Oil gas recovery method

A recovery method and oil recovery technology, which is applied in the field of environmental safety and energy utilization, can solve the problems of large power consumption, waste of energy, and expensive low-temperature compressors, etc., and achieve the effects of reducing the requirements for insulation materials, increasing the condensation temperature, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

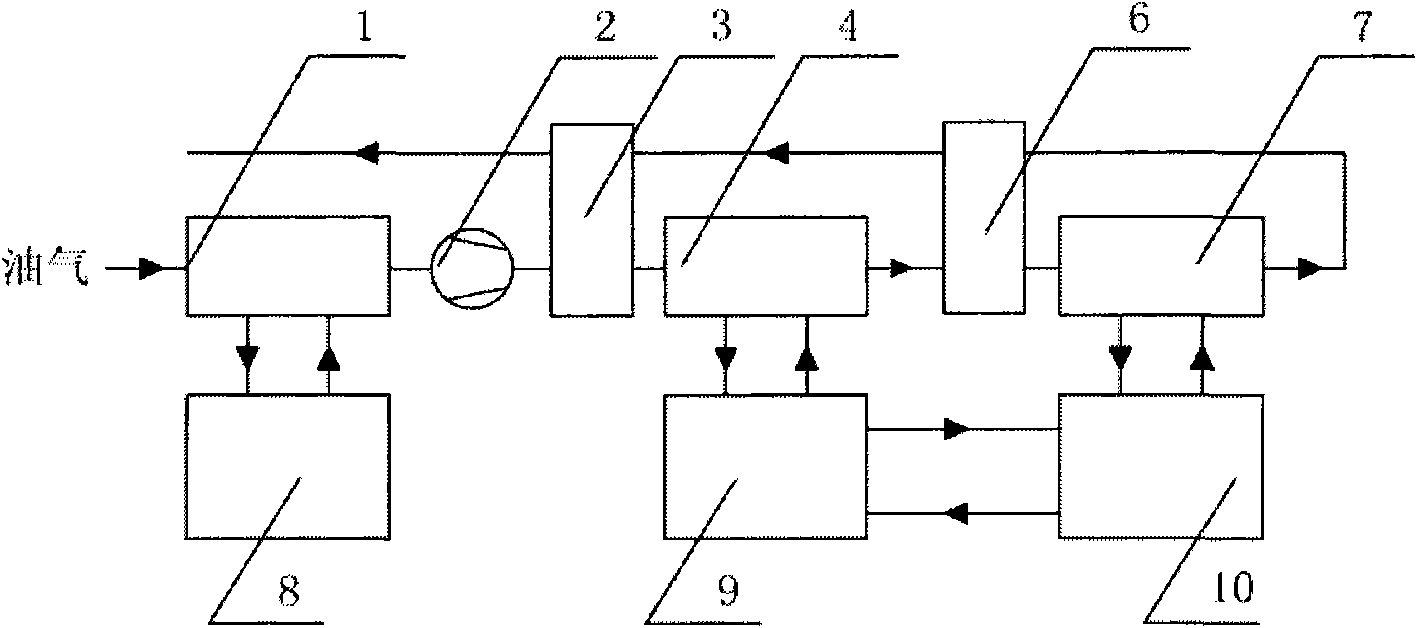

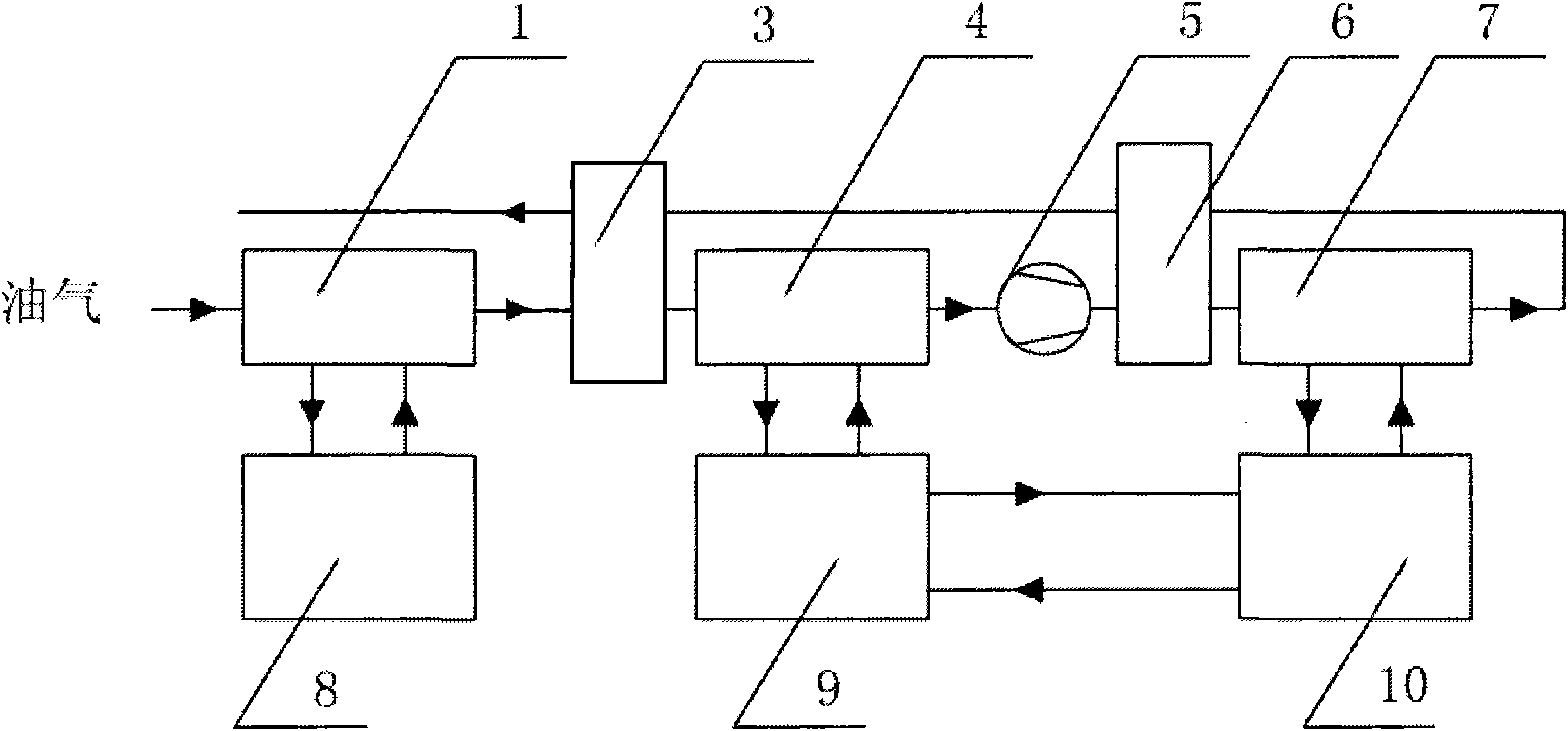

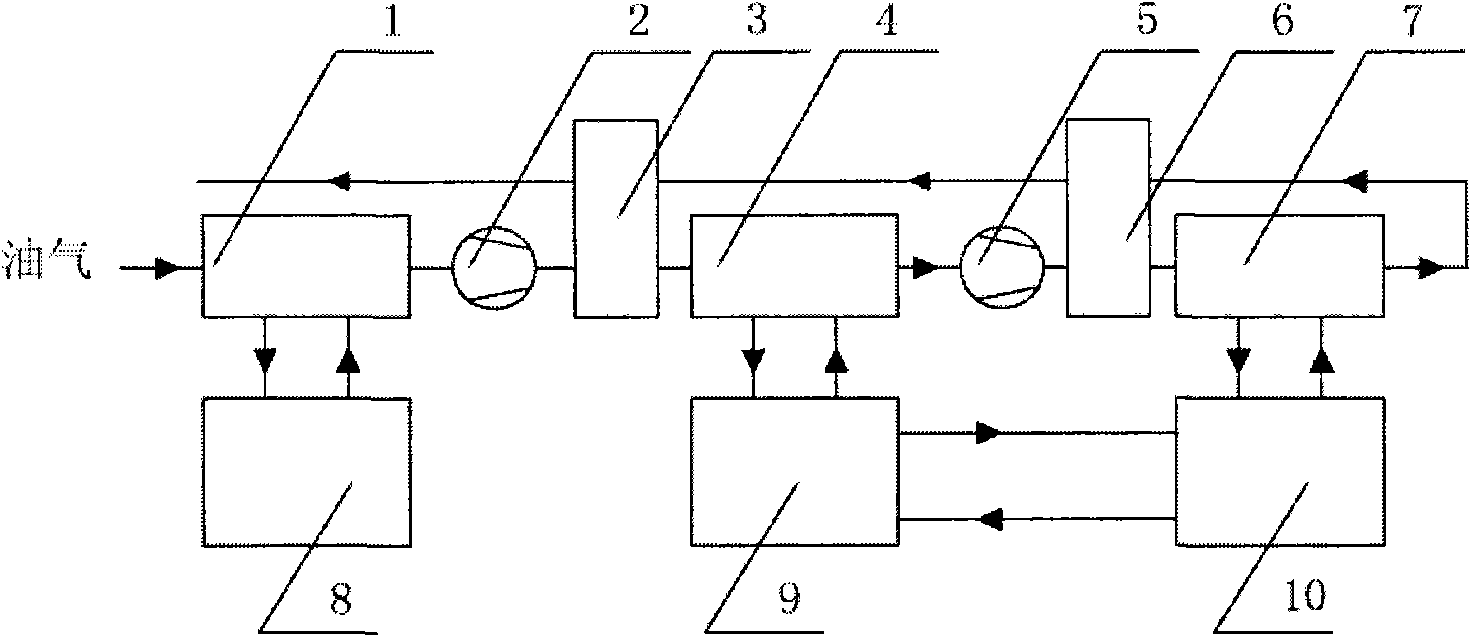

Image

Examples

Embodiment

[0070] The characteristics of the oil and gas recovery method are analyzed by using the oil and gas components loaded in a petrochemical plant described in Table 1, and the flow rate of the oil and gas mixture is 10mol / s. The characteristic of the oil and gas is that the volatilized oil and gas are mixed with air, and the volume concentration of oil is 33.35%. The purpose of oil and gas recovery is to condense the oil in the oil and gas into liquid and recover it.

[0071] Table 1 Composition and concentration of oil-gas mixture (1atm, 35℃)

[0072] substance

substance

0.68

cis-butene

3.10

ethane

1.24

6.00

1.40

n-pentane

3.68

Acrylic

0.30

n-Ethane

4.10

n-butane

3.70

52.69

5.60

14.01

trans-butene

3.50

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com