Open-cut type self-protective construction method of city comprehensive prefabricated pipe rack and self-propelling laying machine

A laying machine, self-propelled technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of long backfilling time, difficult backfill settlement control, and high construction costs, reducing the excavation area and saving municipal expenses. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

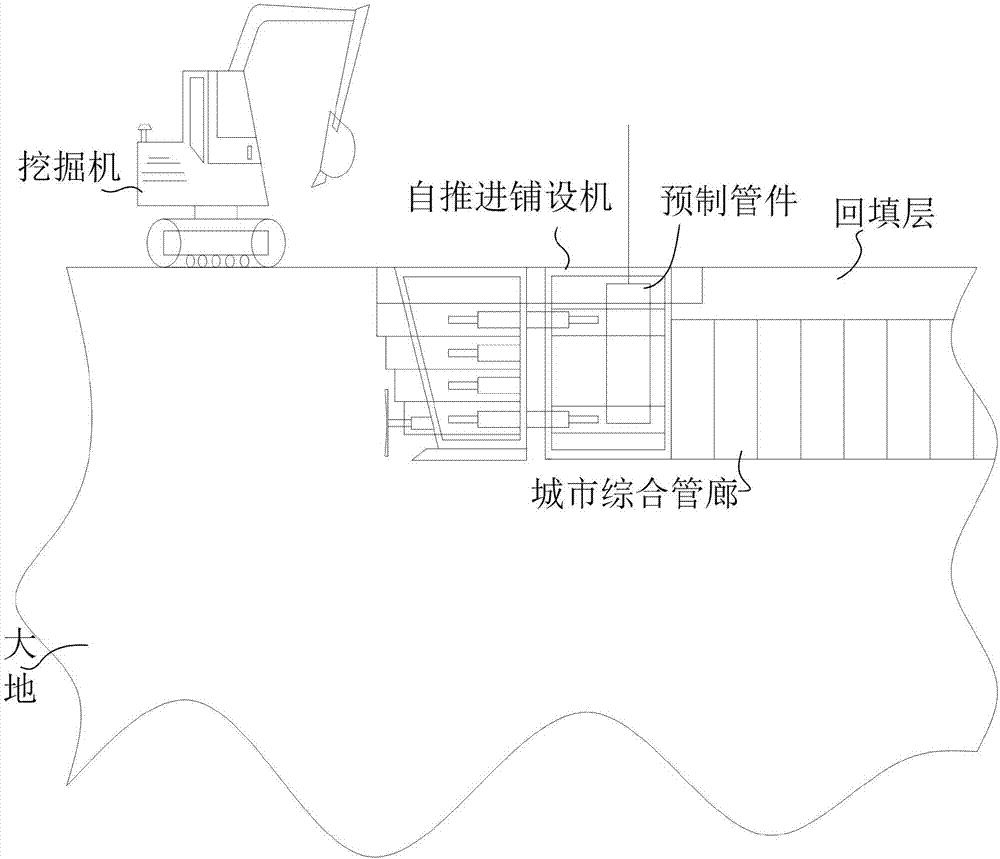

[0032] Example 1, such as figure 1 As shown, this embodiment provides an urban comprehensive prefabricated pipe corridor open-cut self-protection construction method. Specifically, this embodiment describes in detail that the width of the prefabricated pipe fittings is 2.7m and the laying depth is 8m.

[0033] First of all, here is a detailed description of the traditional process. In the traditional construction for this type of work, the width of the ground that needs to be excavated is about 13m, and the width of the lowest part is about 3.5m. Then, use the gantry crane to place the prefabricated pipe fittings into the excavated open ditch, and then the workers adjust the corresponding position to ensure that there is no deviation, then fix them, and then backfill, due to the backfill process on both sides of the prefabricated pipe fittings , cannot be compacted with a road roller, so a little bit of manual compaction is required. Due to the limited degree of manual compact...

Embodiment 2

[0041] Embodiment 2, this embodiment provides a self-propelled laying machine, and its utility model patent was applied for on the same day under the name of self-protection self-propelled laying machine for urban comprehensive pipe gallery.

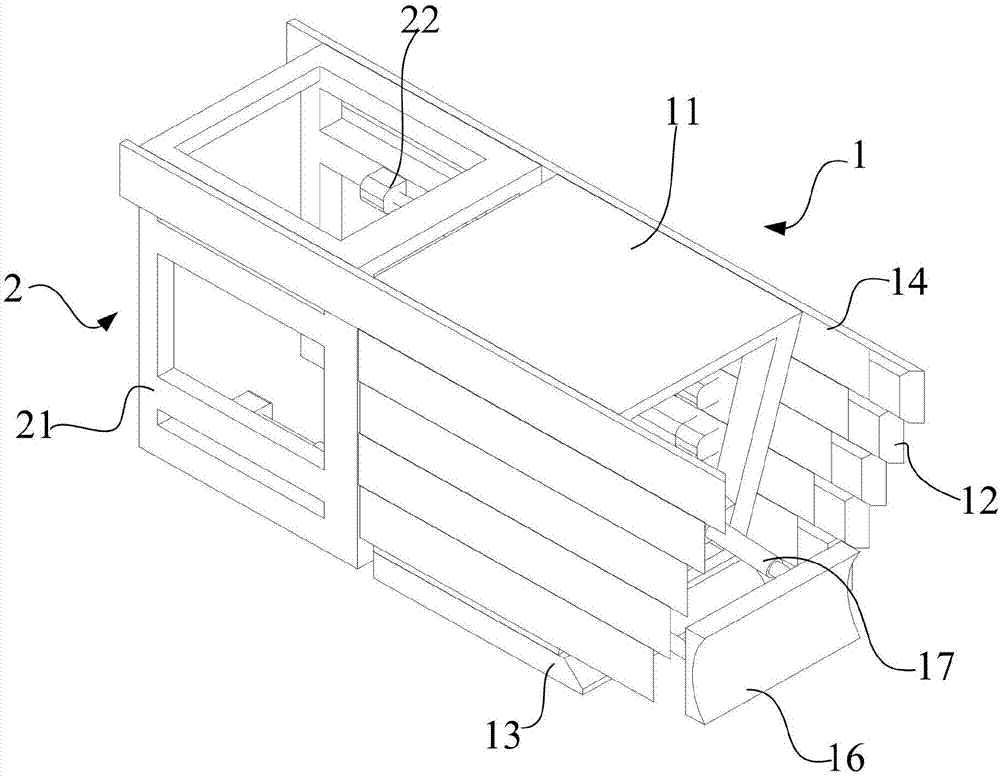

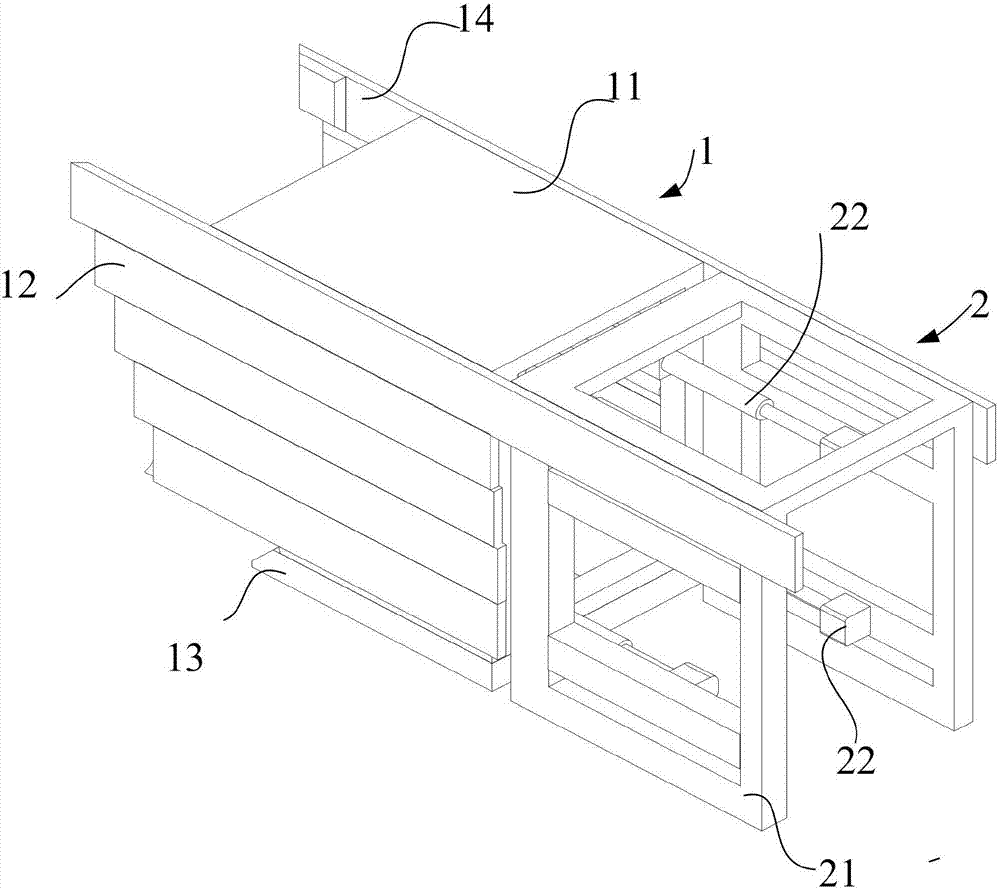

[0042] Such as figure 2 , image 3 , Figure 4 As shown, the present embodiment provides a self-propelled paver, including a shoveling part 1 and a laying part 2 connected to each other. Part 2 is mainly used for laying prefabricated pipe fittings to achieve the purpose of urban comprehensive pipe gallery construction. It should be noted here that the structure provided in this embodiment is limited to the laying of urban comprehensive pipe gallery with an excavation depth below 8m.

[0043] In order to achieve the above purpose, in this embodiment, the provided shoveling section 1 includes a frame-shaped shoveling section body 11 and shoveling boards 12 arranged on both sides of the shoveling section body 11. The whole body 11 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com