

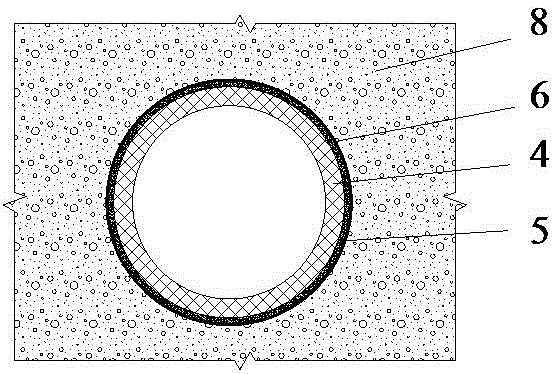

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. While the invention will be described in conjunction with the preferred embodiments, it will be understood that it is not intended to limit the invention to the described embodiments. On the contrary, the invention is to cover alternatives, modifications and equivalents, which may be included within the scope of the invention as defined by the appended claims.

[0032] The prefabrication and transportation of rainwater pipes, the binding of steel bars, the factory prefabrication of supports, the hoisting of rainwater pipes and supports, etc. will not be repeated in this embodiment, and the embodiments of the structures involved in the present invention will be focused on.

[0033] In this example, the outer diameter of the rainwater pipe is 1200mm, the length is 2000mm, and the reinforced concrete structure is adopted. The concrete type is C25. The prefab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com