Double-cylinder compression packer

A compression packer and hydraulic cylinder technology, which is used in sealing/packing, wellbore/well components, earth-moving drilling, etc. Peristalsis and other problems, to achieve the effect of prolonging the service life, uniform sealing pressure, and increasing sealing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

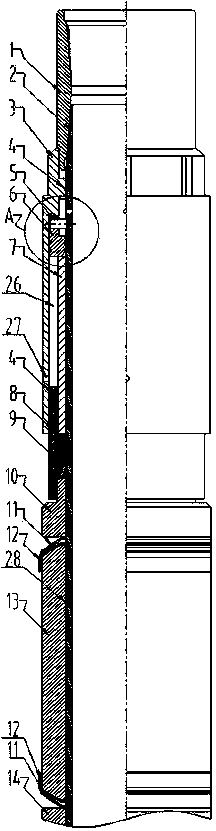

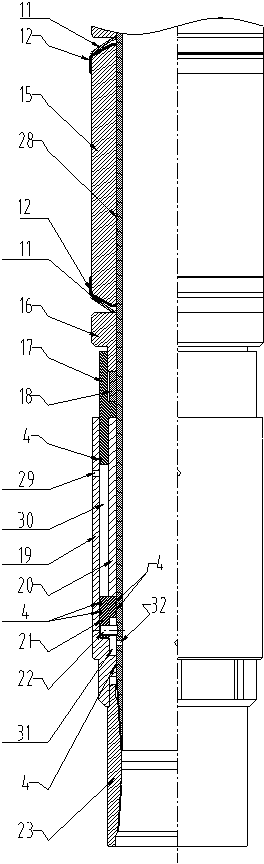

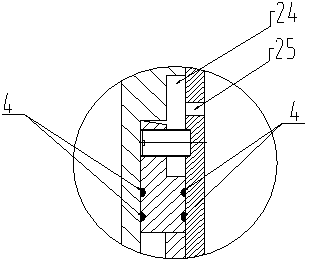

[0028] Such as Figure 1 to Figure 8 As shown, a double-cylinder compression packer includes a center pipe 2, and the upper joint 1, the upper liquid cylinder 3, the upper actuator 6, the upper piston 7, and the upper propulsion ring are sequentially installed on the center pipe 2 from top to bottom. 8. Upper moving ring 9, upper pressure ring 10, upper rubber cylinder 13, spacer ring 14, lower rubber cylinder 15, lower pressure ring 16, lower moving ring 18, lower push ring 17, lower piston 20, lower starter 21, The lower liquid cylinder 19 and the lower joint 23, the upper joint 1 is threadedly connected with the top of the central pipe 2, the upper end of the upper liquid cylinder 3 is threaded with the upper joint 1, and the upper actuator 6 and the upper piston 7 are located in the cavity of the upper liquid cylinder 3 , and the upper actuato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com