Immersion self-adapting seal control device used for photo-etching machine

A self-adaptive sealing and control device technology, applied in the direction of photolithography exposure device, microlithography exposure equipment, etc., can solve the problems of filling flow field pressure fluctuations, increasing liquid leakage, interference force, etc., to achieve flow field High stability, avoid air bubble entrainment, reduce the effect of internal power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

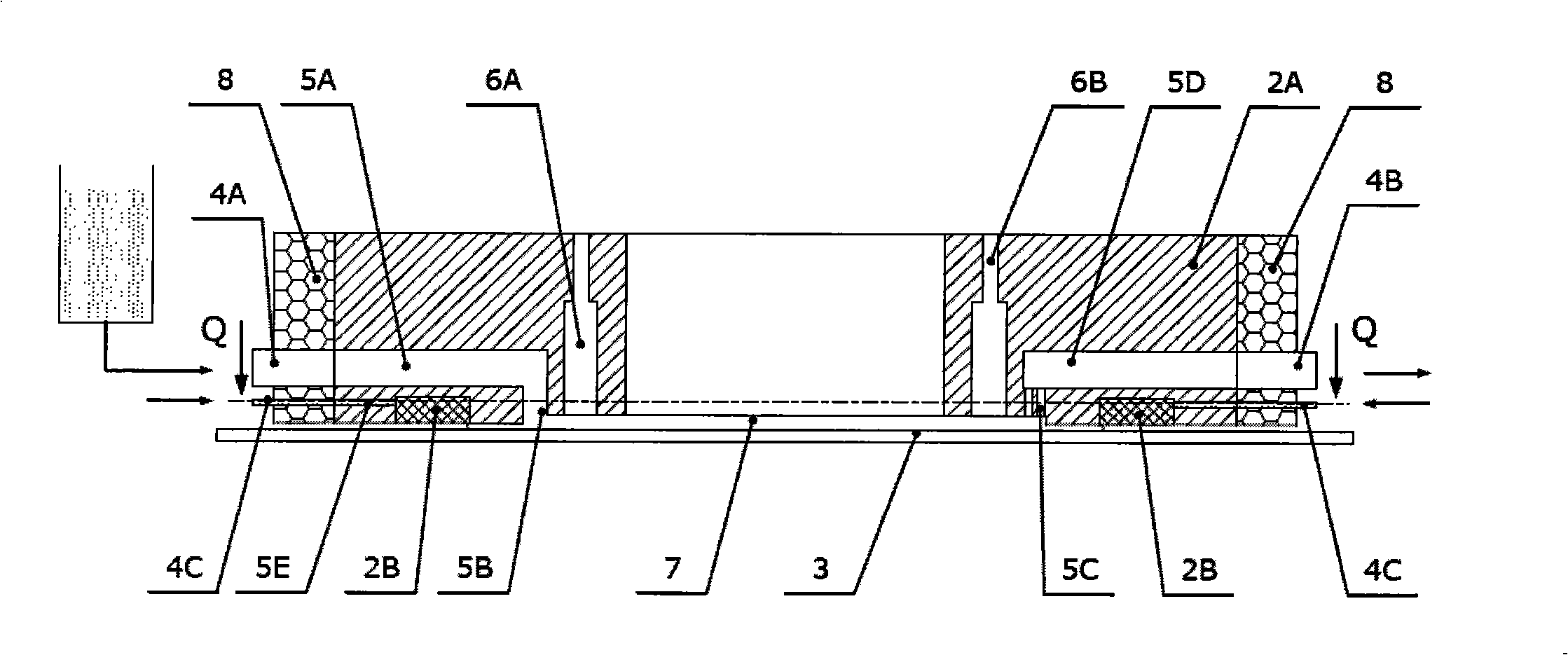

[0040] The present invention will be further described below in conjunction with drawings and embodiments.

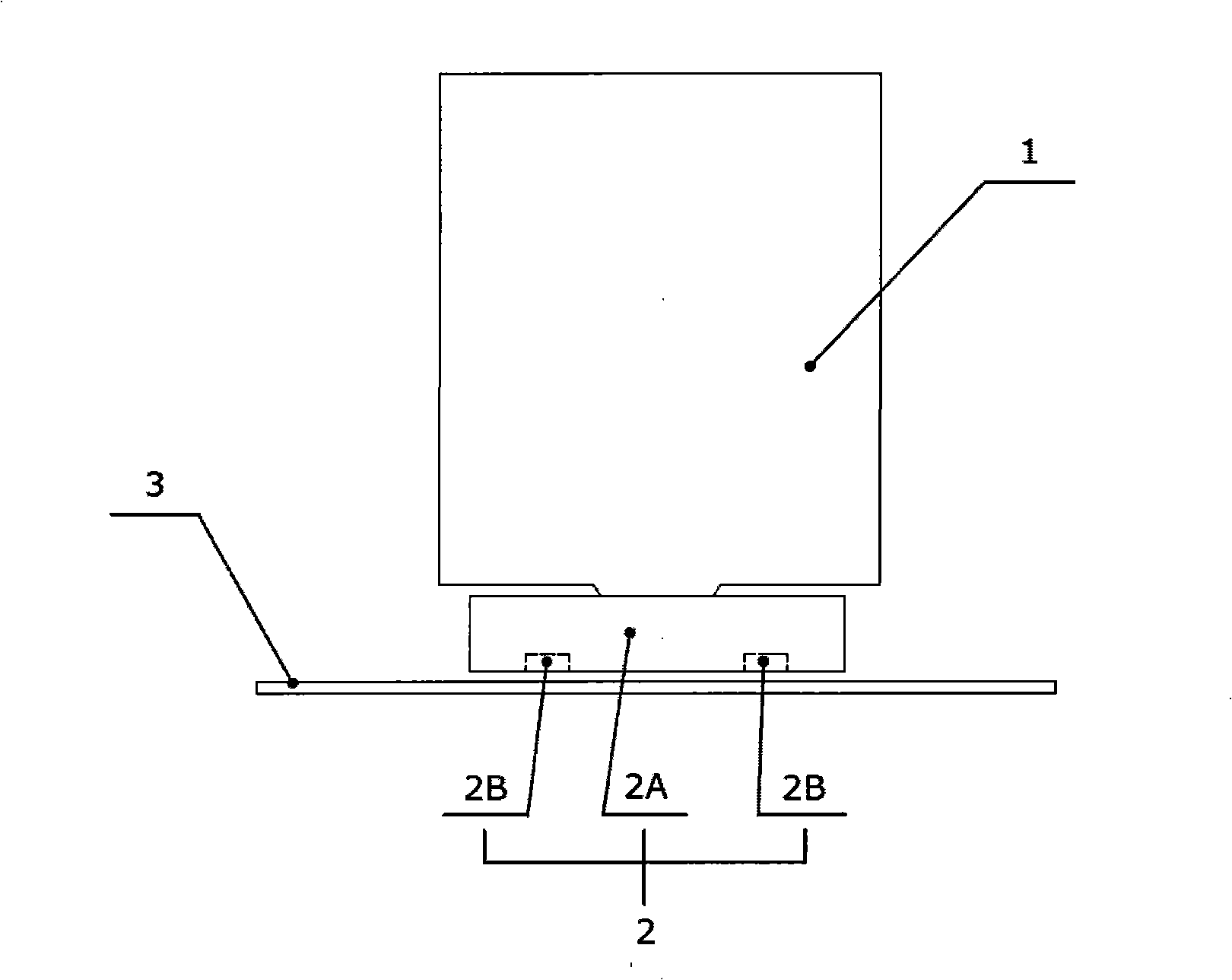

[0041] Such as figure 1 As shown, it shows the assembly of the immersion adaptive sealing control device and the projection lens group according to the embodiment of the present invention. The device can be applied in step-and-repeat or step-and-scan lithography equipment. During the exposure process, the light emitted from the light source (not shown in the figure) (such as: ArF or F2 excimer laser) passes through the aligned mask plate (not shown in the figure), the projection lens group 1 and the immersion liquid The lens-substrate gap field exposes the photoresist on the surface of the substrate 3 .

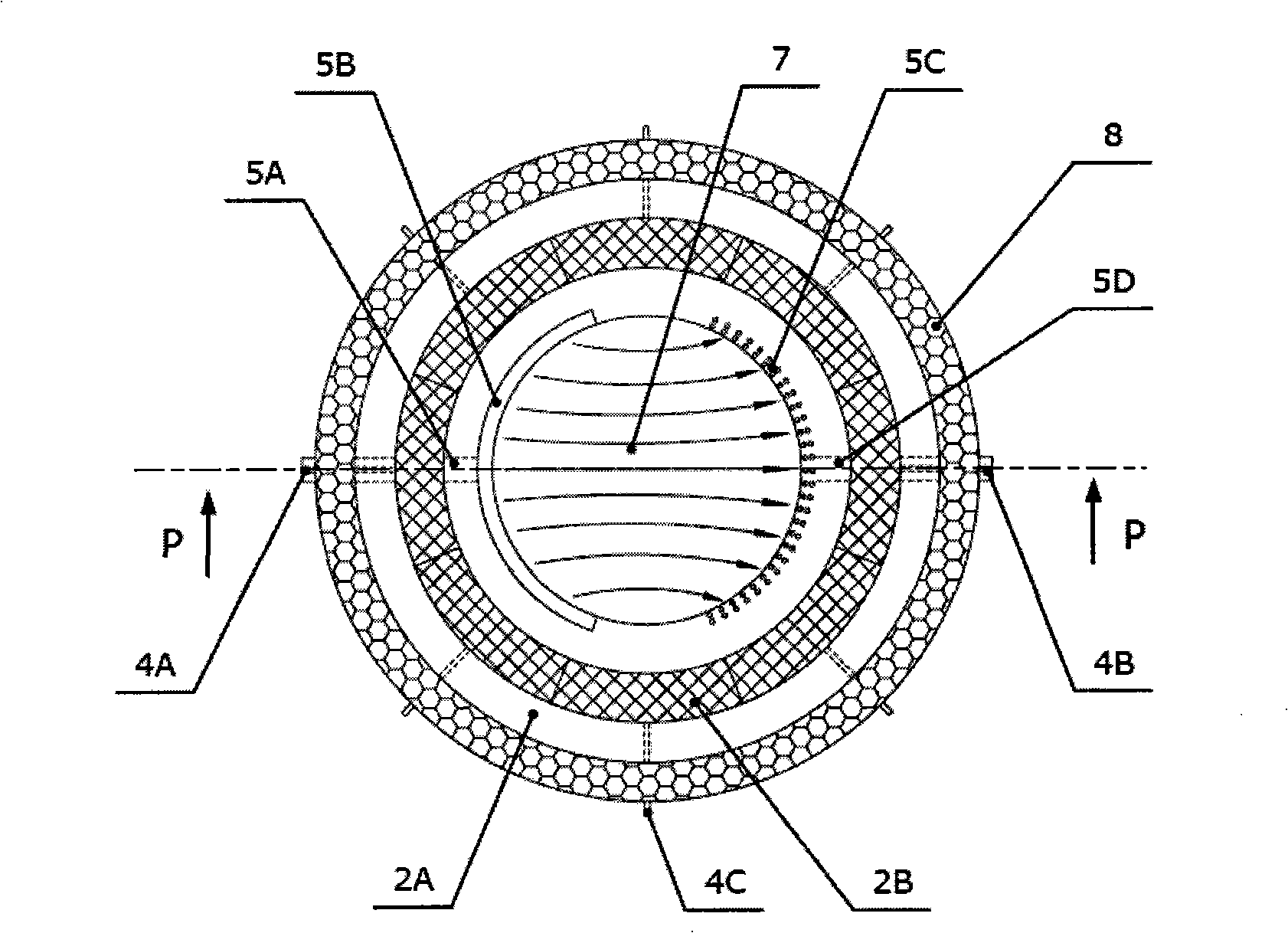

[0042] Such as Figure 1 to Figure 5 It schematically shows the immersion adaptive sealing control device of the embodiment of the present invention, which is composed of a sealing member 2A and an adaptive sealing member 2B, wherein:

[0043] 1) Sealing member 2A: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com