Bridge pier capping beam hoop steel beam template system and construction method thereof

A formwork system and beam-covering technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as the need to adjust the formwork type, the unsightly sealing of the tension slot, and the impact on the aesthetics of the beam surface. , to save the construction cost and time, save the cost of hardening treatment, and reduce the difficulty of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings of the description.

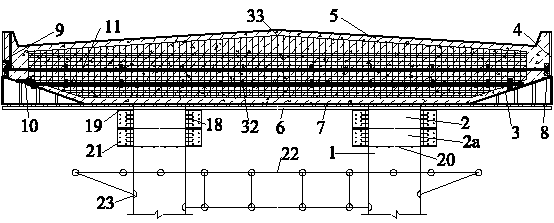

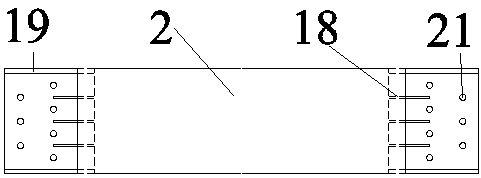

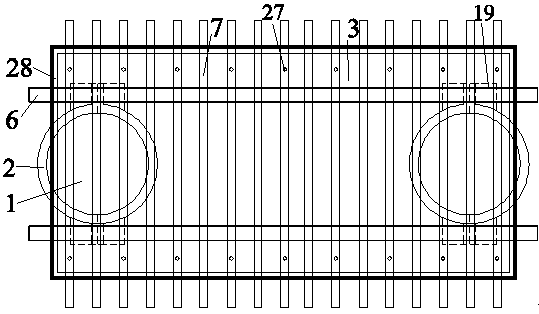

[0038] like Figure 1-11As shown, the hoop steel girder formwork system of the bridge pier cover beam of the present invention includes a pier column 1, an upper hoop 2, a lower hoop 2a, a bottom form 3, an end form 4, a side form 5, a tensioning notch formwork 10, The crossbeam 6, the longitudinal distribution beam 7, the unit plug-in safety protection frame 22, the upper hoop 2 and the lower hoop 2a are connected by two semi-circular arc steel plates, and are connected to the pier column 1 through high-strength bolts 21 , the upper hoop 2 and the lower hoop 2a ends are provided with a hoop cover 19, and the hoop cover 19 at the upper end of the upper hoop 2 is provided with a hoop cover beam resting groove 24, and the crossbeam 6 passes through the hoop cover The beam shelving groove 24 is installed on the hoop cover plate 19, the longitudinal dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com