High-pressure sealing method and sealing ring

A high-pressure sealing and sealing ring technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems affecting the stability and sealing of bolt installation, loss of property and life, and easy leakage of sealing rings, etc., to achieve good performance Reusable performance, waste reduction, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. But it is not used as any limitation basis for the present invention.

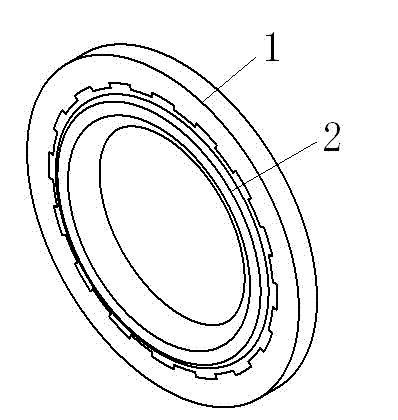

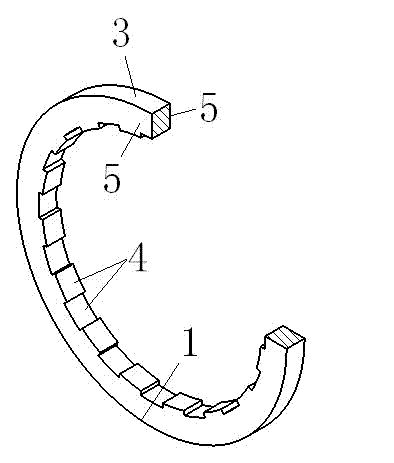

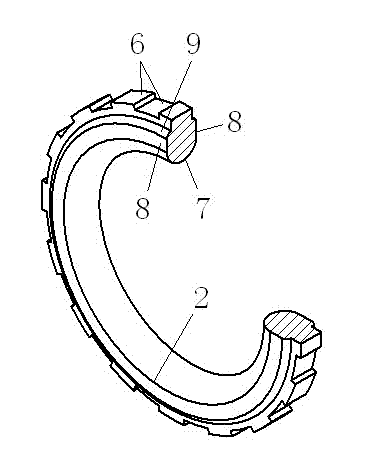

[0023] Example. A high pressure sealing method such as figure 1 As shown, the method of molding the rubber ring and the limit ring into one body is adopted, and the rubber ring is supported by the limit ring to prevent the non-circular deformation of the rubber ring. At the same time, the limit surface of the limit ring at both ends limits the maximum Deformation to achieve maximum sealing pressure. Such as image 3 As shown, the section of the rubber ring is designed as an apple-shaped section; the apple-shaped section includes two sealing surfaces, two transitional arc surfaces and the inner ring arc convex surface; the radial pressure is sealed through the two sealing surfaces; the inner ring arc convex surface is sealed Axial pressure: Control the inward flow o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com