Ultrahigh pressure check valve

An ultra-high pressure, one-way valve technology, applied in the direction of control valves, valve devices, functional valve types, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

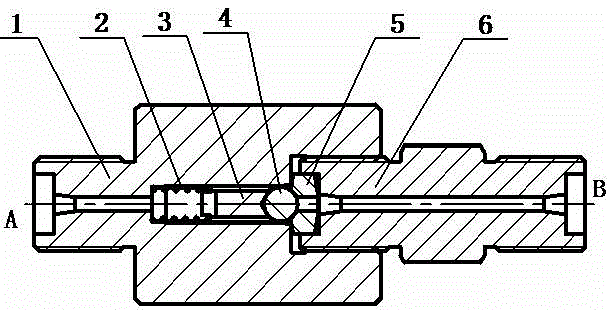

[0015] exist figure 1 In the illustrated embodiment of the ultra-high pressure hydraulic control check valve, the ultra-high pressure hydraulic control check valve includes a return spring 2 and a steel ball 4 arranged in the fluid channel of the valve body hole and connected to the valve core 3 . The return spring 2 is stuck on the stepped hole of the assembly channel of the valve body 1, one end of the valve core 3 is pressed against the return spring 2, and the spherical groove at one end presses the steel ball 4. The back-moving spring 2 is installed on the step hole in the valve body 1, and the right end of the spring is nested on the end of the spool 3, and the spool 3 presses the steel ball 4. The steel ball 4 rear end valve system has the stepped threaded hole screwed to the inlet joint 6. The inlet joint 6 which is shaped on the oil inlet B is threadedly connected with the valve body 1 . The axial end of the inlet joint 6 is provided with a medium flow channel stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com