Modified rubber particle impact-resistant abrasion-resistant ultrahigh-toughness concrete and preparation method thereof

A modified rubber and ultra-high toughness technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problem of poor impact toughness and abrasion resistance, strong destructive force, and interface bonding ability Poor problems, to achieve the effect of improving impact toughness and abrasion resistance, improving impact toughness, and good working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

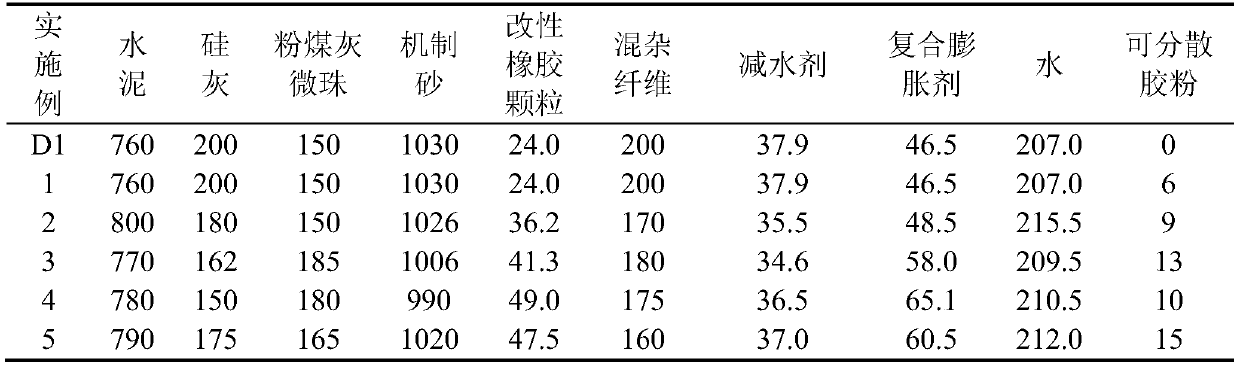

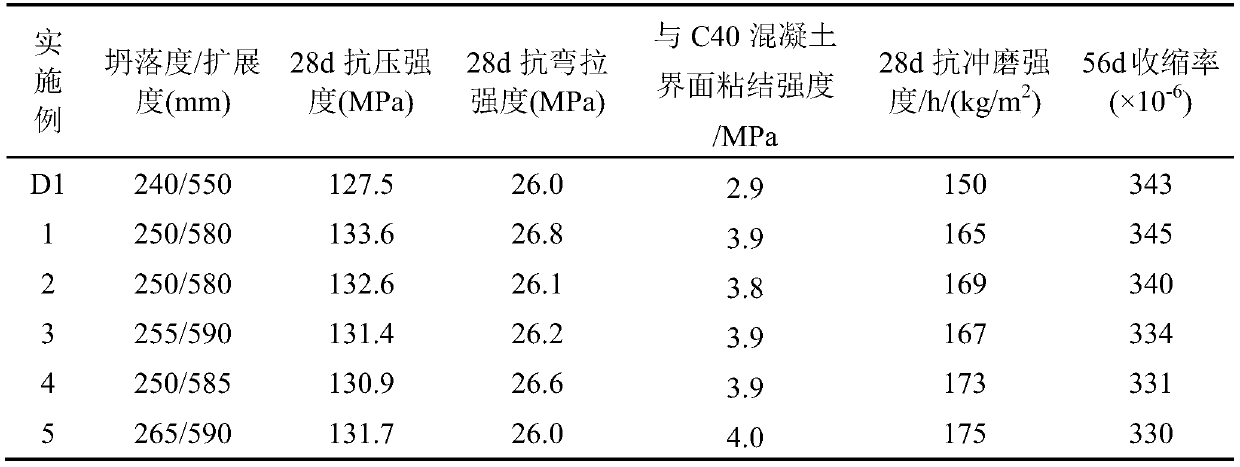

[0054] The modified rubber particle abrasion-resistant ultra-high toughness concrete described in Examples 1 to 5 uses dispersible rubber powder as an interface enhancer, and its preparation method includes the following steps:

[0055] 1) Take each raw material respectively by the proportioning described in Table 1;

[0056] 2) Add the weighed machine-made sand, cement, silica fume and fly ash microbeads into the concrete mixer for pre-mixing for 3 minutes, pour in the rubber particles and stir for 2 minutes, pour in water and water reducing agent and stir for 4 minutes, then add the composite expansion agent and stir for 2 minutes , then evenly add mixed fibers and continue to stir for 3 minutes; add dispersible rubber powder and stir for 1 minute, and finally carry out mold loading, vibration and molding, and cover the surface with an impermeable film, and remove the mold after 1 day for standard maintenance to obtain the modified product. Rubber particles anti-abrasion ult...

Embodiment 6~10

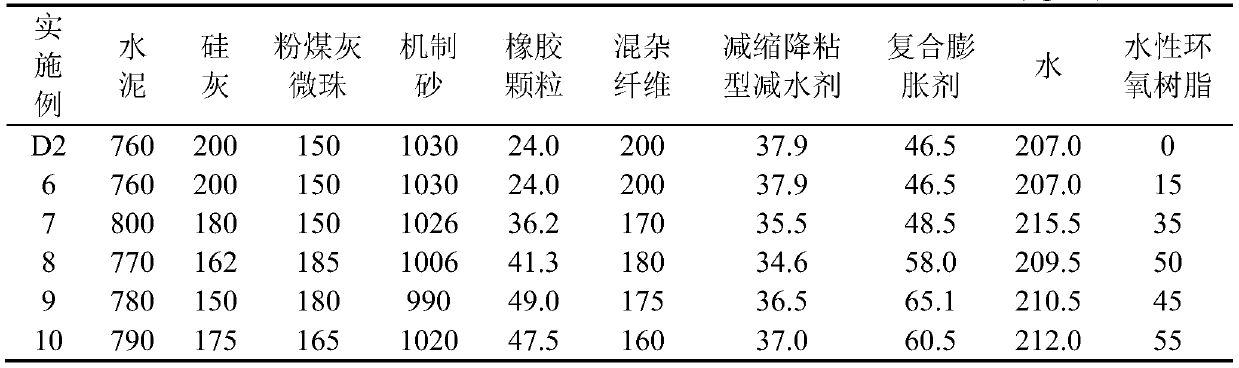

[0064] The modified rubber particle abrasion-resistant ultra-high-performance concrete described in Examples 6-10 uses water-based epoxy resin as an interface enhancer, and its preparation method includes the following steps:

[0065] 1) take each raw material respectively by the proportioning condition described in table 3;

[0066]2) Add machine-made sand, cement, silica fume and fly ash microbeads to the concrete mixer for pre-mixing for 3 minutes, pour in rubber particles and stir for 2 minutes, pour in water and water reducing agent and stir for 4 minutes, then add composite expansion agent and stir for 2 minutes, and then mix evenly Add mixed fibers and continue to stir for 3 minutes; add water-based epoxy resin and stir for 3 minutes, and finally carry out mold loading, vibration, and molding, and cover the surface with an impermeable film. After 1 day, the mold is removed for standard maintenance, and the modified rubber particles are resistant Scrubbing ultra-high per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com