Magnetic head installing method and structure based on same

An installation method and magnetic head technology, applied in the configuration/installation of recording head, magnetic recording, instruments, etc., can solve the problems of thick card scratcher, inconvenient disassembly and assembly of the magnetic head, etc., and achieve reduced thickness, convenient disassembly and assembly, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

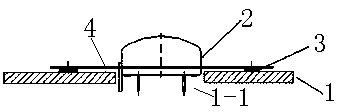

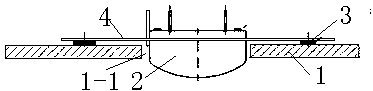

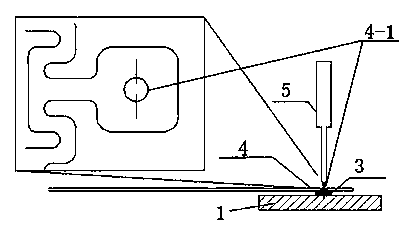

[0025] refer to figure 1 , figure 2 , image 3 and Figure 4 , the present invention relates to a kind of magnetic head installation method, carry out as follows:

[0026] 1) A metal shrapnel is preset on the magnetic head to ensure that the magnetic head can move back and forth in the vertical direction;

[0027] 2) A magnetic head window for accommodating the magnetic head is provided on the PCB;

[0028] 3) Solder the two positioning pieces on both sides of the magnetic head window of the PCB board respectively through the surface mount process;

[0029] 4) Weld one end of the metal shrapnel to a positioning piece;

[0030] 5) Weld the other end of the metal shrapnel to the other positioning piece.

[0031] In step 1, the metal shrapnel and the magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com