Horizontal type submersible motor

A submersible and horizontal technology, applied in the field of horizontal submersible motors, can solve the problems of uneven stator and rotor air gaps, deflection bending deformation, large motor vibration, etc., to increase the horizontal use range and reduce bending deformation. , the effect of taking a short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

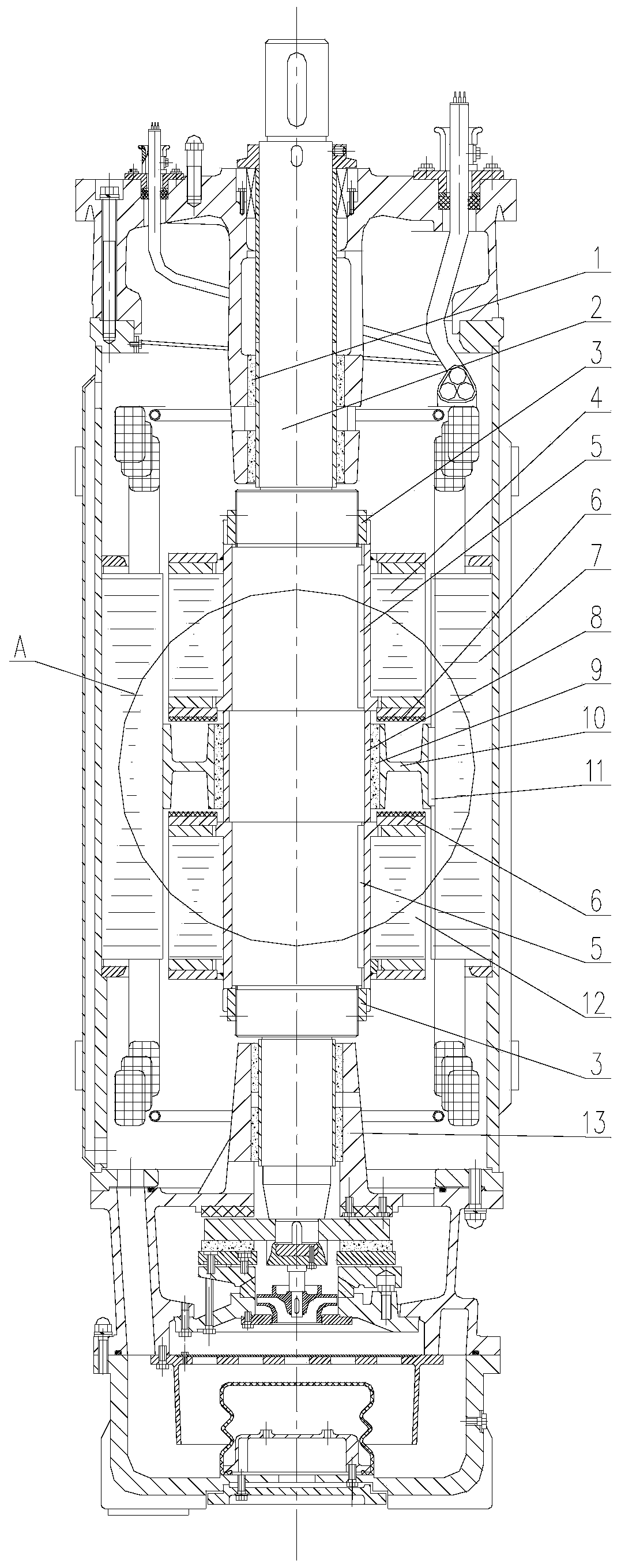

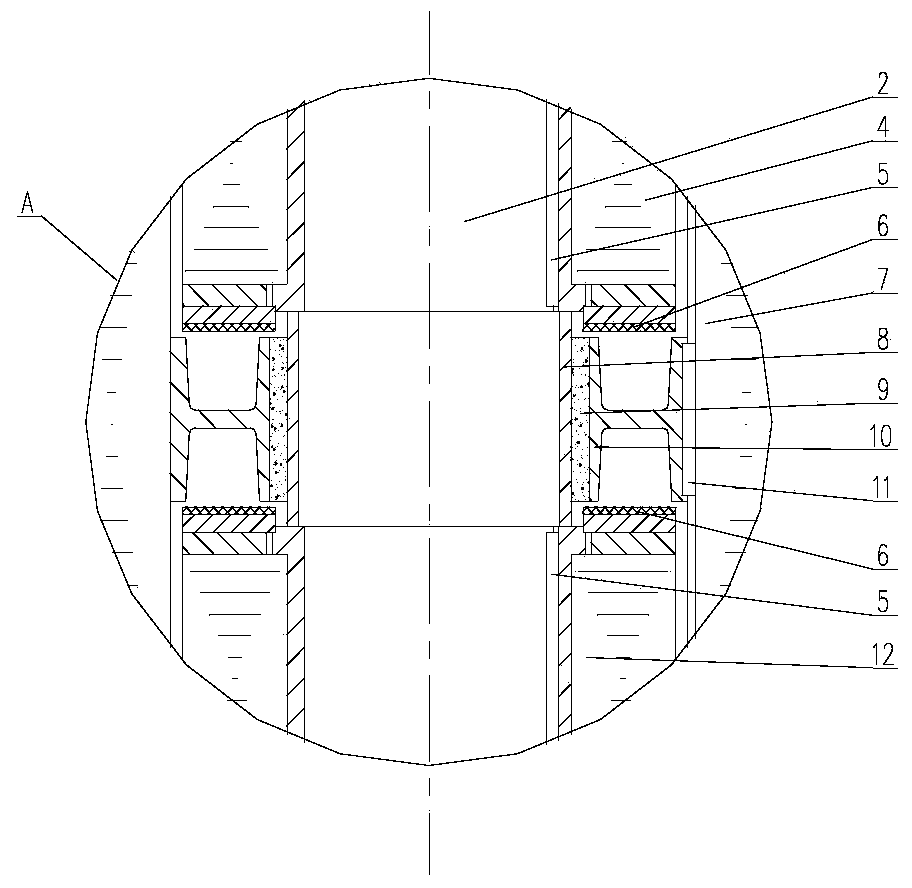

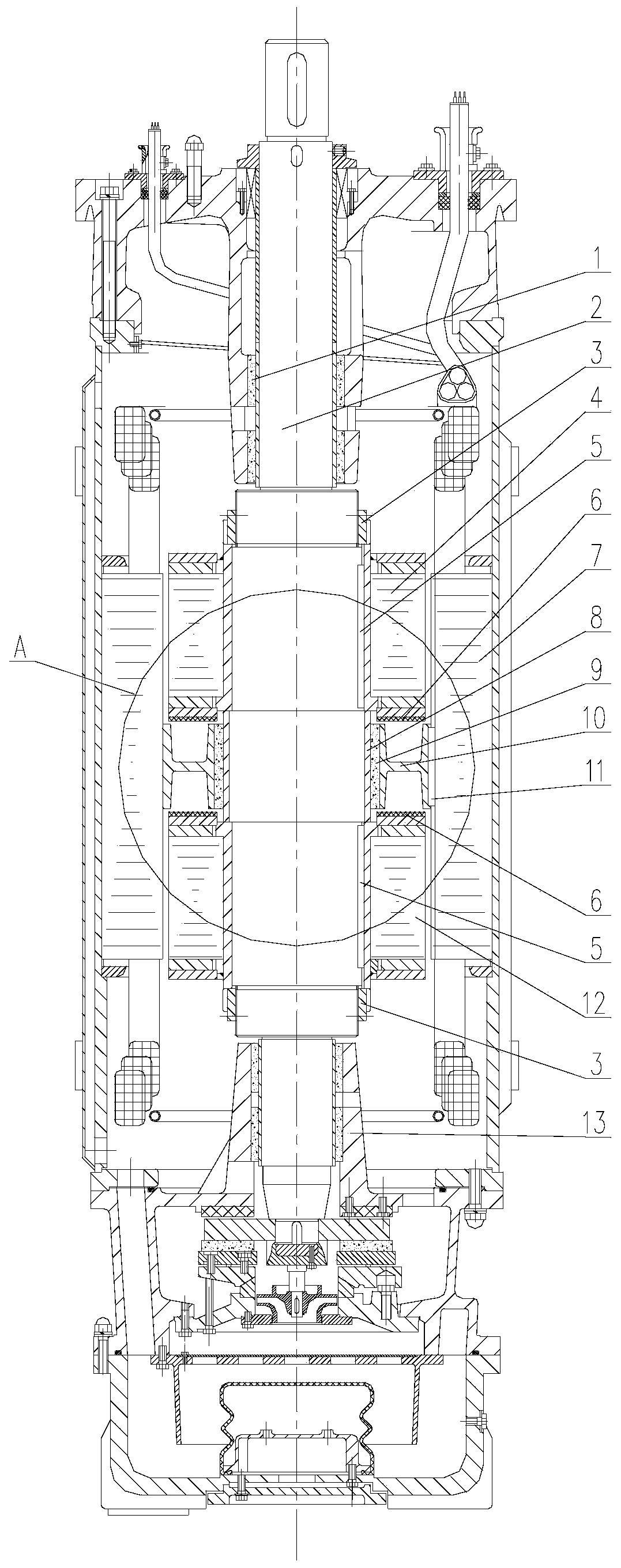

[0018] like figure 1 and figure 2 As shown, the technical scheme of the present invention is:

[0019] A horizontal submersible motor mainly includes: an upper guide bearing 1, a shaft 2, a lock nut 3, an upper rotor 4, a rotor key 5, a thrust piece 6, a stator 7, an intermediate bushing 8, an intermediate bearing bush 9, and an intermediate bearing The seat 10, the middle bearing key 11, the lower rotor 12 and the lower guide bearing 13; the part of the shaft 2 between the upper guide bearing 1 and the lower guide bearing 13 is a stepped circular truncated part; the outer surface structure of the shaft 2 is large The diameter of the first stepped circular table, the two ends of the extension axis have a second stepped circular table with a smaller dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com