A high-frequency eddy current non-ferrous metal separator

A non-ferrous metal, sorting machine technology, applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve problems such as processing and utilization difficulties, waste of materials, environment, sorting, etc., to achieve compact and reasonable economic benefits and compact structure. Reasonable, stable and low-impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

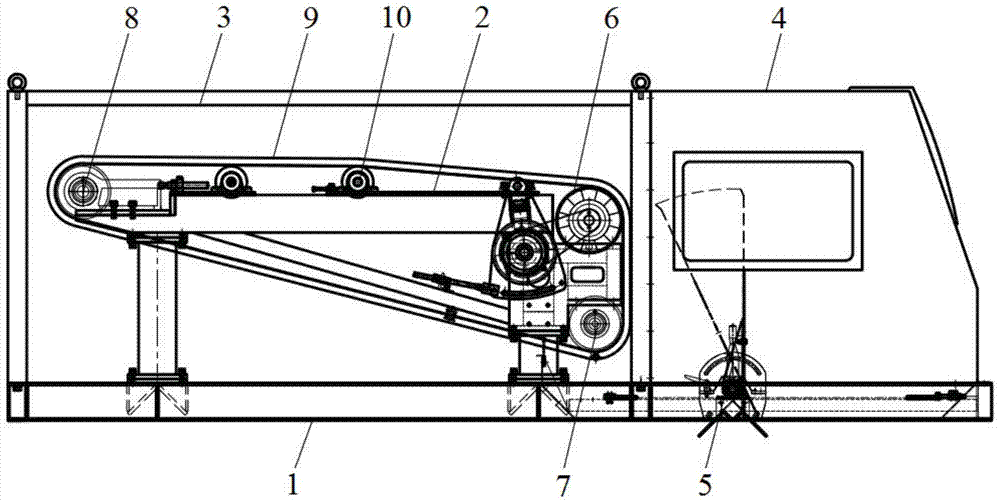

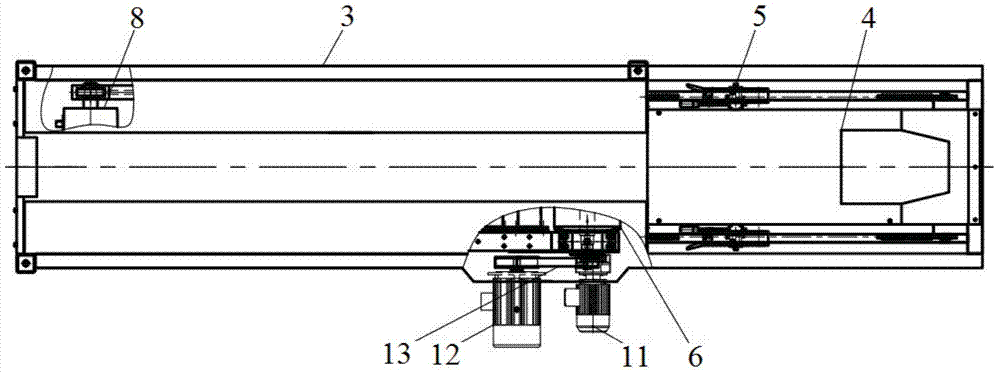

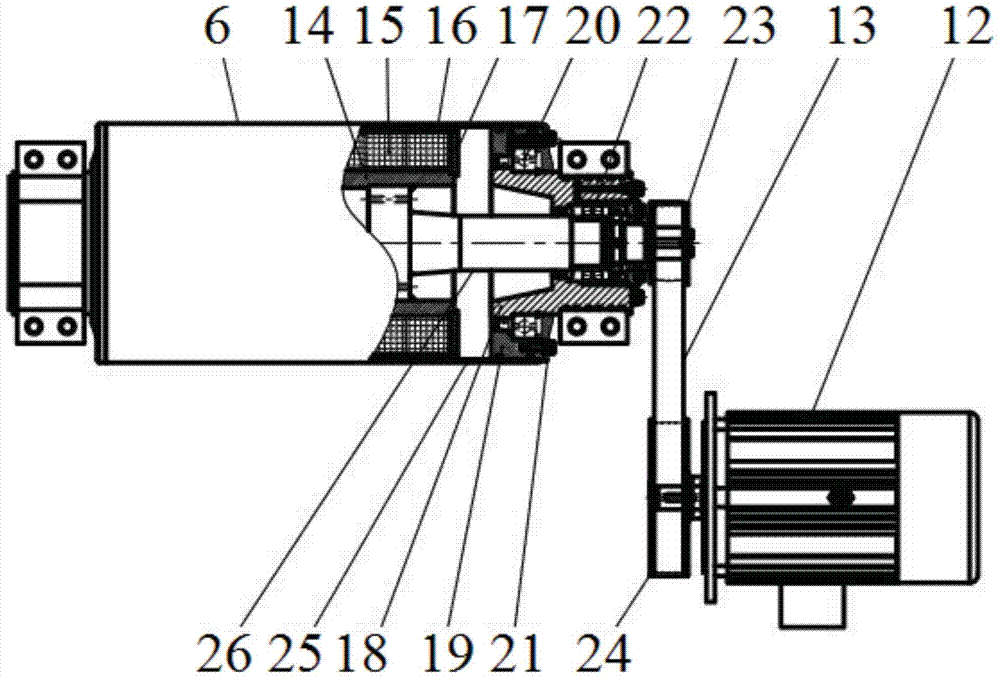

[0018] Such as figure 1 , figure 2 with image 3 As shown, a high-frequency eddy current non-ferrous metal sorting machine includes a base 1, a protective cover 3, and a material distributing cover 4; the base 1, the protective cover 3 and the material distributing cover 4 together form a fully enclosed box The inside of the protective cover 3 and the base 1 is provided with a frame 2; the inside of the material dividing cover 4 and the base 1 is provided with a material dividing plate 5; the right end of the frame 2 A magnetic roller 6 is fixed; the lower right end of the frame 2 is fixed with a drive roller 7; the left end of the frame 2 is fixed with a tension roller 8; the magnetic roller 6, the drive roller 7 and the tension The roller 8 is connected in series by the feeding belt 9 to form a triangular structure; the magnetic roller 6 is driven by the magnetic roller drive motor 12; the drive roller 7 is driven by the belt drive motor 11; the base 1 under the feed cover 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com