A positioning welding device and welding method for range hood fan casing

A technology of positioning welding and range hood, applied in welding equipment, welding equipment, auxiliary devices, etc., can solve the problems of easy deviation of two sheets, affecting the quality of fan casing, shortening the service life of fan casing, etc., to achieve overall structural strength Firmness, compact and reasonable structure design, and the effect of avoiding deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

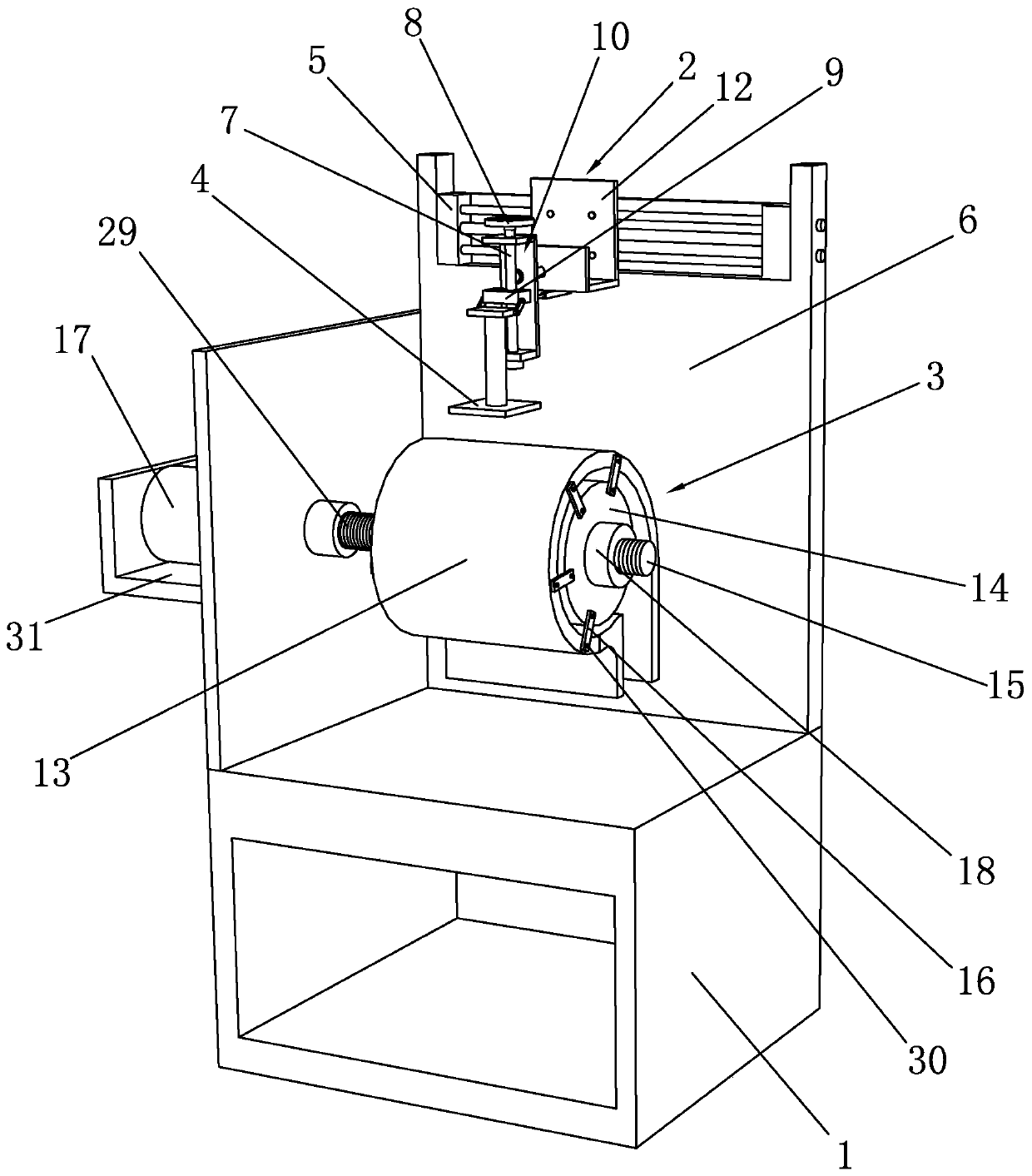

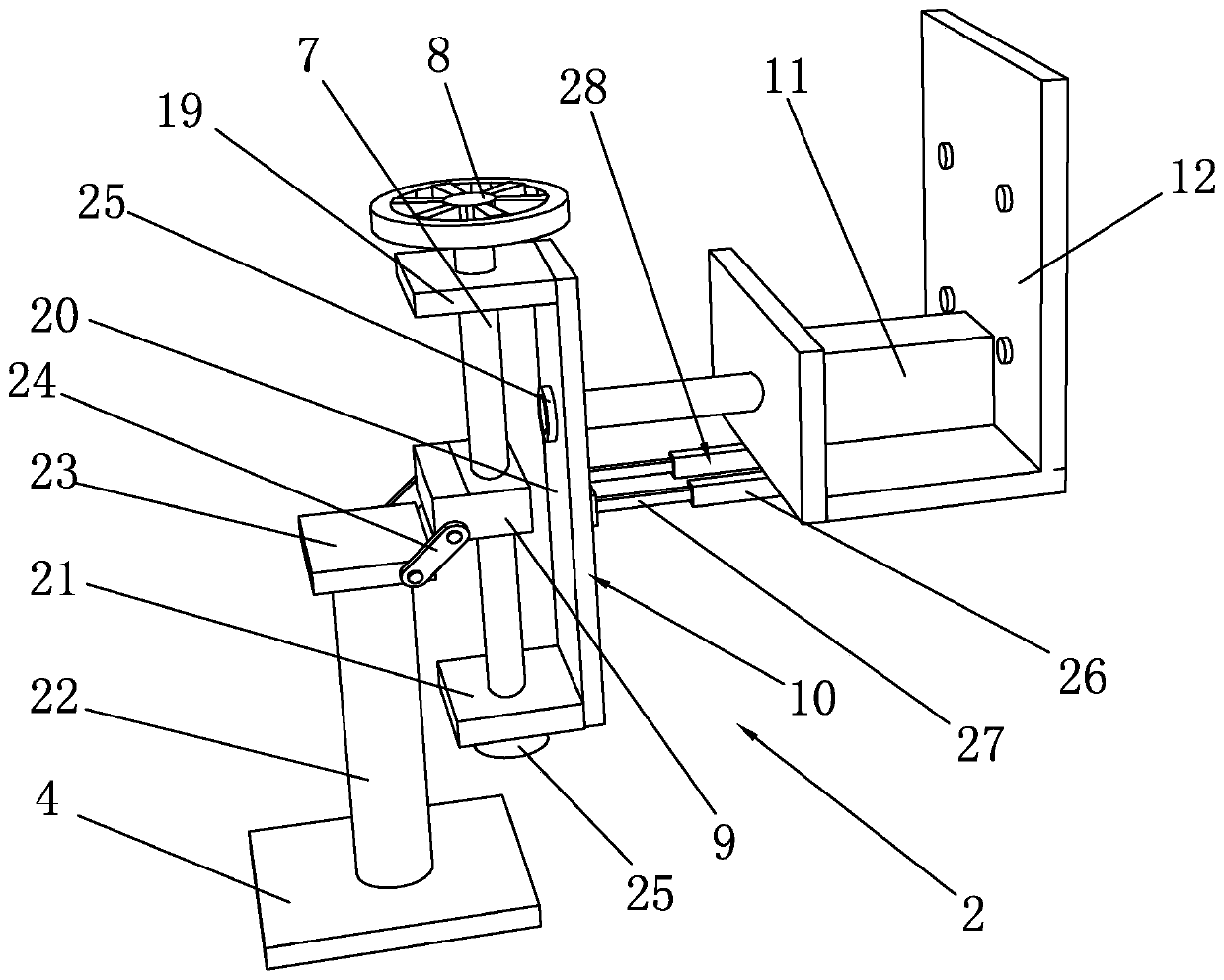

[0030] Such as figure 1 and figure 2As shown, it is a positioning welding device for the range hood fan casing of the present invention, including a support table 1, a clamping assembly 2 and a mold assembly 3, and the clamping assembly 2 includes a clamping block 4, an X-direction adjustment mechanism, a Y The adjustment mechanism in the X direction and the Z direction adjustment mechanism, the X direction adjustment mechanism includes a rodless cylinder 5, the rodless cylinder 5 is fixedly connected with the support platform 1 through the tailgate 6, the rodless cylinder 5 is fixed on the tailgate 6, and the Y direction adjustment The mechanism includes an adjusting screw 7 and an adjusting handwheel 8, the adjusting handwheel 8 is located at the top of the adjusting screw 7, the adjusting screw 7 is provided with a slider 9, the clamping block 4 and the sliding block 9 are hinged and fixed, and the clamping block 4 The top surface is provided with connecting rod 22, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com