Method for detecting leaking point position of buried pipeline by gas

A buried pipeline, gas detection technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of gas leakage, unable to detect the location of water leakage points, etc., to reduce the time for leak detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A method of using gas to detect the location of a leak point of a buried pipeline, comprising the following steps:

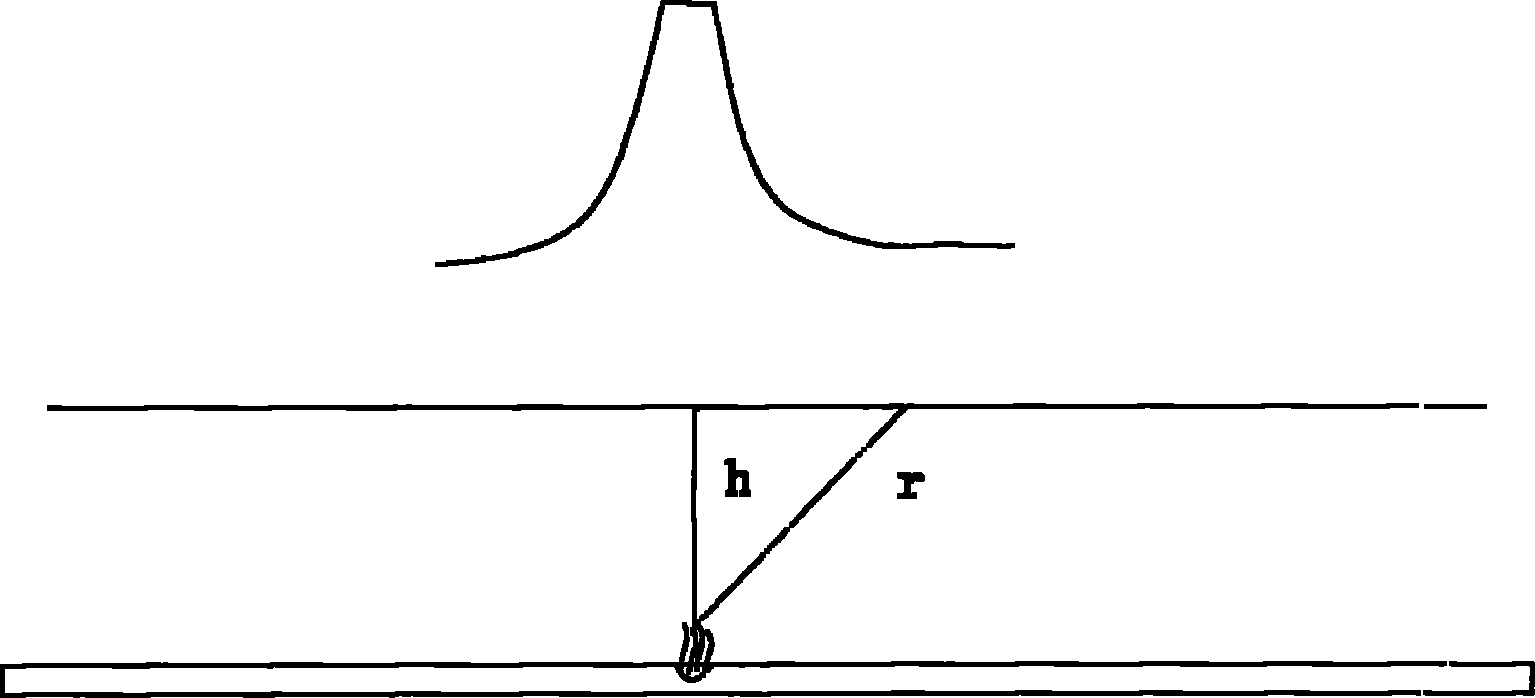

[0033] first step, such as image 3 As shown, the tracer gas E is injected into the buried pipeline F, so that the tracer gas E is distributed in the buried pipeline F, and the pressure inside the buried pipeline F is higher than atmospheric pressure.

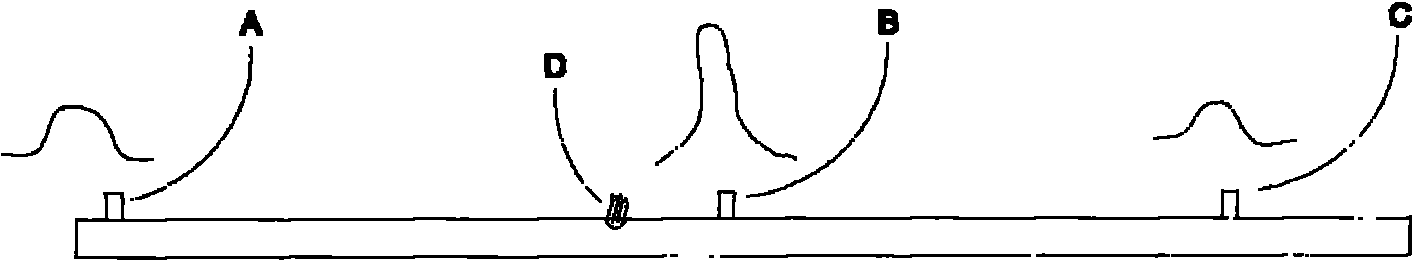

[0034] In the second step, several equidistant detection holes H are opened on the ground directly above the buried pipeline F, and gas detectors matching the tracer gas E are placed in the several detection holes H.

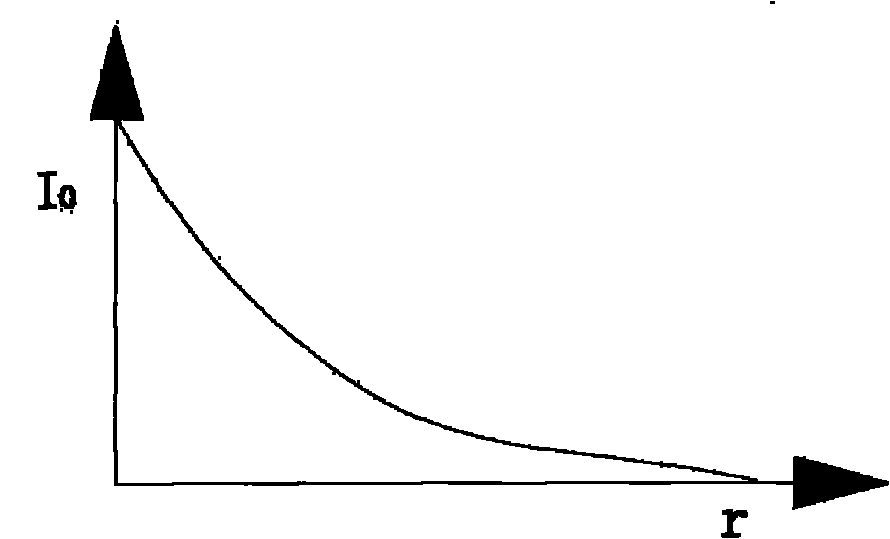

[0035] If there is a leak point G in the buried pipeline F, the tracer gas E leaks out of the buried pipeline F and penetrates directly above the buried pipeline F. At this time, the gas located above the leak point G The detector detects the tracer gas leaked from the buried pipeline F, thereby determining the position of the leak point G; if the gas detector located above the buried pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com