Cast-in-place pile with positioning device combined steel formwork and its construction method

A technology of positioning device and construction method, which is applied in the direction of sheet pile wall, foundation structure engineering, building, etc., can solve problems such as spacing deviation, achieve the effects of controllable elevation and axis deviation, accurate positioning, and reduce mold swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

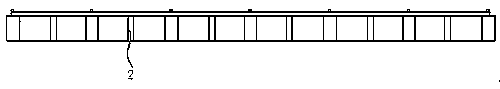

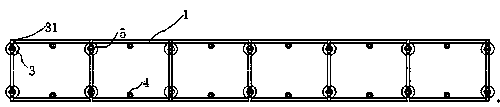

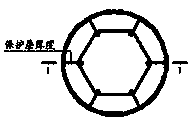

[0024] The invention firstly discloses a cast-in-place pile with a positioning device combined with a steel formwork, which includes a pile foundation positioning device and a steel formwork 3 connected to the positioning device. The cast-in-place pile is formed by pouring concrete into the steel formwork and vibrating it. The positioning device includes: a positioning bracket 1, the positioning bracket includes a frame, and a template positioning hole 31 is opened on the frame; an adjustment screw 2, one end of the adjustment screw 2 is fixed on the ground, and the other end is connected to the frame; The wire sleeve 4 is fixed on the positioning bracket 1, and the adjustment wire sleeve 4 is provided with an internal thread matched with the external thread on the adjustment screw 2. After adjusting the lead screw and the adjustment wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com