Condensation method for oil gas recovery

A technology of oil recovery and condensation, which is applied in the field of environmental safety and energy utilization, can solve the problems of insignificant investment benefits, expensive low-temperature compressors, and large power consumption, and achieve the effects of simple structure, improved COP, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

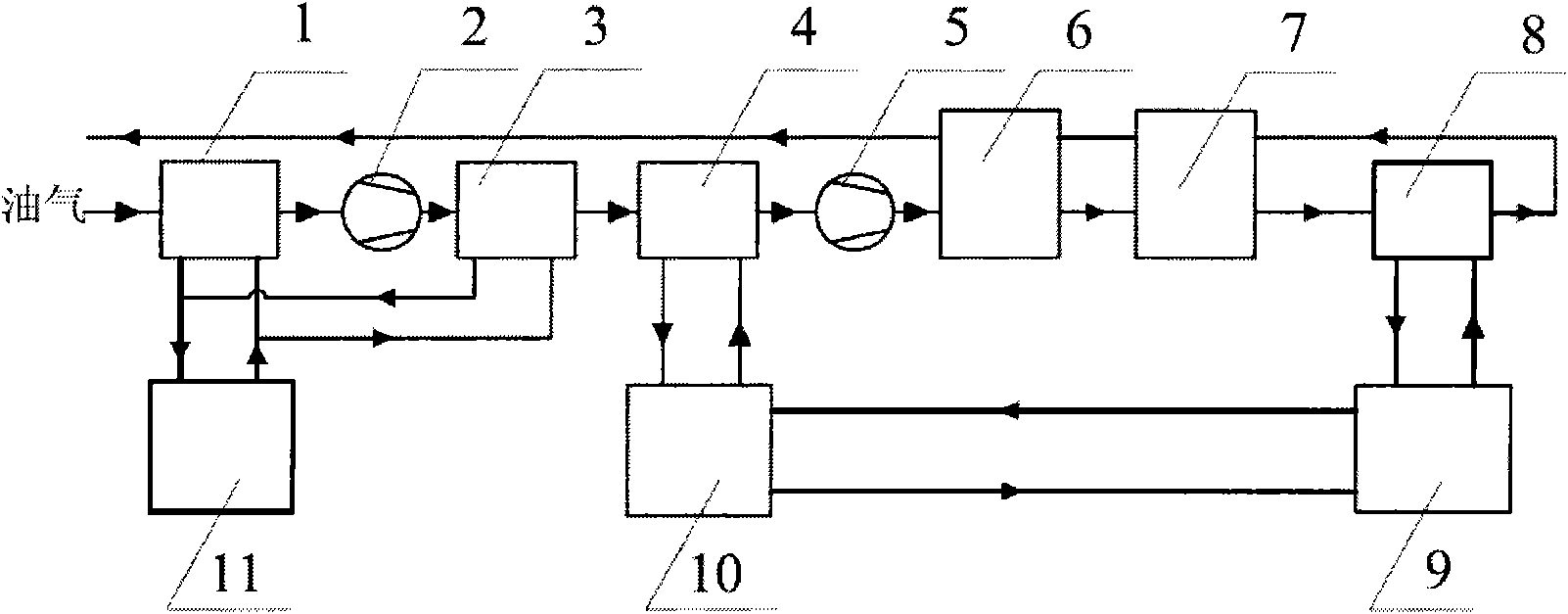

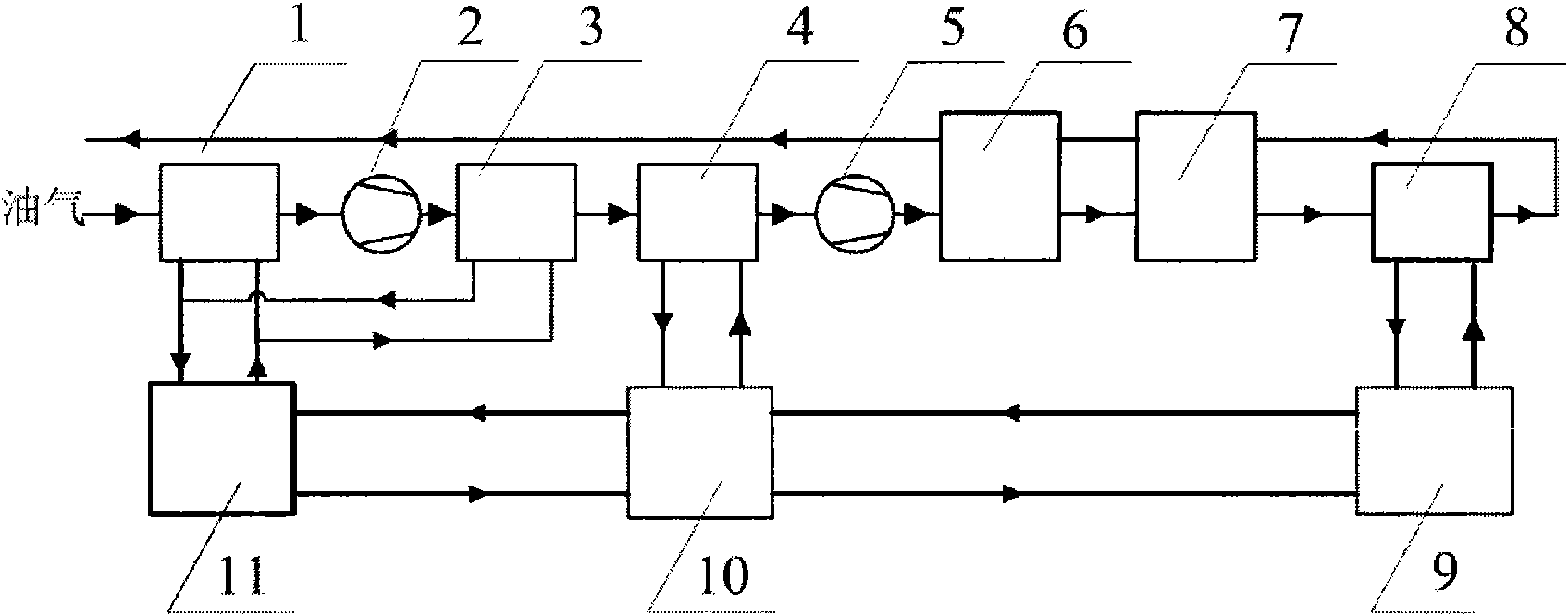

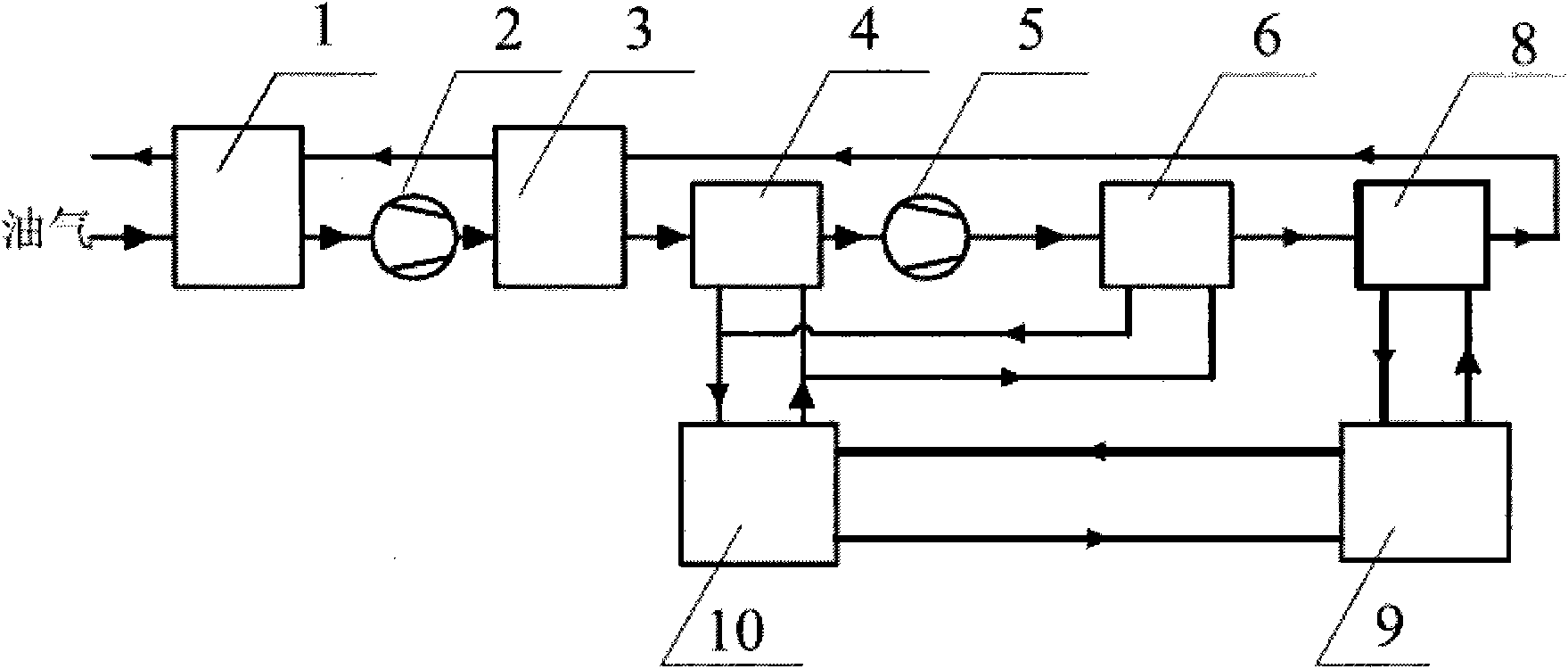

Method used

Image

Examples

Embodiment

[0048] Example: The oil-gas mixture of an oil and gas company as described in Table 1, which is characterized as an oxygen-free mixture with methane as the main component, and the purpose is to remove and recycle non-methane hydrocarbons in oil and gas.

[0049] Using ordinary condensation methods, when the cryogenic temperature is -81°C, the condensation recovery efficiency is less than 75%, which is far below the "Gas Station Air Pollutant Emission Standards" issued by the State Environmental Protection Administration and the General Administration of Quality Supervision, Inspection and Quarantine of my country. To meet the requirement of 95% recovery of non-methane hydrocarbon oil and gas, it is found through calculation that the cryogenic temperature should reach about -113°C. When the temperature is cooled to -80°C and further cryogenic cooling is required, liquid nitrogen is used for further cooling in engineering.

[0050] Table 1 Composition and concentration of oil-ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com