Linearly-reciprocating piston compressor

A linear reciprocating, piston-type technology, used in piston pumps, liquid variable-capacity machinery, mechanical equipment, etc., can solve problems such as increased friction loss, sluggishness, and roller 6 impact noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

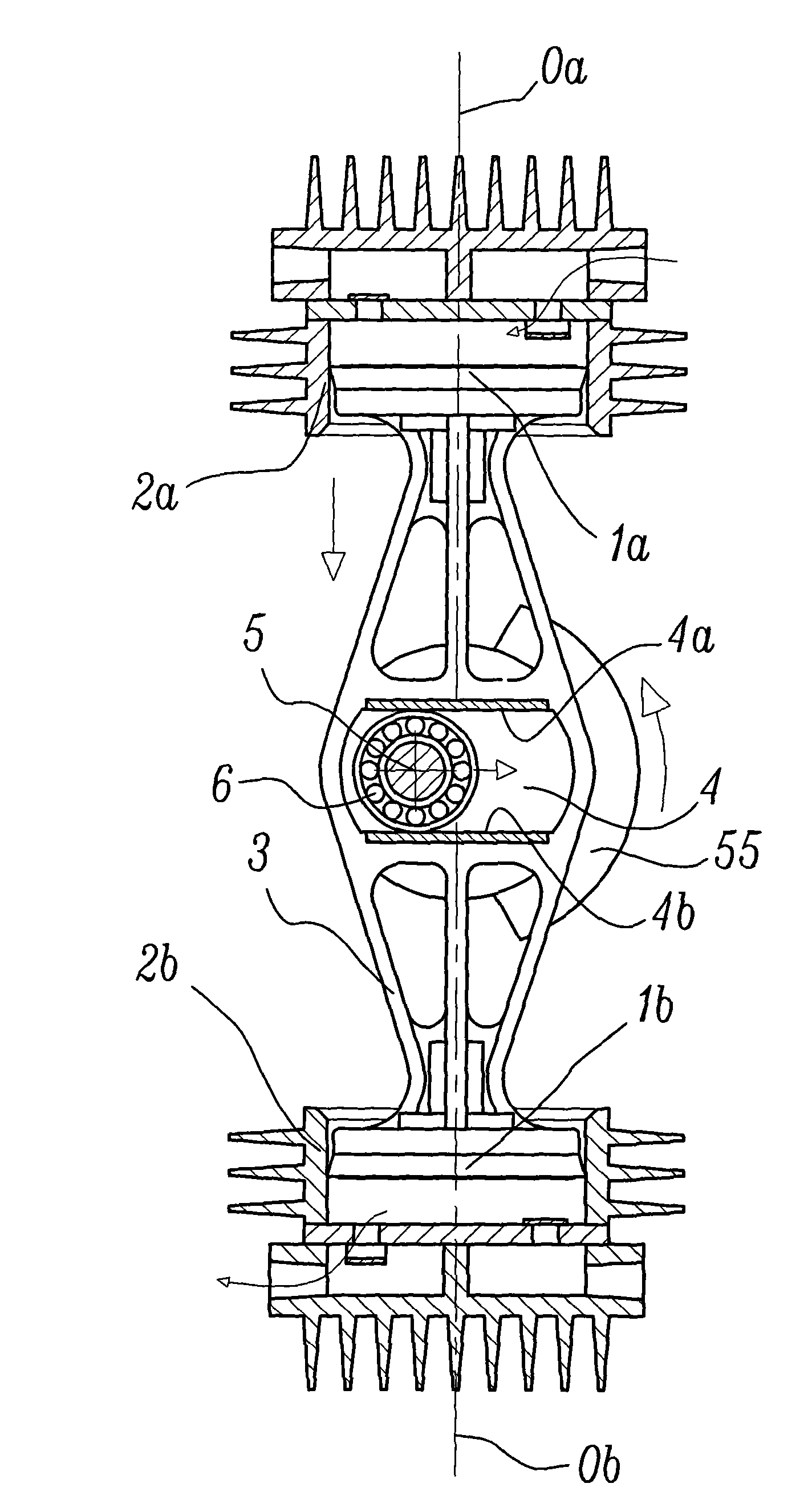

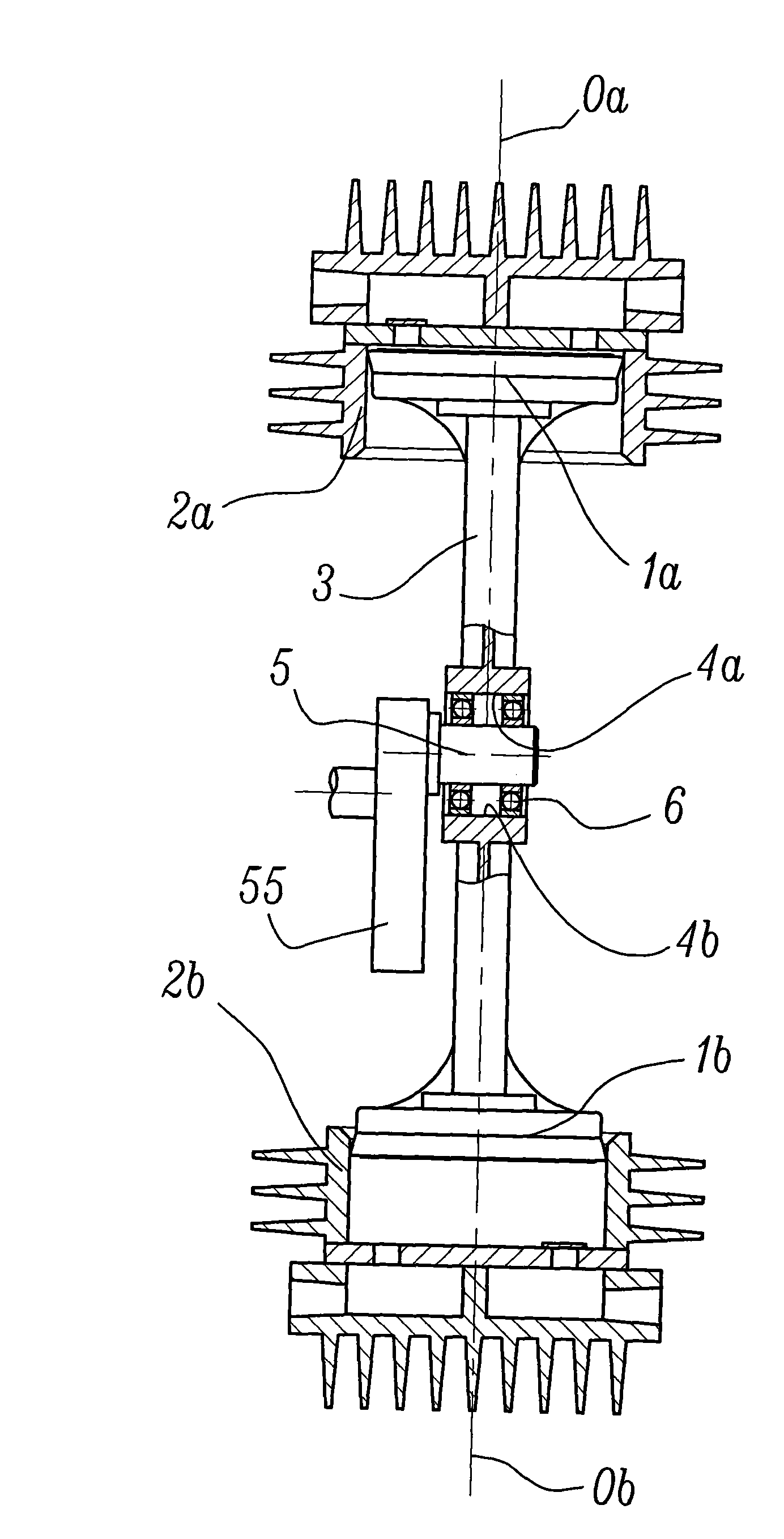

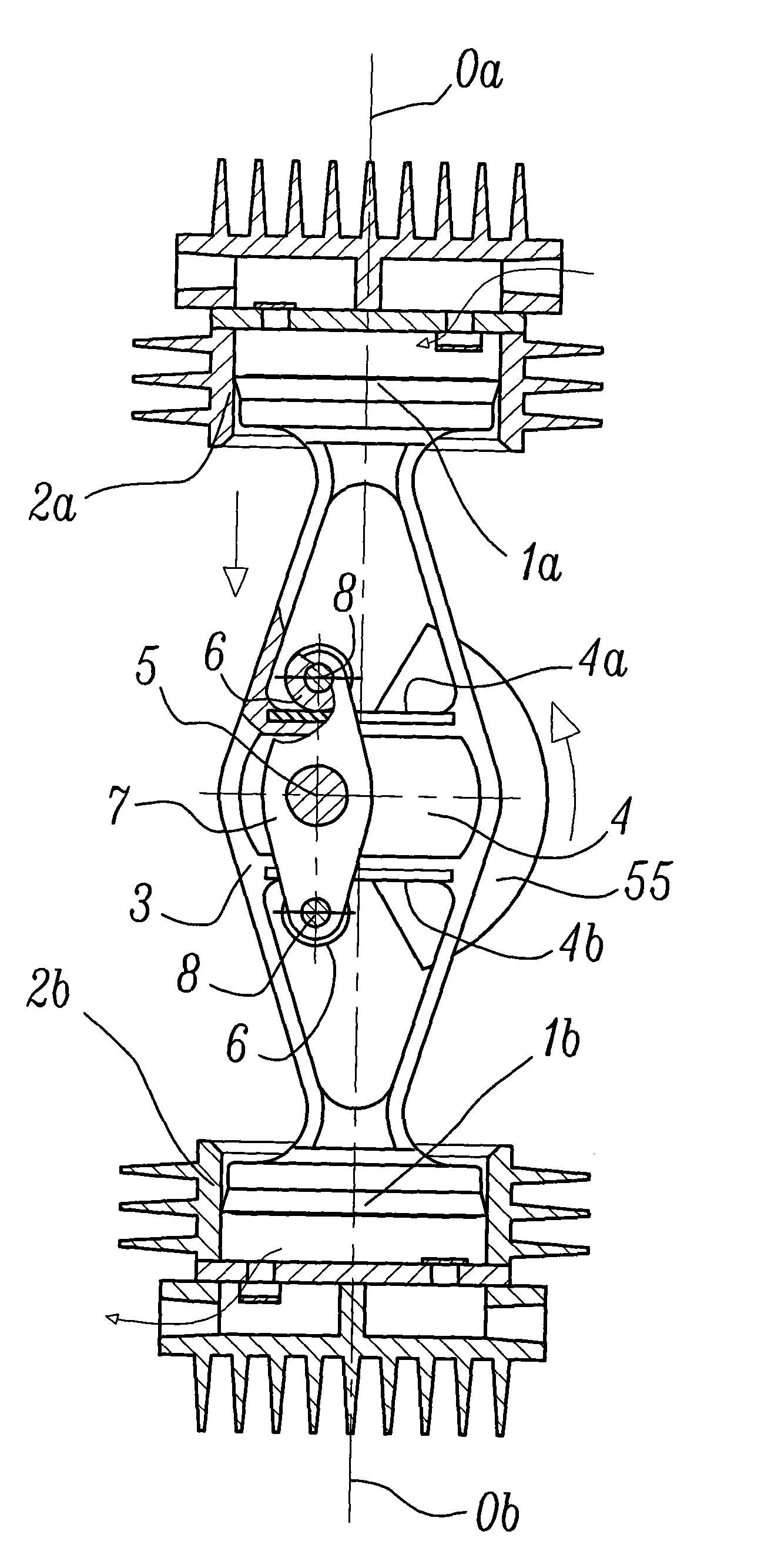

[0022] The present invention will be further described below with specific embodiment, see Figure 3-8 :

[0023] Figure 3 to Figure 8 A structural schematic diagram of a linear reciprocating piston compressor of the present invention is given, and the labels, names and functions of the parts in the figure are inherited figure 1 and figure 2 Shown is an existing linear reciprocating piston compressor. The linear reciprocating piston compressor of the present invention comprises: a motor, a crank driven by the motor and a crank pin 5 connected to the crank, two oppositely distributed pistons 1a, 1b and cylinders 2a, 2b, and a connecting rod 3, the The axes 0a, 0b of the cylinders 2a, 2b are arranged parallel to each other or coaxially (there is a certain manufacturing error and assembly error allowed), and the pistons 1a, 1b are arranged in the cylinders 2a, 2b and slidably fit with them. The two ends of the rod 3 are respectively connected with the two pistons 1a, 1b, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com