Tapered optical fiber temperature sensor and sensing probe manufacture method thereof

A technology of temperature sensor and tapered optical fiber, which is applied to the manufacturing field of tapered optical fiber temperature sensor and its sensing probe, can solve the problems of complex temperature sensor manufacturing process, high requirements of detection device, high cost of detection circuit, etc., and achieves a simple structure. , easy to manufacture, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

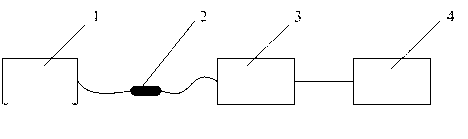

[0025] see figure 1 and figure 2 , the tapered fiber optic temperature sensor comprises a tapered fiber optic temperature sensing probe (2), characterized in that the input end of the tapered fiber optic temperature sensing probe (2) is connected to a light source (1); the tapered fiber optic The output end of the temperature sensing probe (2) is connected to the signal processing unit (4) through the optical detector (3); when the temperature around the cone area of the tapered optical fiber temperature sensing probe (2) changes, its cone area fades away The field changes accordingly, thereby changing the optical power output by the tapered optical fiber temperature sensing probe (2); the optical detector (3) converts the optical signal output by the tapered optical fiber temperature sensing probe (2) into The electrical signal is sent to the signal processing unit (4), and the temperature information is obtained by converting the voltage value. The above-mentioned tape...

Embodiment 2

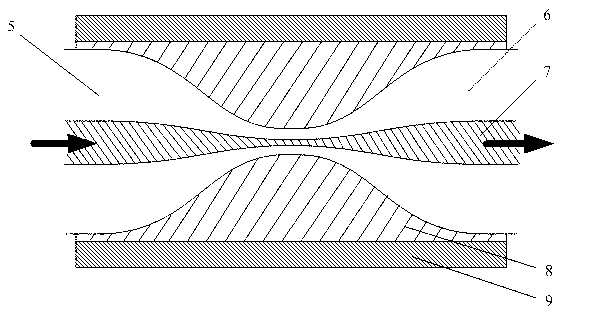

[0027] The manufacturing method of the tapered optical fiber temperature sensing probe is used for the production of the above-mentioned tapered optical fiber temperature sensing head, and its operation method is as follows:

[0028] 1) Take a section of optical fiber, peel off the coating layer to obtain a section of bare fiber, and repeatedly wipe the cladding of the bare fiber with alcohol for use;

[0029] 2) Slowly melt the bare fiber and taper, the taper speed is 0.1mm / sec, the longer the stretch length of the taper area, the smaller the diameter of the taper waist, the higher the sensitivity, and the stretch length is 10-20mm;

[0030] 3) Seal the drawn tapered optical fiber in the quartz U-shaped groove with epoxy glue;

[0031] 4) Coat the temperature-sensitive material (8) on the tapered region of the tapered optical fiber, and cover with a protective sleeve (9).

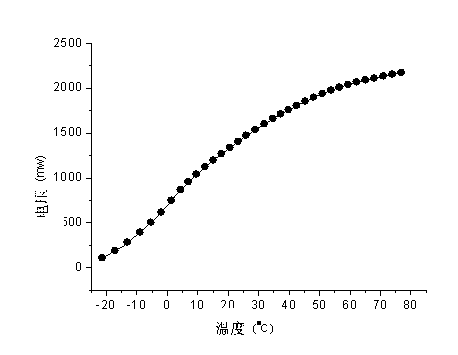

[0032] image 3 Shown in the high-sensitivity tapered optical fiber temperature sensor is the relatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com