Construction method for barrel wall of prestressed concrete wind power tower and special construction equipment

A technology of a wind power tower and a construction method, which is applied to wind power generation, the configuration of installing/supporting wind turbines, cranes, etc., can solve the problems of high cost of hydraulic devices and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

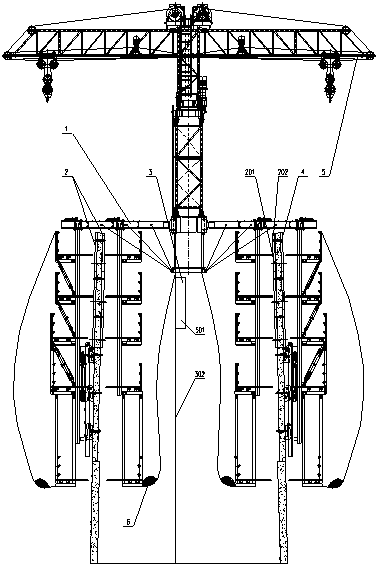

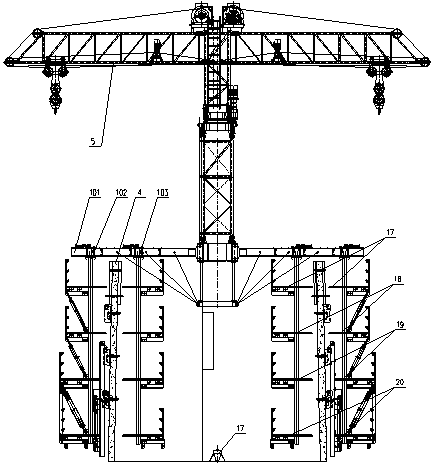

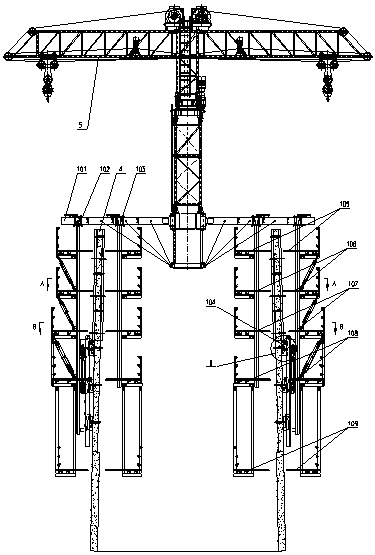

[0041] Such as figure 1 , 2 As shown, the bottom foundation of the wind power tower with a height of 4m is poured in advance, and 10 climbing cones 1047 are evenly distributed in a ring at a height of 2.8m before pouring the concrete and fixedly connected with the steel bars. After the strength of the concrete to be poured reaches 10MPa , installation pin I1041, pre-embedded pendant 1042, embedded part plate 1043, high-strength screw 1044, backing plate 1048, compression spring I1049 and nuts and gaskets of corresponding specifications to form 10 sets of wall-attached devices 104 (see Image 6 , 17 ), through the load-bearing pin 8, connect 10 sets of uprights of the overturning lifting platform with 10 sets of wall-attached devices, and use the fixed plate I1045 and fixed plate II1046 to connect the wall-attached device 104 with the upright column 1021; use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com