Pile-splicing construction method and pile-splicing component for guiderails in expressway rebuilding and expansion and major maintenance projects

A technology for highways and construction methods, applied in infrastructure engineering, roads, roads, etc., can solve the problem of inability to guarantee vehicle traffic safety and traffic safety facility technical specifications and national standards, the relative height reduction of guardrails and road surfaces, and traffic flow safety Hidden dangers and other problems, to achieve the effect of saving transportation and reverse transportation costs, shortening transportation time, and closing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

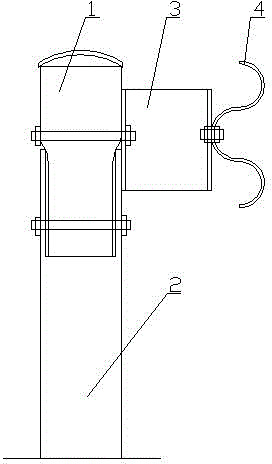

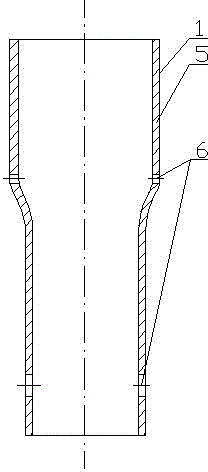

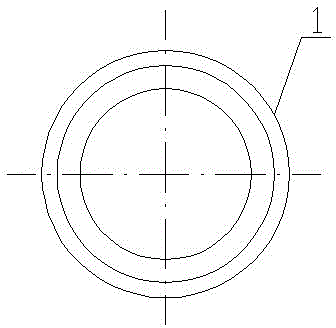

[0016] A construction method for guardrail pile connection in expressway reconstruction, expansion and overhaul projects, the method comprising the following steps: according to the diameter size of the original highway guardrail column, processing a steel pipe with a strength not lower than the original highway column strength to form a joint with variable section diameter. Pile component 1, using variable cross-section steel pipes as connectors, after the piles are connected, use a hydraulic pile driver to carry out pressure pile sinking according to the design construction size, and control the elevation and verticality during the pile sinking process through a level gauge and a verticality tester. Until the design requirements are met; through the bolt holes of the pile-connecting member and the original column 2, they are fixed and locked with high-strength bolts, so that the original column and the pile-connecting part are integrated to achieve the designed force strength;...

Embodiment 2

[0018] In the above-mentioned expressway reconstruction and expansion and overhaul project guardrail pile connection construction method, the diameter and wall thickness of the pile connection member are determined. The original material as the pile connection material should be the same as the original column material or slightly higher, and its thickness and diameter Try to be equal or not lower than that to ensure its strength and aesthetics; the determination of the length of the original material of the pile-connecting member is to ensure that the original column hole can be used to connect, and to meet the steel guardrail acceptance after the guardrail board is suspended. Standard, the length of the original material should be ≥ the increased height of the road surface + the downward pressure stroke of the pile + the hole distance of the original column + the edge length of the hole distance; after the standard size is determined, the corresponding steel pipe length is int...

Embodiment 3

[0020] In the above-mentioned construction method of highway reconstruction and expansion and overhaul project guardrail pile connection, the pile position plane layout of the pile sinking is revised, the theodolite is used for linear stakeout calibration, the level controls the elevation, and the verticality tester controls the verticality of the pile connection , the meter ruler controls the pile position spacing, and the offset value is calibrated at the original pile position so as to control the pile sinking process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com