Low friction high-pressure blade rotating motor based on self-compensation compound seal technique

A compound seal and low friction technology, which is applied in the direction of rotary piston pumps, rotary piston machines, rotary piston engines, etc., can solve the problems of poor sealing performance, small spring seal pressure, and limited application of rotary vane motors, etc., to achieve sealing Large pressure, reliable sealing performance, and the effect of expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

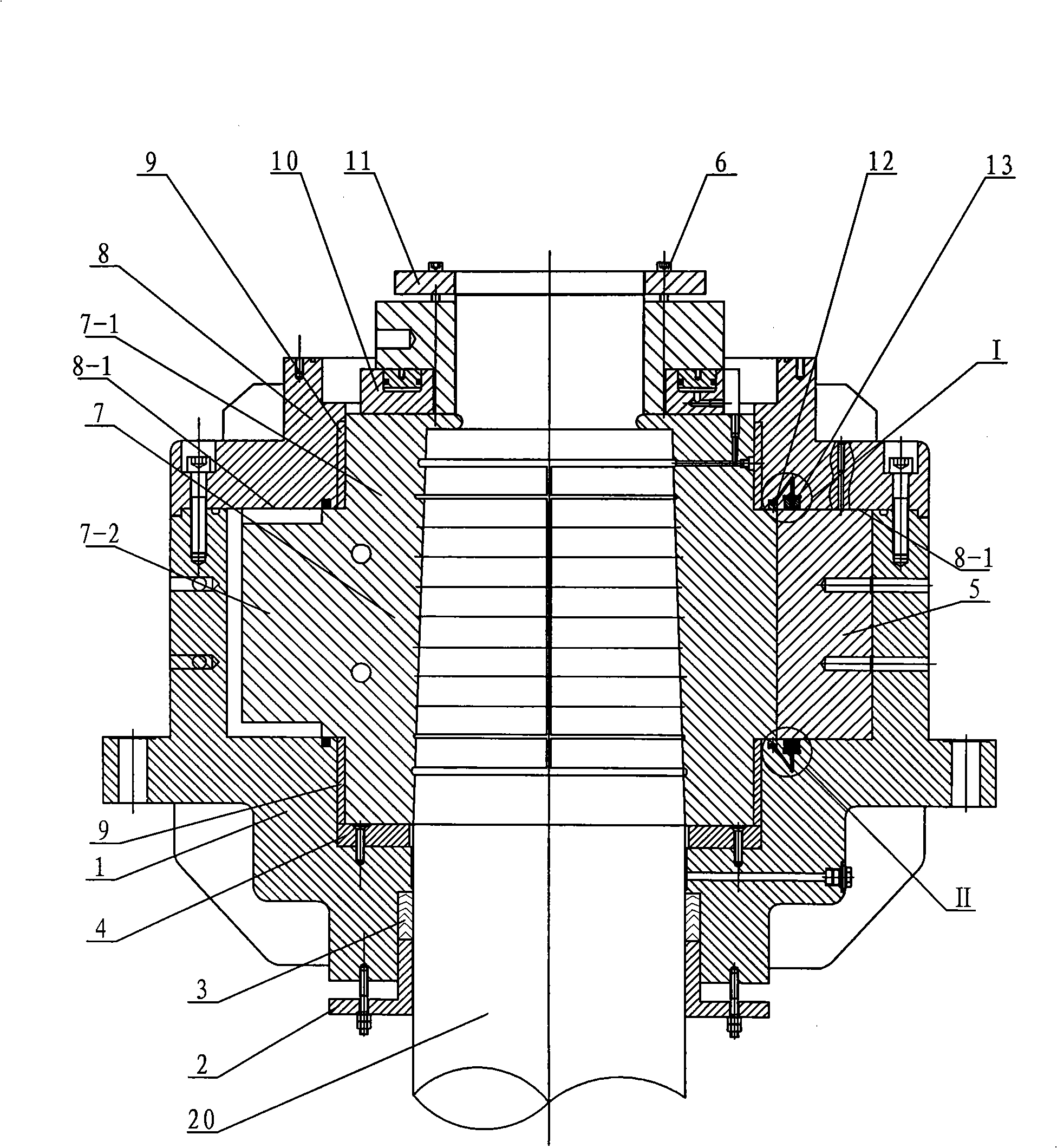

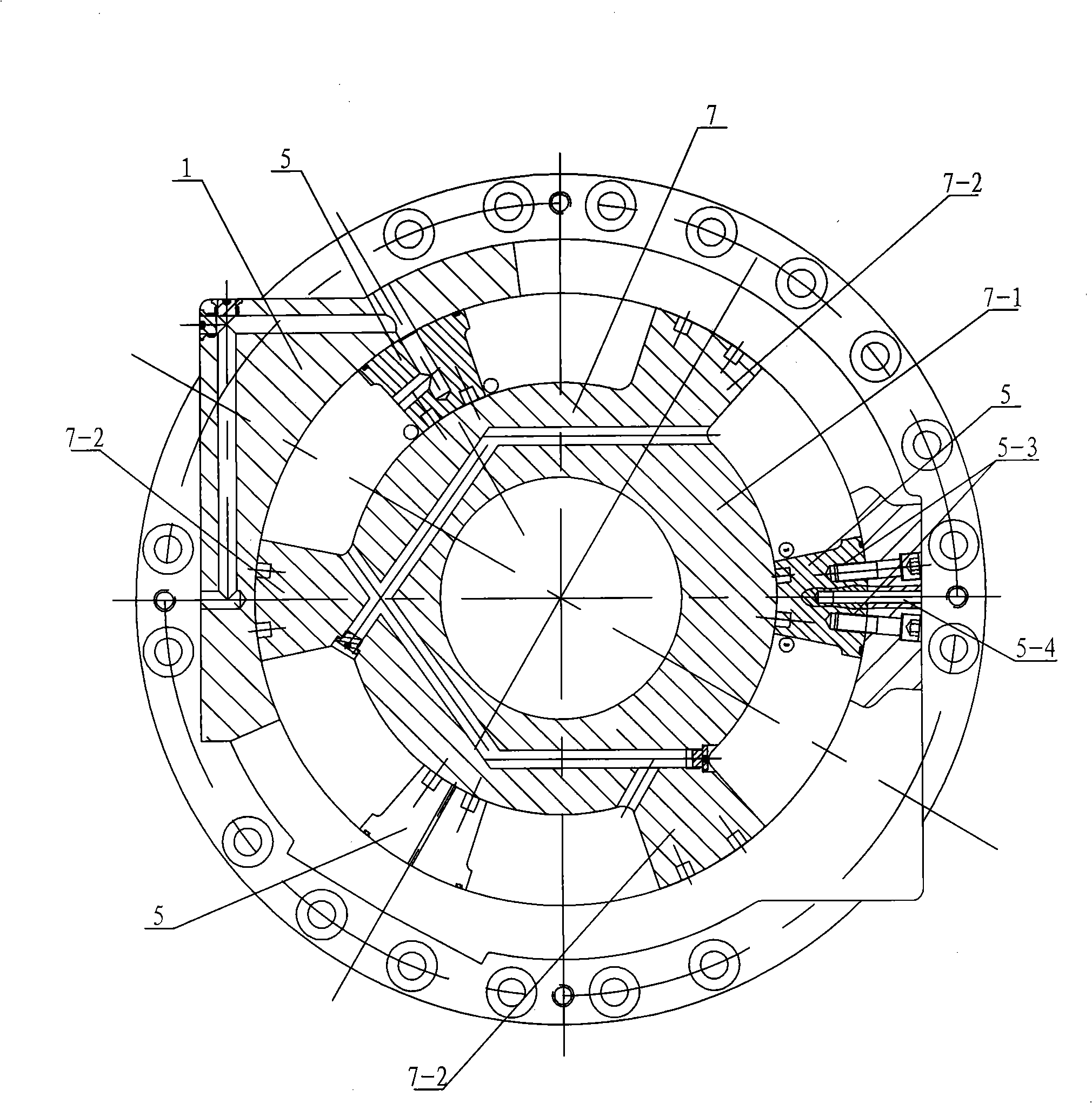

[0007] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this embodiment, which includes a housing 1, a lower end cover 2, a thrust bearing 4, a stator 5, bolts 6, a rotor body 7, an upper end cover 8, two sliding bearings 9, a pressing device 10, and an anti-loosening plate 11. Four one-way valve groups 15 and four sealing strips 16. The rotor body 7 is composed of the rotor shaft 7-1 and the moving blades 7-2. The moving blades 7-2 are evenly distributed from the cross-sectional direction of the rotor shaft 7-1. On the outer ring of the rotor shaft 7-1, the moving blade 7-2 is integrated with the rotor shaft 7-1, and the two sides of the moving blade 7-2 are respectively provided with a first valve slot 7-2-1, two second A first oil passage 7-2-2 is provided between the valve grooves 7-2-1, and two first straight grooves 7-2-3 are provided on the side end surface of the moving blade 7-2 in contact with the housing 1, A first oil hole 7-2-4 is provided...

specific Embodiment approach 2

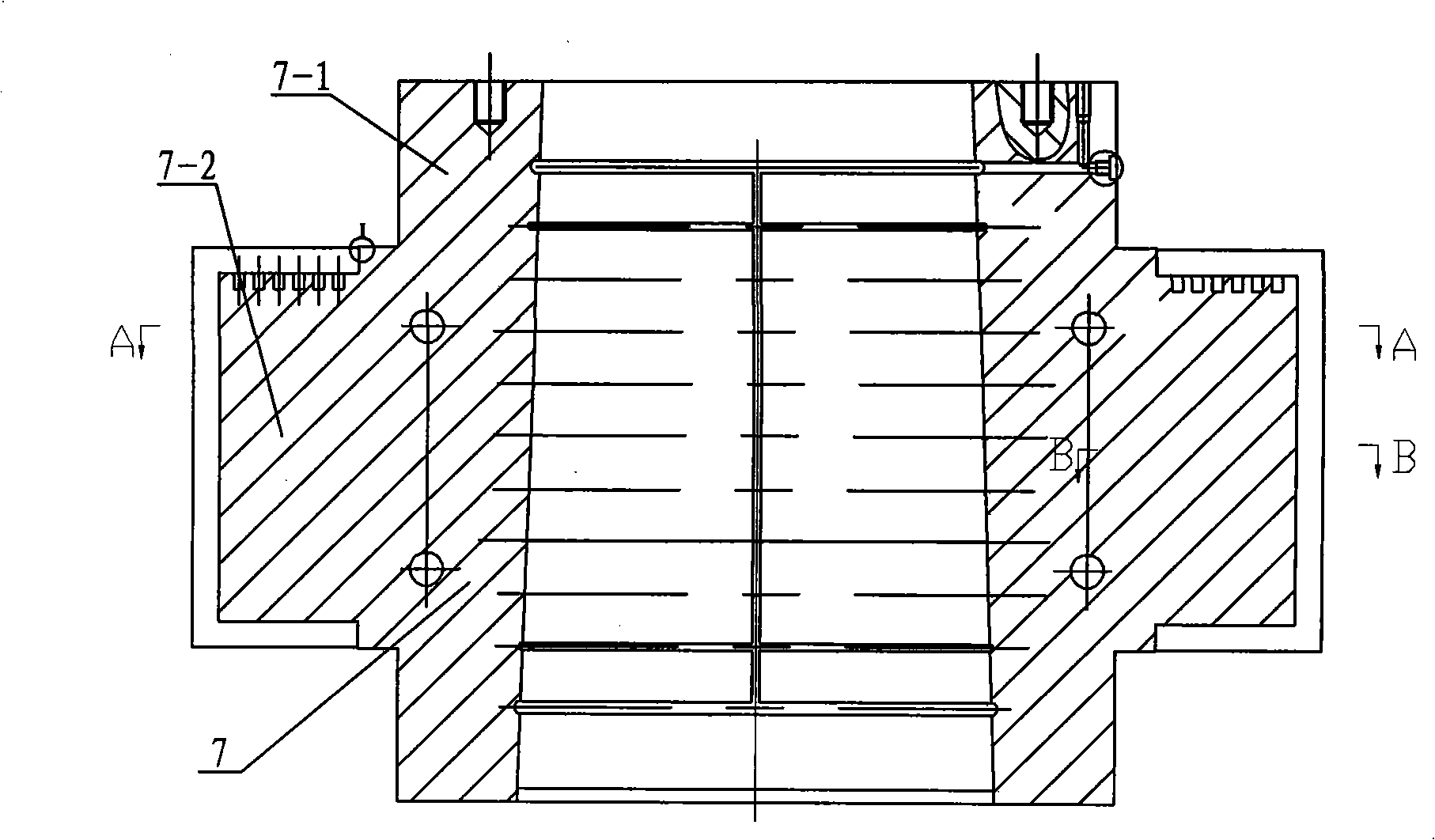

[0008] Specific implementation mode two: combination Figure 5 , Figure 7 and Figure 8 Describe this embodiment, the sealing strip 16 of this embodiment is composed of a sealing outer strip 16-1, a base 16-2 and two springs 16-3, and the sealing outer strip 16-1 corresponds to the first oil hole 7-2-4 Or one side of the second oil hole 5-5 is provided with a row of spring mounting holes 16-1-1, each spring mounting hole 16-1-1 is embedded with a base 16-2, and the spring 16-3 is arranged in the spring mounting hole 16 -1-1 and is set on the base 16-2, the sealing strip 16 has pressure equalizing grooves 16-1-2 on all three sides except the side where the spring mounting hole 16-1-1 is located, and the pressure equalizing grooves 16- 1-2 can reduce the pressure drop through the sealing strip, which is beneficial to improve the sealing effect. Sealing strip 16 cuts and forms with straight groove 5-6 on the stator 5, and base 16-2 selects No. 45 steel for use.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination Figure 8 To describe this embodiment, the distance between the top end of each base 16-2 and the top end of the sealing outer strip 16-1 in this embodiment is equal. This design makes the compression amount of each spring 16-3 the same and centered, so that the sealing strip 16 can fit well with the surface of the rubbed rotor shaft 7-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com