Coaxiality detection method

A detection method and coaxiality technology, which is applied in the detection field, can solve the problems of low measurement accuracy of the coaxiality detection method and low precision of the coaxiality error value, so as to ensure accuracy, high precision, and overcome cumulative errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

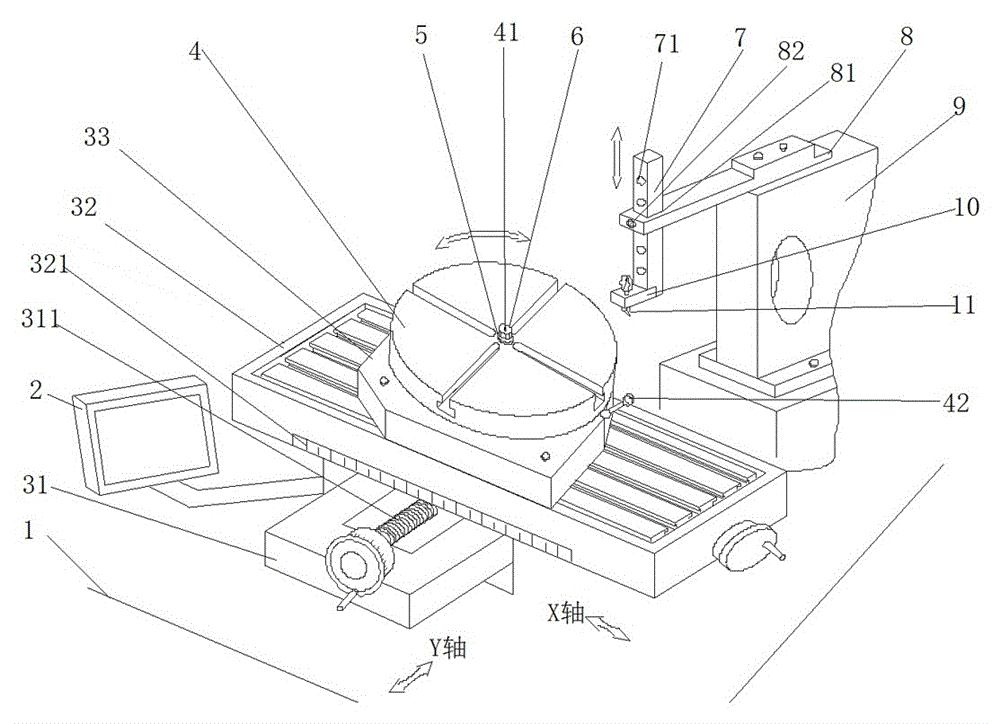

[0041] This embodiment provides a coaxiality detection method, comprising the following steps:

[0042] S1: Set one end hole of the standard workpiece on the rotating shaft 41, and make the probe of the measuring gauge 11 and the inner wall of the other end hole of the standard workpiece measure the circle P 0 Measuring point contact on a certain circle;

[0043] Observe the pointer pointing of measuring table 11, if the pointer of measuring table 11 points to the zero position, it means that rotating shaft 41 is parallel to the axis of measuring table 11 in the vertical direction. At this time, take off the standard workpiece and complete the calibration of rotating shaft 41; The pointer of measuring table 11 points to deviate from the zero position, then adjust the horizontal and / or vertical position of rotating shaft 41 by adjusting device, take off standard workpiece when the pointer of measuring table 11 points to zero position, complete the correction of rotating shaft 4...

Embodiment 2

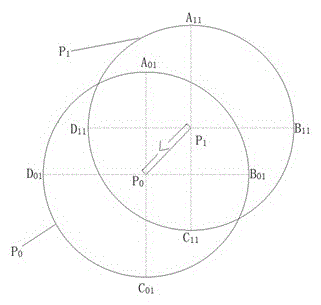

[0064] This embodiment provides a coaxiality detection method, the difference from Embodiment 1 is: for the measurement circle P of the standard workpiece 0 , and the measuring circle P of the workpiece to be detected 1 The measurement points above are all four measurement points, two of which are two ends distributed on the diameter of the measurement circle in the horizontal direction, and the other two measurement points are two ends distributed on the diameter of the measurement circle in the vertical direction.

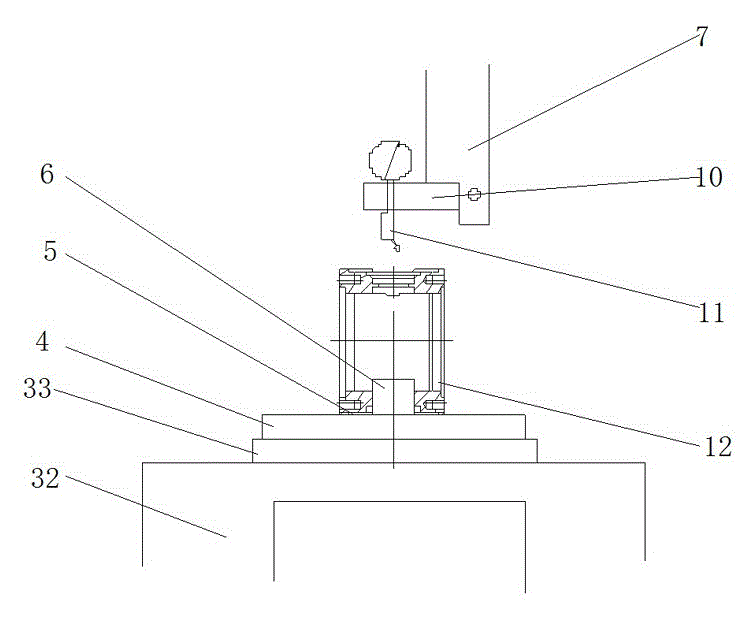

[0065] For example, when measuring the coaxiality error of the valve stem holes at both ends of the valve body 12, the assembly diagram of the valve body 12 installed on the inner hole expander 6 is as follows: figure 2 shown. First, the axis of the rotating shaft 41 of the standard workpiece in the vertical direction is calibrated, as image 3 As shown in the standard workpiece measurement circle P 0 The four measurement points on the same circumference of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com