LED module

A technology of LED modules and sealing components, which is applied to the cooling/heating devices of lighting devices, lighting and heating equipment, electrical components, etc., which can solve the problems of insufficient reliability and low light efficiency of LED modules, and achieve reliable High performance, improve the light output rate, good sealing and waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

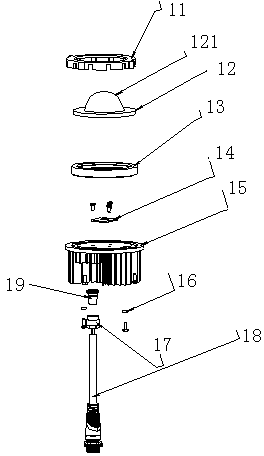

[0034] An LED module, comprising: a lens 12, a wafer-level packaged LED light source, and a substrate 14 (the wafer-level packaged LED light source is arranged on the substrate 14, and the wafer-level packaged LED light source is relatively small, and the number is not marked in the figure), and Radiator 15, substrate 14 is arranged on radiator 15, substrate 14 and radiator 15 can be directly connected or connected through media, lens 12 is provided with raised cavity 121, between the raised cavity 121 of lens 12 and radiator 15 A sealed and waterproof space for placing the LED light source is formed between them, and the substrate 14 is fixed to the heat sink 15 . A waterproof sealing ring 13 is arranged between the lens 12 and the radiator 15, which helps to improve the waterproof effect.

[0035] The LED light source can be welded on the substrate 14, and the substrate 14 includes one of a metal substrate and a ceramic substrate.

[0036] The LED light source can be a wafe...

Embodiment 2

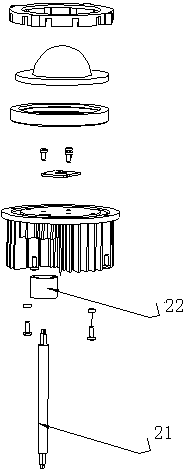

[0044] The only difference from Embodiment 1 is that the waterproof line 21 is connected and sealed through the back sealing ring 22 .

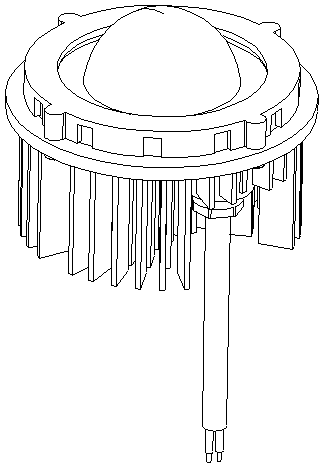

[0045] The LED module of the present invention is provided with only one lens, and only one convex cavity is provided on the lens. A plurality of wafer-level packaged LED light sources are placed in the raised cavity. In this way, the optical ratios such as color temperature and CRI are uniformly performed on the entire LED module to improve the optical performance of the entire LED module. Since this LED module can install multiple LED particles in a raised cavity, and fill the cavity with a refractive index matching liquid to improve light efficiency, the light efficiency of a single LED module can be greatly improved, and it can be used as a Applications such as car lights, greatly improving the application scenarios of LED modules.

Embodiment 3

[0047] see Figure 3A and Figure 3B , which is an example diagram of an LED module with two raised cavities. An LED module, comprising a heat sink 38, a lens 31, a substrate 34 provided with an LED luminous body, the LED luminous body is arranged in the lens 31, and the lens 31 is provided with at least one convex cavity (in this example, the lens 31 There are two raised cavities 311, 312), the LED illuminant includes at least one LED illuminant unit (in this example, the LED illuminant includes two LED illuminant units 331, 332), the raised cavity 311 , 312 are in one-to-one correspondence with the LED illuminant units 331, 332, and a sealed waterproof space for placing the LED illuminant units 331, 332 is formed between the raised cavities 311, 312 of the lens 31 and the radiator, and the substrate 34 is fixed on the radiator 38 , the LED illuminant units 331 and 332 may be composed of one or several wafer-level packaged LED light sources, and of course may also be compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com