High-speed railway subgrade structure for saline soil areas

A high-speed railway and saline soil technology, applied to roads, road bottom layers, tracks, etc., can solve the problems of difficulty in construction control of asphalt sand barriers, inability to meet water seepage soil barriers, and large construction volume, and achieve construction quality Easy to guarantee, strong promotion and application value, and the effect of solving technical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

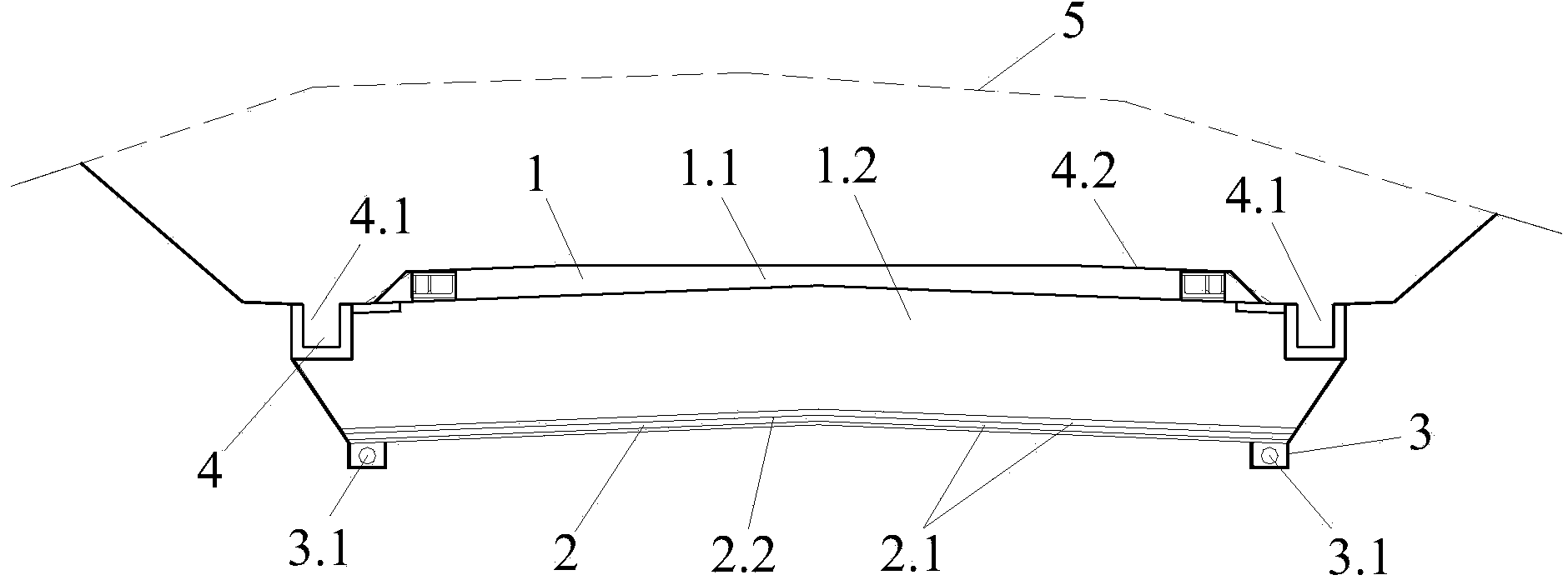

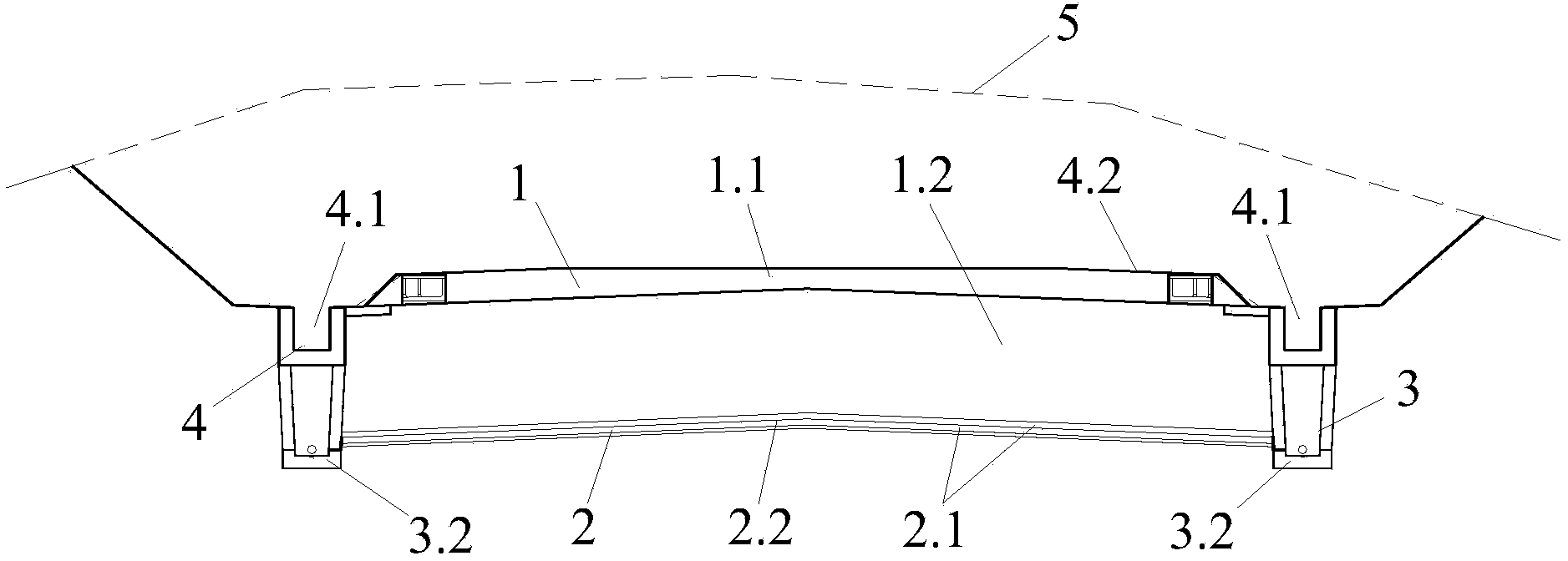

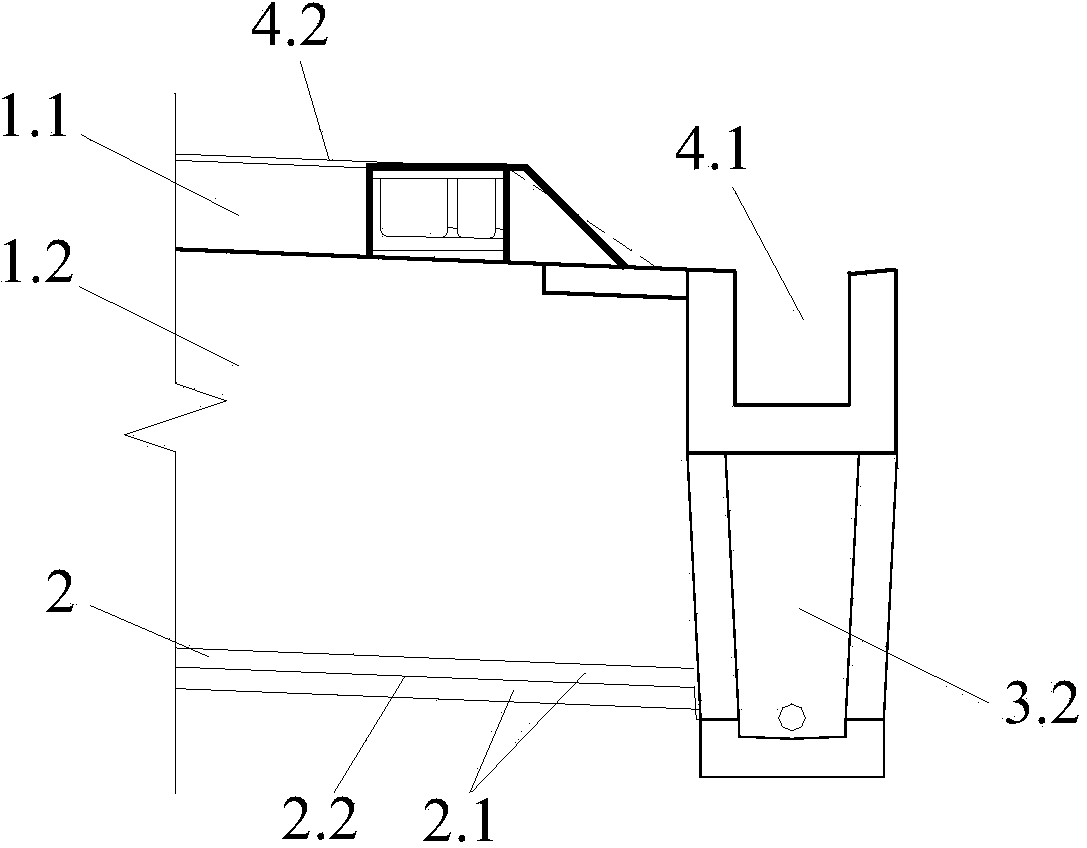

[0026] Such as Figure 1-3 As shown, the subgrade structure of the present invention is suitable for the lower terrain in the saline soil area, that is, after the subgrade structure is repaired, its top surface is lower than the original ground line 5, so it is mainly composed of cutting structure 1, partition layer 2, underground drainage System 3 and surface drainage system 4 are composed. Drainage side ditches 4.1 are arranged on both sides of the cutting structure 1, the permeable ditch 3.1 or blind drainage ditch 3.2 of the underground drainage system 3 are arranged at the lower part of the side ditch 4.1 on both sides, and the partition layer 2 is arranged at the bottom of the bottom layer 1.2 of the cutting structure bed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com