Rapid electric arc fused deposition and laser shock forging combined part forming method and device

一种激光冲击、激光装置的技术,应用在零件与模具锻打制造领域,能够解决残余应力叠加效应明显、零件易开裂和变形等问题,达到控制宏观变形和开裂问题、细化晶粒、保证成形质量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

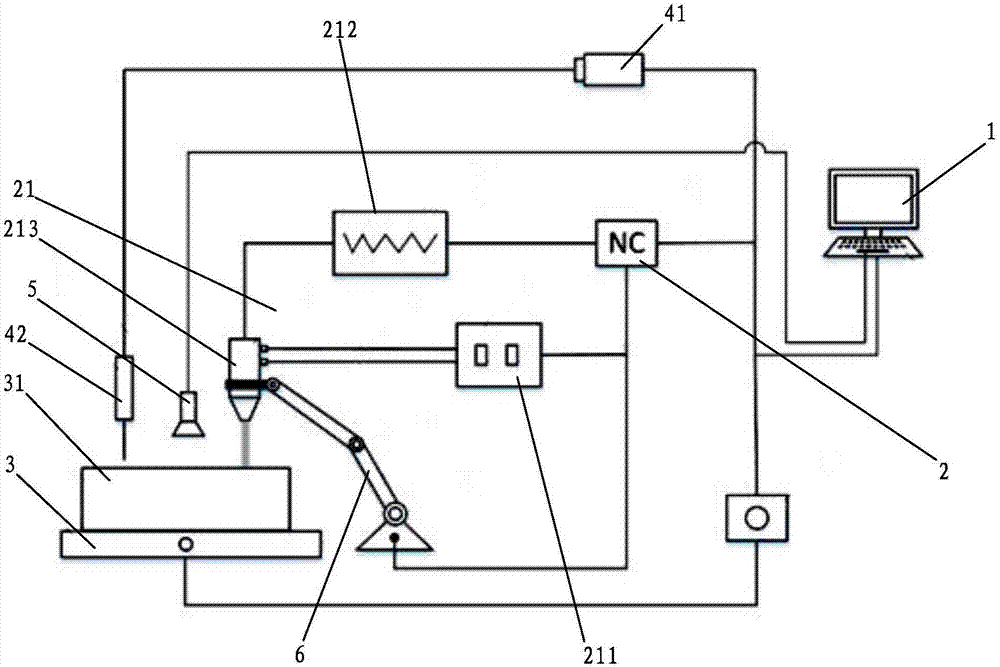

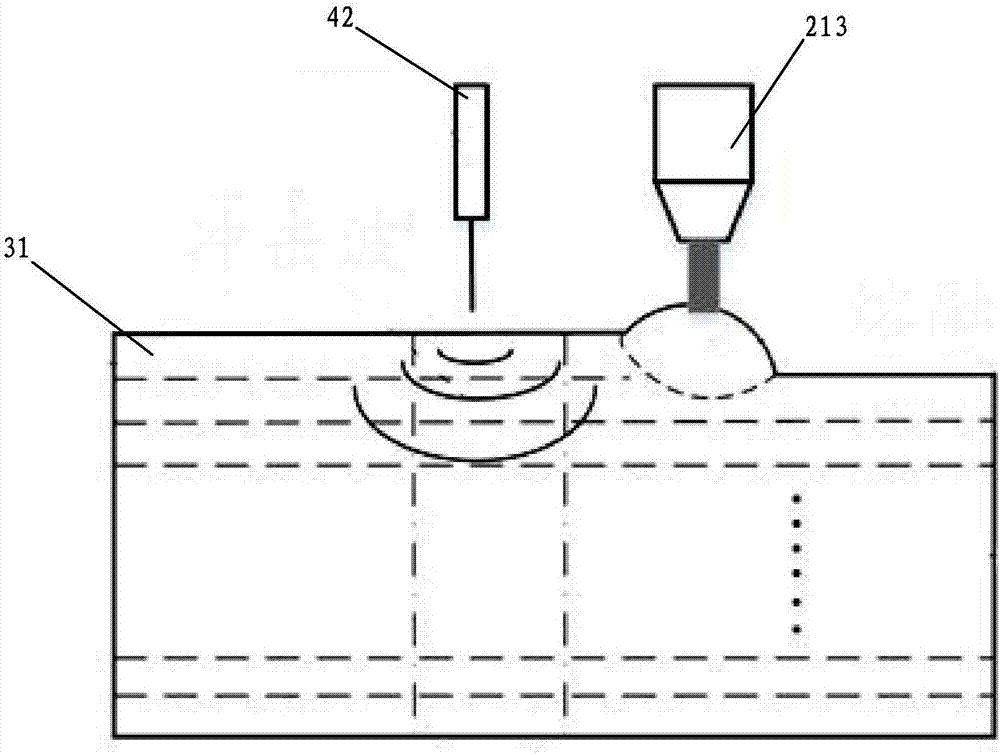

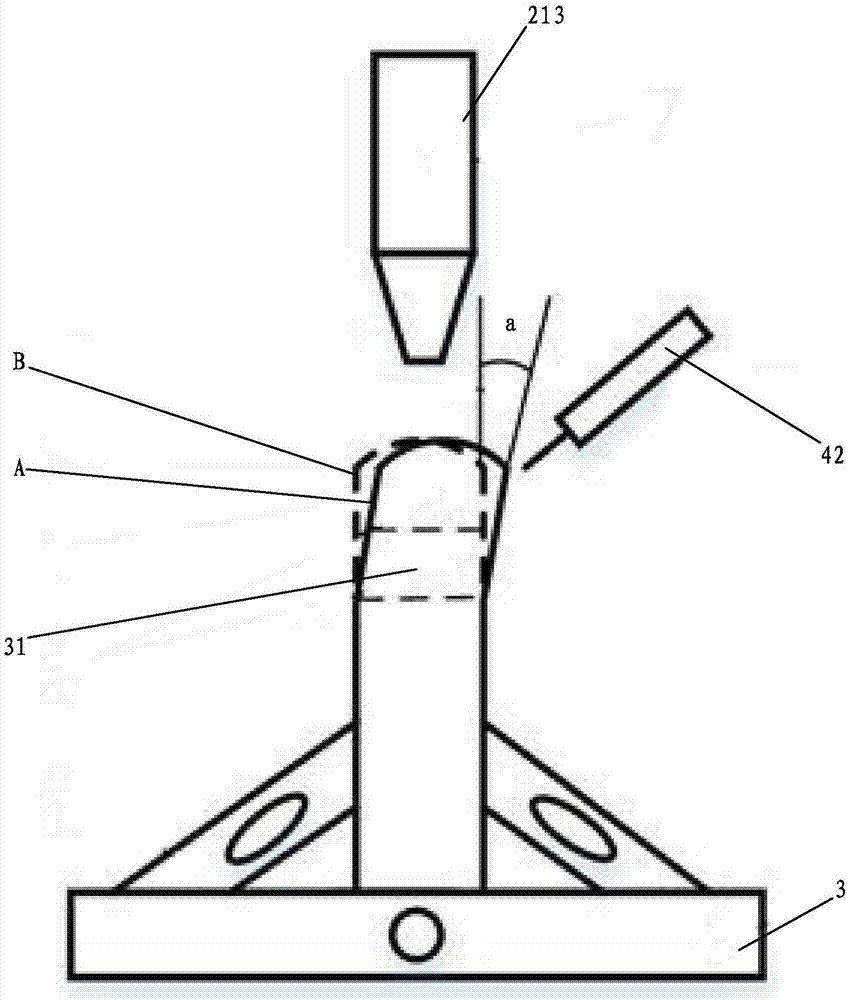

[0031] refer to figure 1 with figure 2 , the present embodiment relates to a method for arc deposition and laser shock forging composite rapid prototyping parts, comprising the following steps:

[0032] 1) Draw the 3D model of the part, import the model into the simulation system of computer 1; divide the preformed part model into one or several simple forming units through the simulation system, and determine the forming sequence of the forming units; Layered slice processing in stacking direction, processing data according to layered slices and generating NC codes for processing each layer; for example figure 1 As shown in , draw the 3D model of the part in the simulation software in computer 1, or use other 3D drawing software (such as SolidWorks, UG, etc.) to draw the 3D model of the part, and import it into the simulation software, then use the simulation software to convert the The forming part model is divided into one or several simple forming units, the forming seq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com