Construction method for spiral barrel-shaped foundation

A technology of foundation construction and spiral barrel, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve the problems of high labor intensity, long construction period, and inapplicability, and achieve small excavation area, shorten construction period, and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

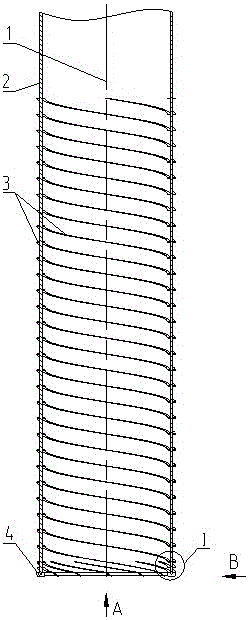

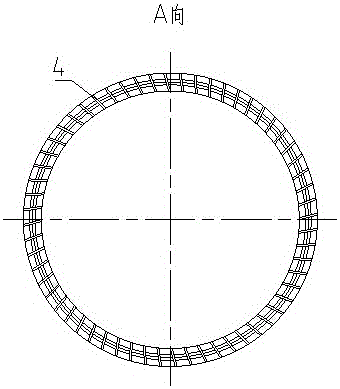

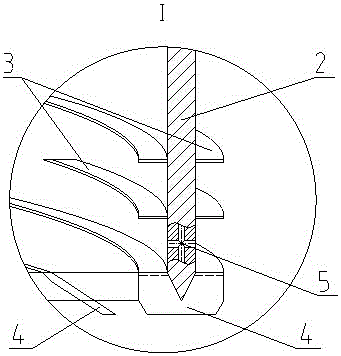

[0042] Such as Figure 1-Figure 4 As shown, the prefabricated spiral cylindrical foundation 1. It consists of a cylinder 2, a helical blade 3, a cutter 4 and a nozzle 5, etc. The bottom of the cylinder 2 is open, and the inner and outer walls are provided with helical blades 3. The helical blades 3 can be of multi-tooth structure and can be arranged intermittently or partly intermittently; The bottom of the spiral cylindrical foundation 1.

[0043] Such as Figure 5 As shown, the spiral cylindrical foundation 1 is erected at the set position;

[0044] Such as Image 6 As shown, the spiral cylindrical foundation 1 is rotated under the action of power, and the bottom cutter 4 cuts the rock and soil in the annular area corresponding to the bottom of the cutter 4 during the rotation, and the excess rock and soil are output by the spiral blade 3; in the soft soil foundation Also can not have cutting tool 4 under the environment and directly cut the rock and soil in the annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com