Quick release component for pin-joint latch hook

A technology of pin connection and locking hook, which is applied in the direction of casing/cabinet/drawer components, etc., can solve the problems of difficult design angle, high surface stress of contact parts, connection failure of chassis and mounting frame, etc., and achieve light weight , low cost, and the effect of improving connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

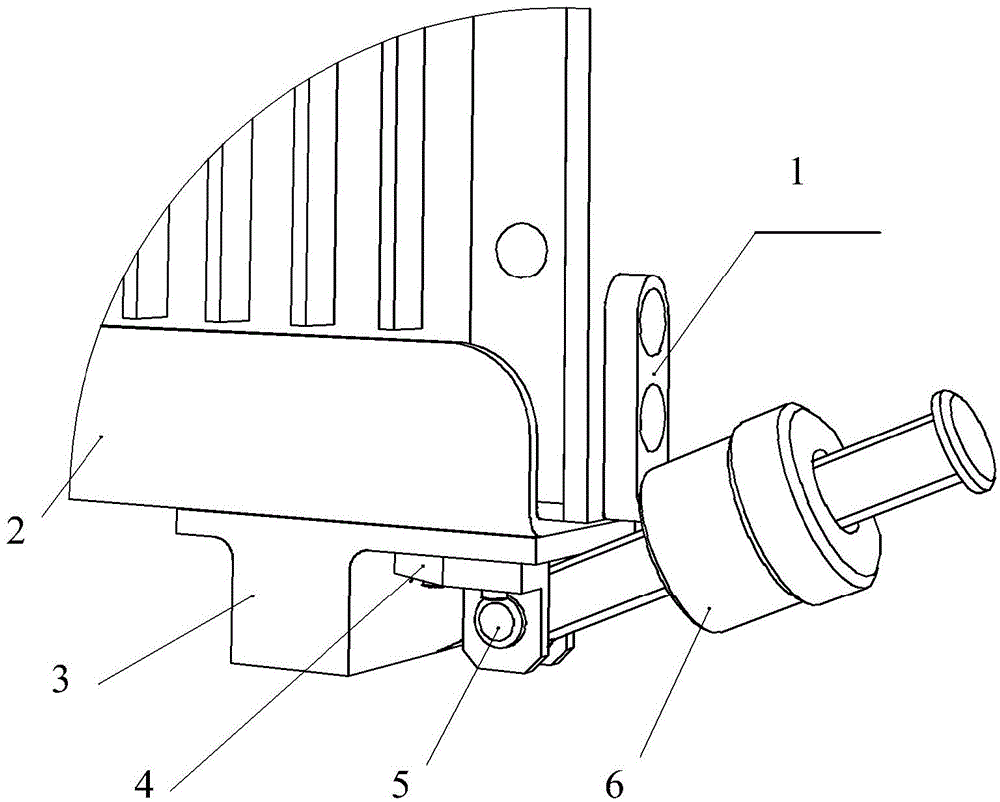

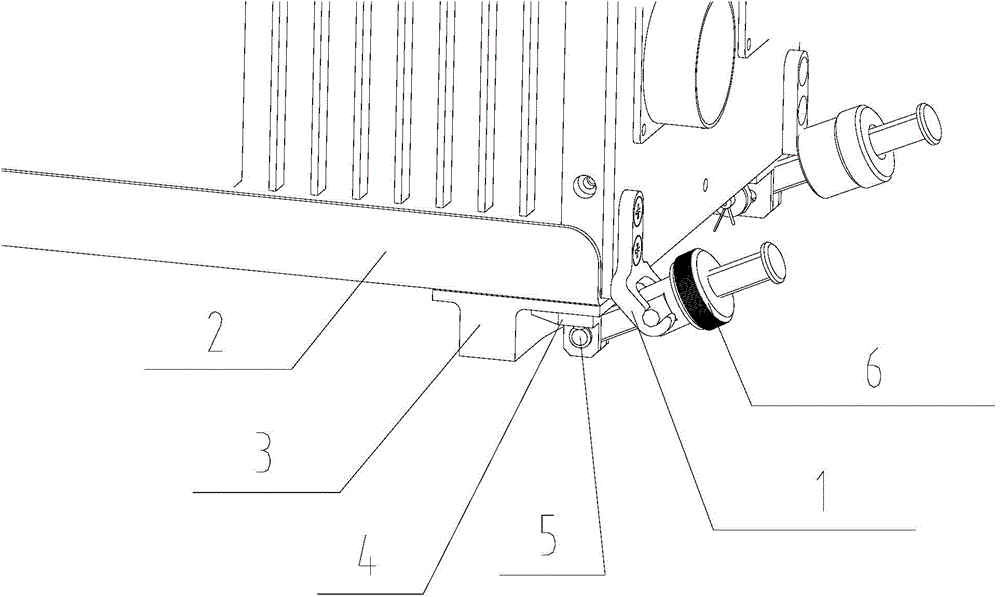

[0016] The present invention is described in detail in the following solutions to the accompanying drawings, as figure 2 Shown:

[0017] The chassis is connected to the connector through the guide. After the connection is completed, the chassis is placed on the guide. In order to prevent the chassis from sliding out of the guide due to vibration or to reduce reliability due to loose connection with the rear connector, the outer bottom of the guide A front base is installed, and a hinge is set on the front base for installing a locking device. The locking device is used to tighten the chassis, the connector and the guide through the front panel of the chassis. Therefore, the locking device needs to be applied to the chassis at the same time. Forces towards connectors and guides.

[0018] The pin-joint lock hook quick-release assembly is mainly composed of hinges, pins, pin-joint lock hooks, pin-joint front locking and other components. The pin-joint locking hook is fixedly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com