Antistatic spark-free metal wear-resistant floor material and preparation method thereof

A floor material and anti-static technology, applied in the field of floor materials, can solve the problems of personal safety and national property loss, lack of anti-static, spark generation, etc., achieving various colors, good wear resistance, and small water-cement ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

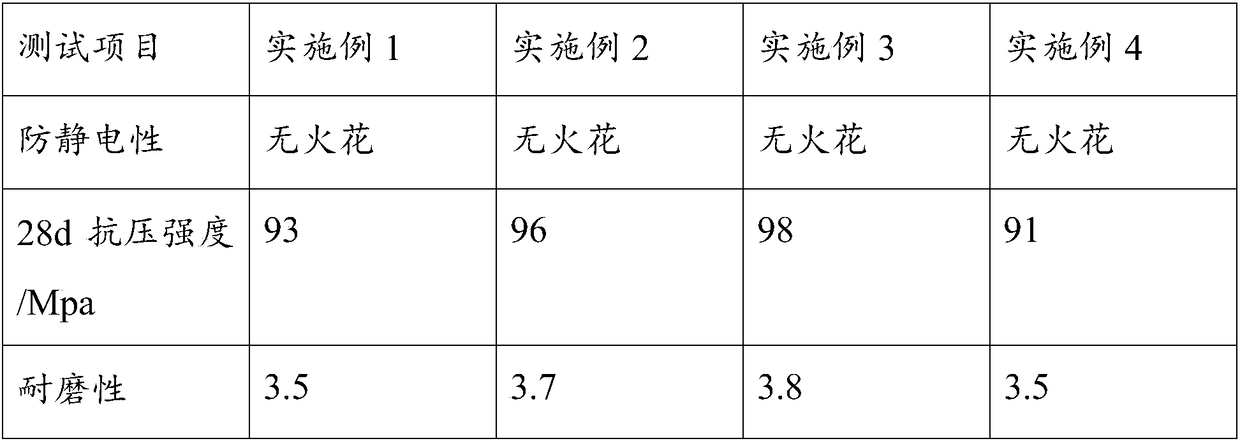

Examples

preparation example Construction

[0059] Preferably, the preparation method of the wear-resistant non-fired metal aggregate specifically includes the following steps:

[0060] (A) crushing iron ore sand containing more than 85% to 60-200 mesh particles, magnetic separation and impurity removal, and screening to obtain more than 90% of 60-200 mesh cemented carbide metal particles;

[0061] More preferably, the impurity removal operation is performed before the iron ore is crushed;

[0062] More preferably, the iron ore contains rare earth elements;

[0063] More preferably, the pulverization is performed using a rotary hammer mill;

[0064] More preferably, the screening is performed using a vibrating screen;

[0065] More preferably, the magnetic separation is operated by a magnetic separator;

[0066] (B) Calcining the cemented carbide metal particles obtained in step (A) at 1100° C. to 1400° C., adding foaming agent and metal powder for sintering and foaming, cooling the calcined and foamed material to ro...

Embodiment 1

[0086] The anti-static non-flammable metal wear-resistant floor material provided by this application specifically includes the following components:

[0087] 3.3 parts of cement, 5.8 parts of wear-resistant non-fire metal aggregate, 0.2 part of concrete admixture, 0.05 part of conductive material and 0.01 part of special additive.

[0088] The cement is a combination of ordinary Portland cement and sulphoaluminate cement with a grade strength of 42.5.

[0089] Concrete admixture is a combination of wear-resistant agent and water reducer.

[0090] Special additives are surfactants.

[0091] The conductive material is a combination of conductive mica powder and metal fibers.

[0092] Wear-resistant non-fire metal aggregate particle size 0.1mm ~ 1mm.

[0093] Wherein, the preparation method of the wear-resistant non-fire metal aggregate specifically includes the following steps:

[0094] A. Manually screen out impurities from the iron ore (containing rare earth) containing m...

Embodiment 2

[0102] The anti-static non-flammable metal wear-resistant floor material provided by this application specifically includes the following components:

[0103] 4 parts of cement, 6 parts of wear-resistant non-fire metal aggregate, 0.4 part of concrete admixture, 0.07 part of conductive material and 0.02 part of special additive.

[0104] The cement is a combination of ordinary Portland cement and aluminate cement with a grade strength of 42.5.

[0105] Concrete admixture is a combination of anti-corrosion agent and water reducer.

[0106] The special additive is a combination of surfactant and pigment.

[0107] The conductive material is a combination of conductive mica powder and graphite powder.

[0108] Wear-resistant non-fire metal aggregate particle size 0.5mm ~ 1.5mm.

[0109] Wherein, the preparation method of the wear-resistant non-fire metal aggregate specifically includes the following steps:

[0110] A. Manually screen out impurities from the iron ore (containing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com