Autoclaved aerated block lintel and construction method thereof

A technology of autoclaved aeration and construction method, applied in joists, girders, trusses and other directions, can solve the problems of low strength and elastic modulus, large dimensional deviation, troublesome operation, etc., and achieve strong integrity, enhanced strength, Sturdy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

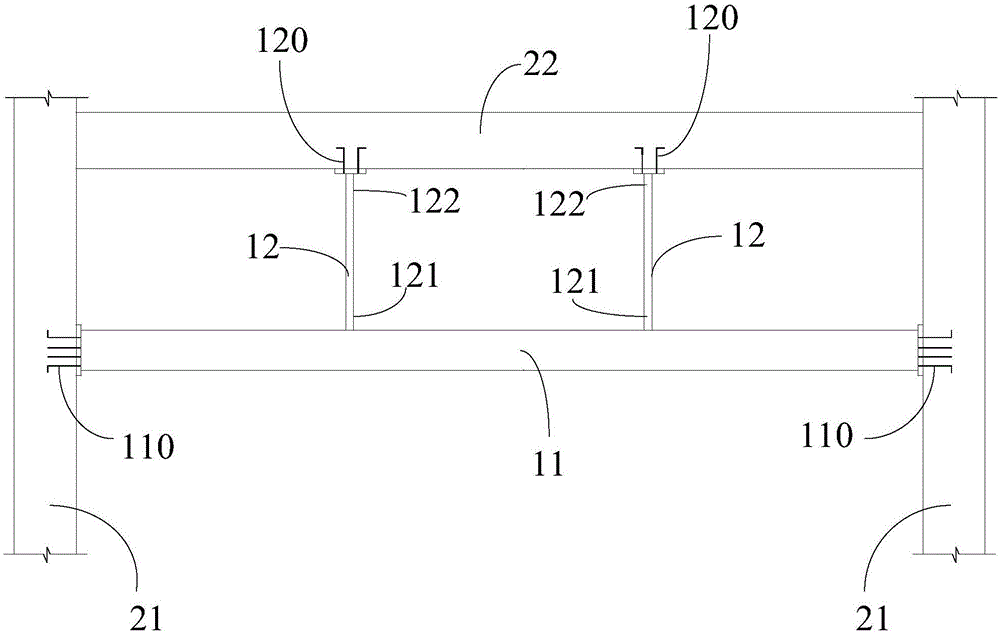

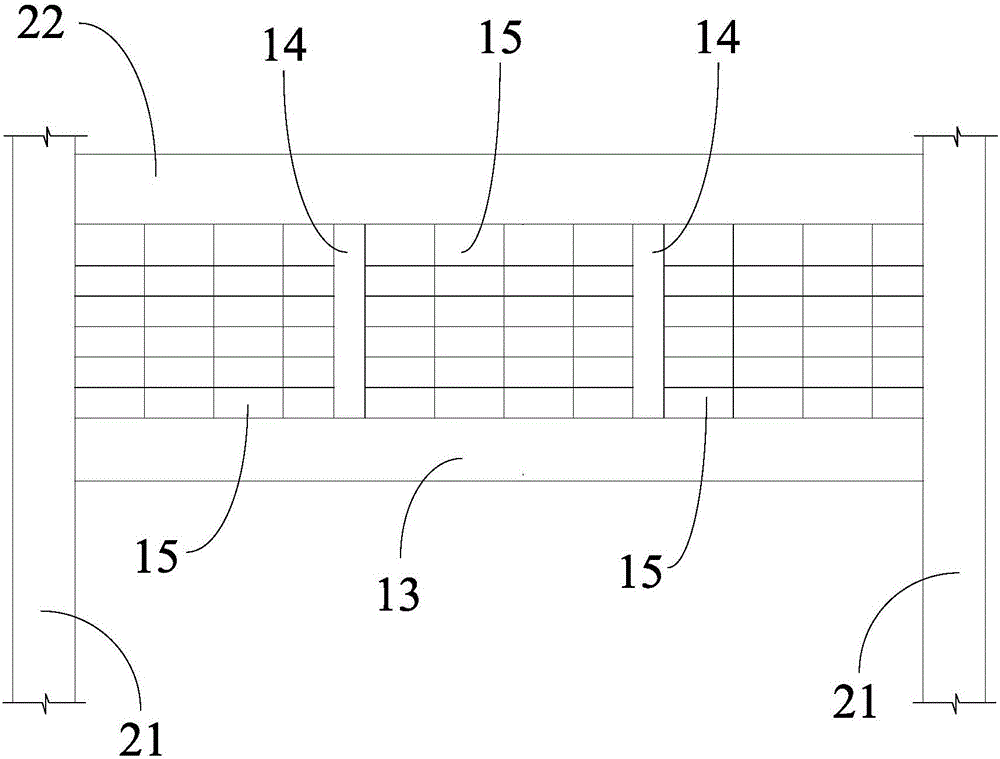

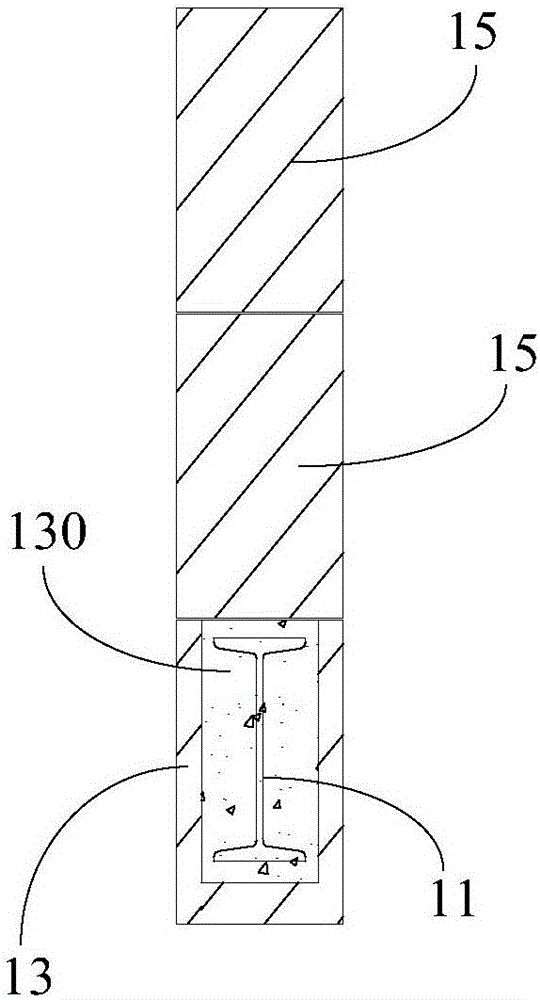

[0035] The autoclaved aerated block lintel and its construction method of the present invention are suitable for the construction of the large-span opening lintel of the autoclaved aerated block, and are comparable to the construction of the traditional cast-in-place concrete lintel and the traditional autoclaved aerated block filling wall. It has the advantages of convenient construction, high strength, high stability, and small dimensional deviation. It can also save the support of the lintel formwork and improve the quality of the wall.

[0036] The construction of the large-span opening lintel at the outer wall is taken as an example below, and a kind of autoclaved aerated block lintel and its construction method of the present invention are described in detail.

[0037] see first figure 1 and figure 2 shown, where figure 1 It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com