Method and structure for excavating soil in core tube region based on raft pile supporting

A core tube and wooden raft technology, which is applied in excavation, infrastructure engineering, construction, etc., can solve the problems that large machinery cannot enter the site for operation and the adverse effects of the construction period, so as to reduce the labor load of workers and reduce the excavation area of earthwork , high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as a basis for any limitation of the present invention.

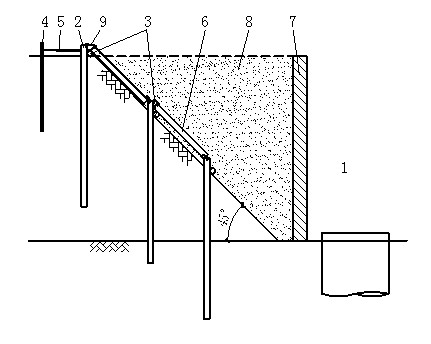

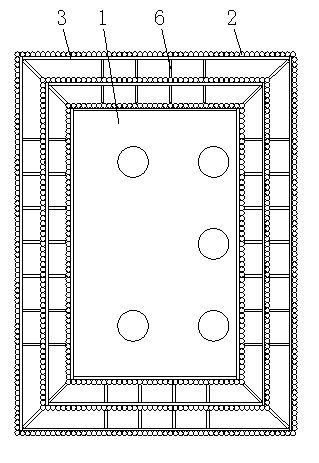

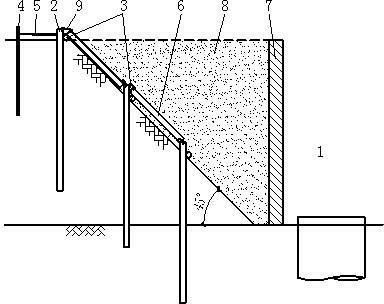

[0029] Embodiments of the present invention: the structure of the present invention is as figure 1 and figure 2 Shown, when implementing the method for the earthwork of a kind of wooden row pile supporting excavation core barrel area of the present invention, operate according to the following steps:

[0030] A. According to the length and width requirements of the foundation pit, vertically drive the first layer of wooden row piles one by one on the edge of the foundation pit, and the length of the wooden piles constituting the wooden row piles is 4 meters;

[0031] B. Fix a circle of horizontal wooden piles with door-shaped nails on the side of the foundation pit of the first layer of wooden row piles;

[0032] C. Drive steel ground anchors vertically into the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com