Oil depot oil-loading electrostatic monitoring system

A monitoring system and oil depot payment technology, applied in the direction of electrostatic field measurement, etc., to achieve the effects of avoiding accumulation, safe data collection, and preventing hidden dangers of electrostatic safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

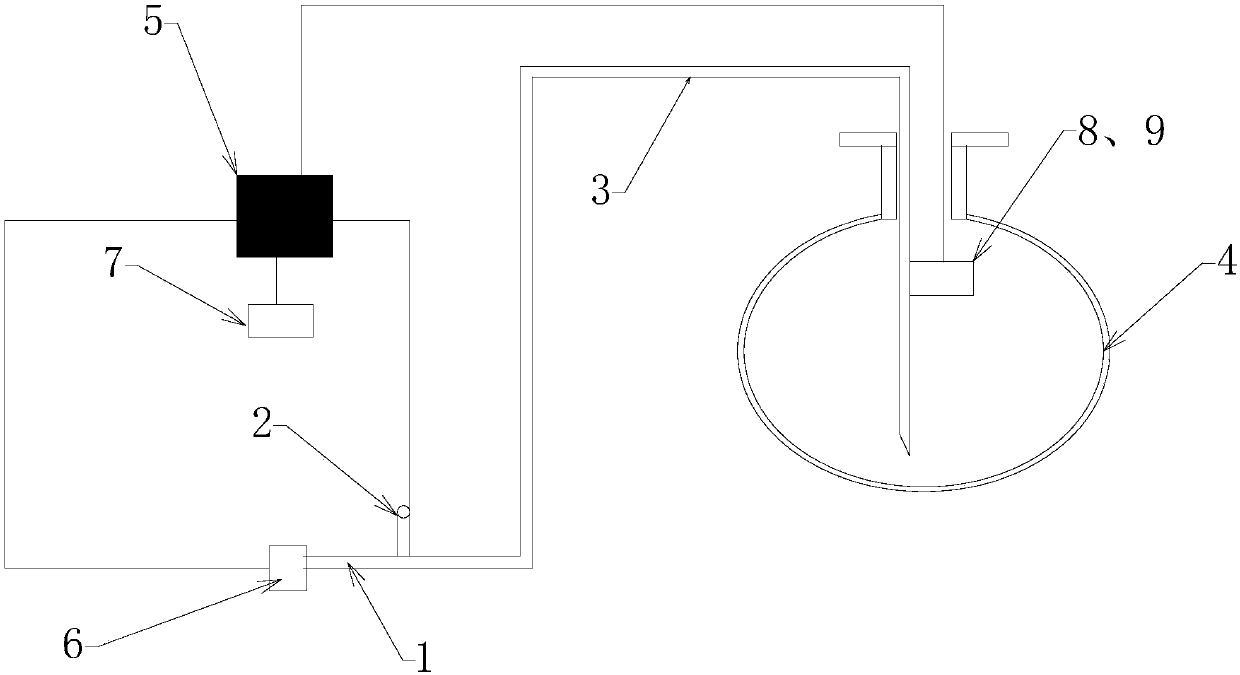

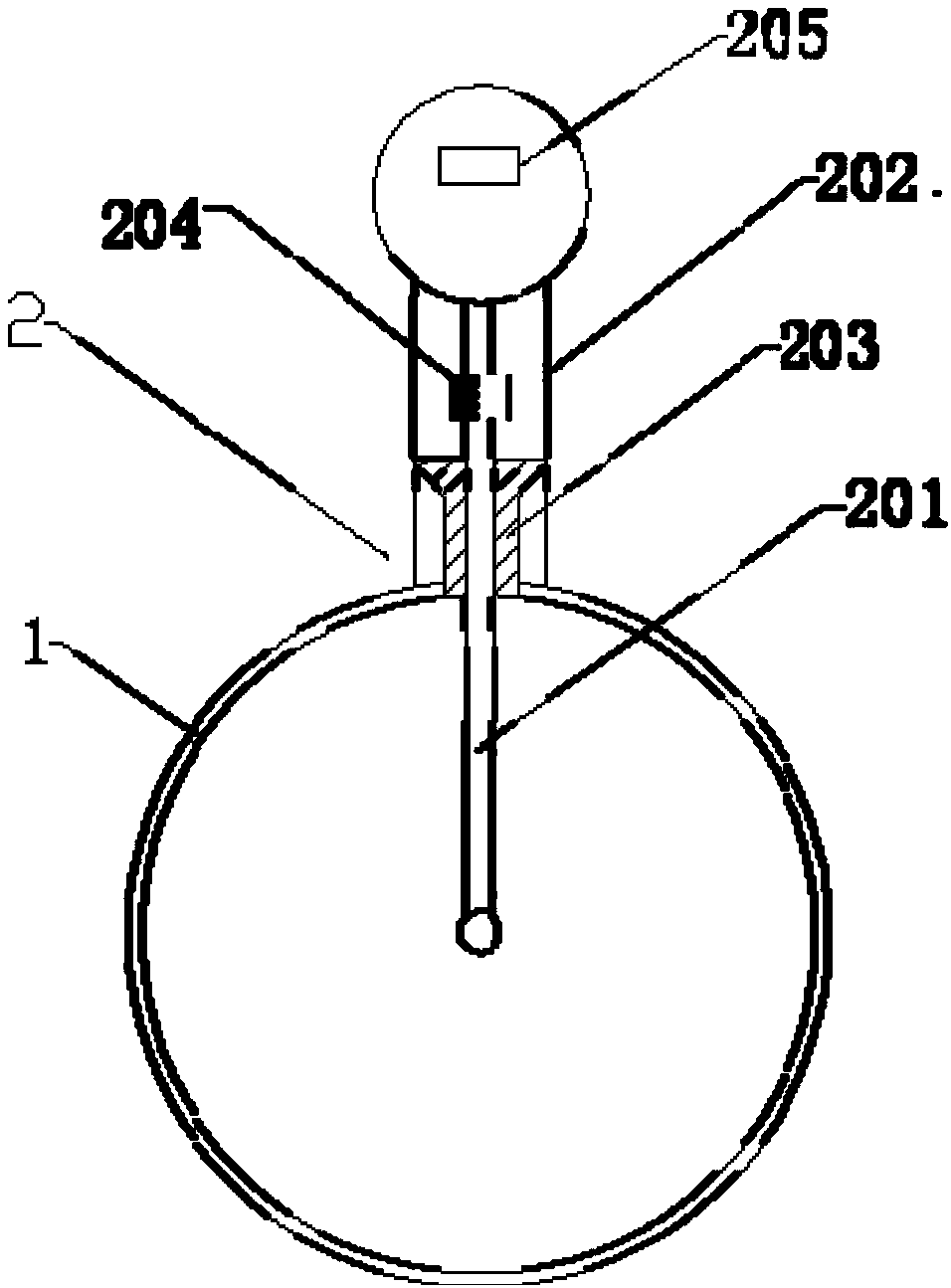

[0024] Such as figure 1 , figure 2 As shown, the present embodiment provides an oil depot electrostatic monitoring system for oil delivery. The oil delivery unit 6 is connected to the crane pipe 3 through the oil delivery pipeline 1, and the crane pipe 3 is inserted into the oil tank 4. The oil flow charge density meter 2 passes through the flange or belt A threaded pipe is fitted on the delivery line 1 . The oil flow charge density meter 2 is provided with a metal flameproof casing 202, and the metal flameproof casing 202 is grounded, so that the oil flow charge density meter 2 is well flameproof. The oil flow charge density meter 2 includes a ball sensor 201, a piezoelectric ceramic sensor 204, and a data processing module 205. The ball sensor 201 is located inside the oil delivery pipeline 1, and a polycarbonate sensor is arranged between the ball sensor 201 and the oil delivery pipeline 1. The insulating layer 203 made of vinyl fluoride material, and the insulating laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com