Airport oil depot work simulating and training system

A simulation training and oil depot technology, which is applied to simulators, simulation devices for space navigation conditions, instruments, etc., can solve problems such as inability to install pipelines, leakage, and inability for students to visually observe the real-time flow of liquids, etc., so as to improve operational efficiency, Ease of operation and rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

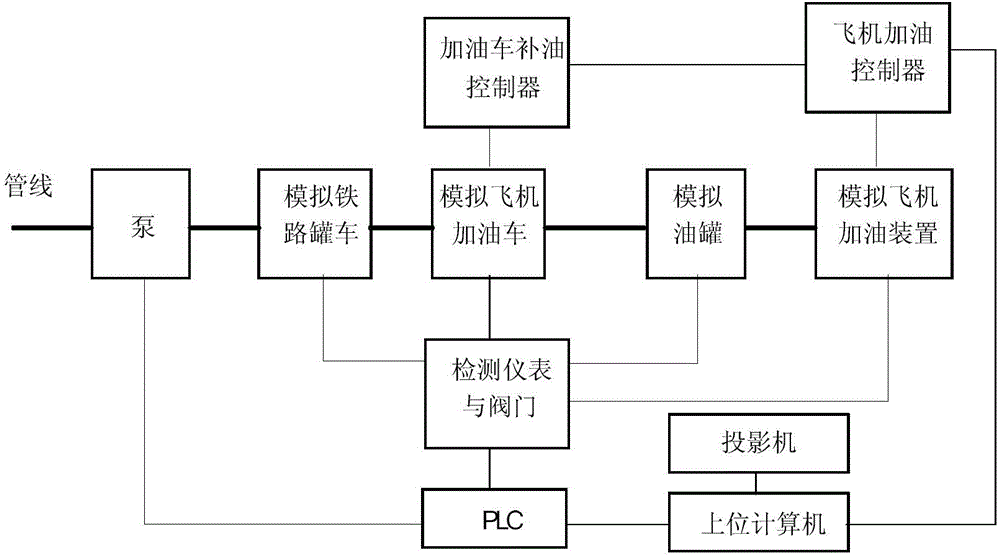

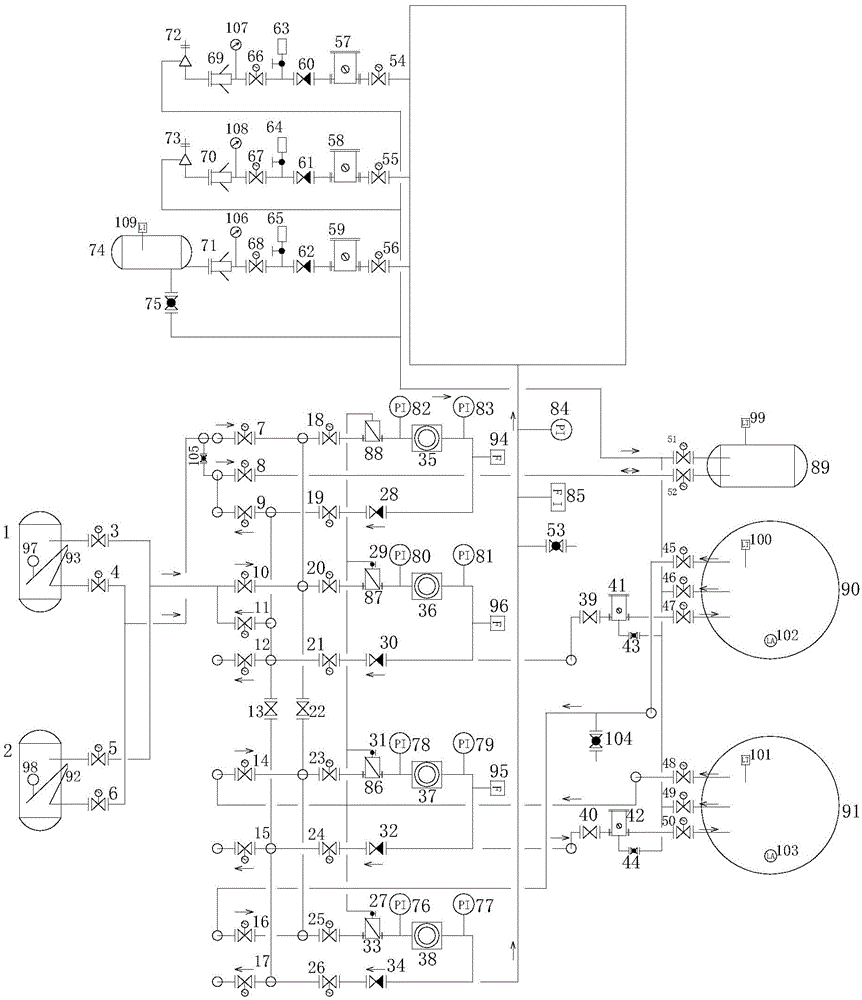

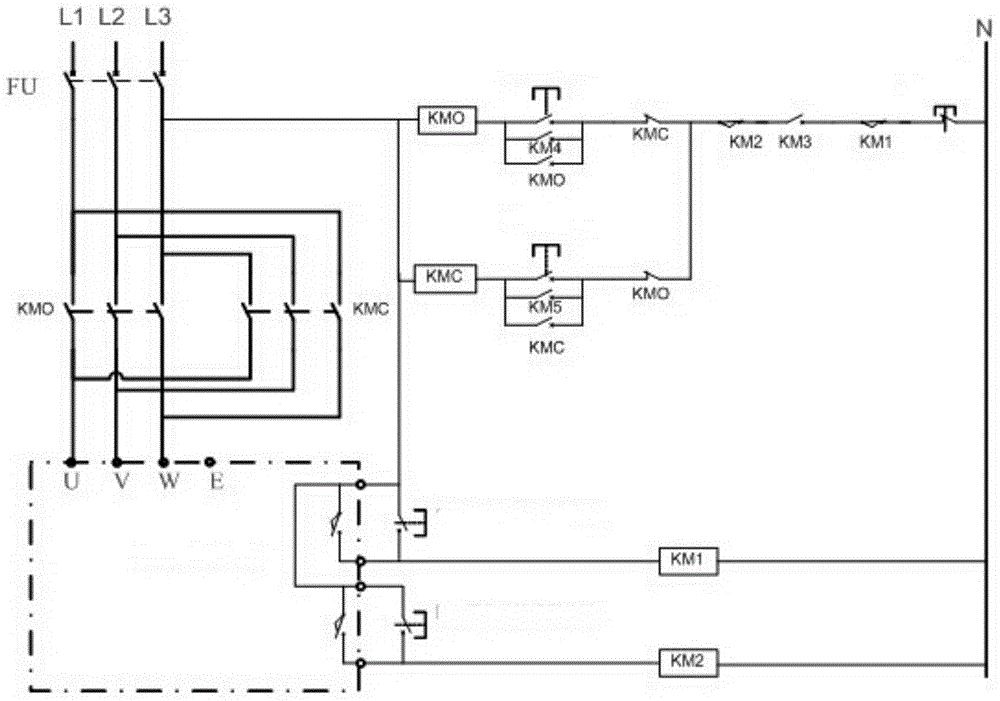

[0022] like figure 1 and figure 2 Shown: An airport oil depot operation simulation training system, including airport oil depot process simulation, airport oil depot operation process simulation, airport oil depot failure simulation, airport oil depot automation operation simulation and airport oil depot automation operation function simulation.

[0023] The technological flow simulation of the airport oil depot includes simulated railway tank cars, pumps, simulated oil tanks, simulated aircraft refueling vehicles, simulated aircraft refueling devices, valves, pipelines, simulated filters and simulated flow meters.

[0024] Through the opening and closing of valves, the operation process simulation of the airport oil depot can be simulated; the operation process simulation of the airport oil depot includes unloading oil from railway oil trucks, pumping bottom oil, pumping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com