IOT-based Waste lubricating oil recycling system server and method

A waste lubricating oil and recovery server technology, applied in the field of waste lubricating oil recovery system, can solve the problems of easy occurrence of mixed oil, difficulty in sorting and recycling waste lubricating oil, and low effective recovery rate, so as to improve recycling efficiency and improve sorting and recycling Difficulty, the effect of reducing recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0027] According to the applicant’s research, it is found that the recycling of waste lubricating oil is a reverse liquid logistics system, and there is currently no mature and specialized technical solution, which can be said to be a technological gap. The current typical method is: the waste lubricating oil production unit uses ordinary metal oil drums (200L) to collect and store the lubricating oil replaced from the vehicle or equipment, and periodically notify the oil collection unit (or personnel) to come and collect the oil. Oil collectors usually use tricycles, small trucks or box trucks to pull waste lubricating oil and oil drums together, and transport them to the collection and storage points of oil collectors, and use ordinary oil tanks for centralized storage. When the waste lubricating oil has accumulated to a certain amount, it is transported to the processing unit by ordinary oil truck for processing and disposal. Such existing recycling methods lack professional...

no. 2 example

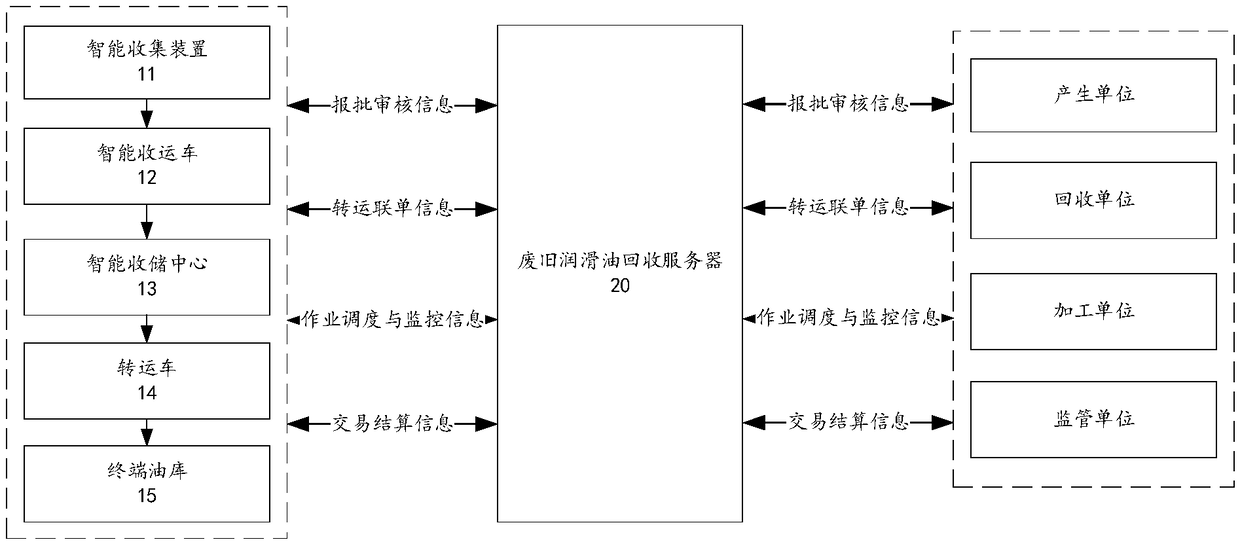

[0044] In order to enable the used lubricating oil recovery system 10 to cooperate with the operation of the Internet of Things technology, this embodiment also provides a used lubricating oil recovery server 20 based on the Internet of Things for scheduling the coordinated operation of various parts of the used lubricating oil recovery system 10 . The waste lubricating oil recovery server 20 can be divided into an M2M Internet of Things access system, a support system, and an application system.

[0045] Please refer to Figure 4 , Figure 4 It is a schematic structural diagram of a waste lubricating oil recovery server provided by the second embodiment of the present invention.

[0046] The M2M Internet of Things access system receives from the equipment side through the Internet of Things (a waste lubricant intelligent collection device 11, a waste lubricant intelligent collection and transportation vehicle 12, an intelligent storage center 13, a waste lubricant transfer vehicle...

no. 3 example

[0069] In order to cooperate with the waste lubricant recovery system 10 and the waste lubricant recovery server 20 to realize the recovery of waste lubricants, the third embodiment of the present invention also provides a waste lubricant recovery method based on the Internet of Things. Please refer to Figure 5 , Figure 5 This is a schematic diagram of the stages of a method for recycling waste lubricating oil based on the Internet of Things provided by the third embodiment of the present invention. The method for recycling waste lubricating oil based on the Internet of Things includes an approval review and information presetting stage, a sorted collection stage, a sorted collection and transportation stage, a sorted collection and storage stage, a transfer stage, and a circulation information processing stage. The specific steps are as follows:

[0070] S1 Approval review and information presetting stage: The waste lubricant producing unit uploads unit information, waste lub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com