Method for improving high-temperature oxidation resistance of Nb-Si-based multicomponent alloy

A high-temperature oxidation resistance and alloy technology, which is used in the field of improving the high-temperature oxidation resistance of Nb-Si-based multi-component alloys by using laser surface remelting technology, and improving the high-temperature oxidation resistance of ultra-high temperature alloys, can solve the problem of Nb-Si-based multi-component alloys. problems such as poor oxidative properties, to achieve the effects of simple preparation, improved short-term high-temperature oxidation resistance, and simple and practical methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

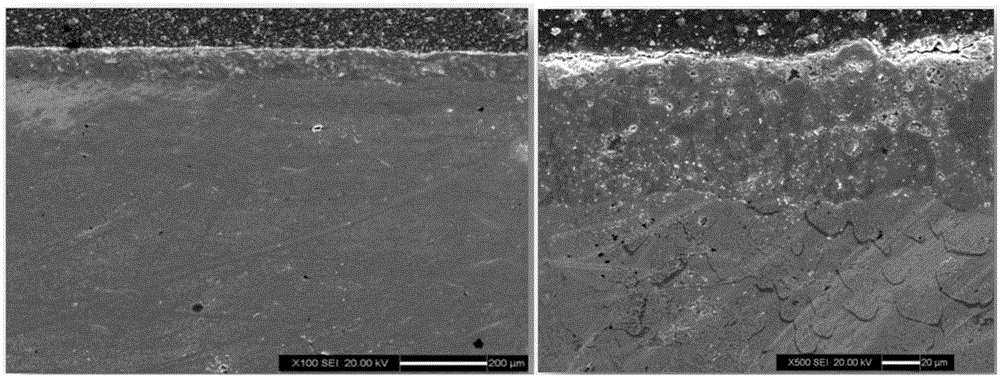

Embodiment 1

[0035] Use laser surface remelting technology to improve the high temperature oxidation resistance of Nb-Si based multi-component alloys. The laser melting system used mainly includes: Nd-YAG laser, computer system and argon atmosphere protection device. The steps are as follows:

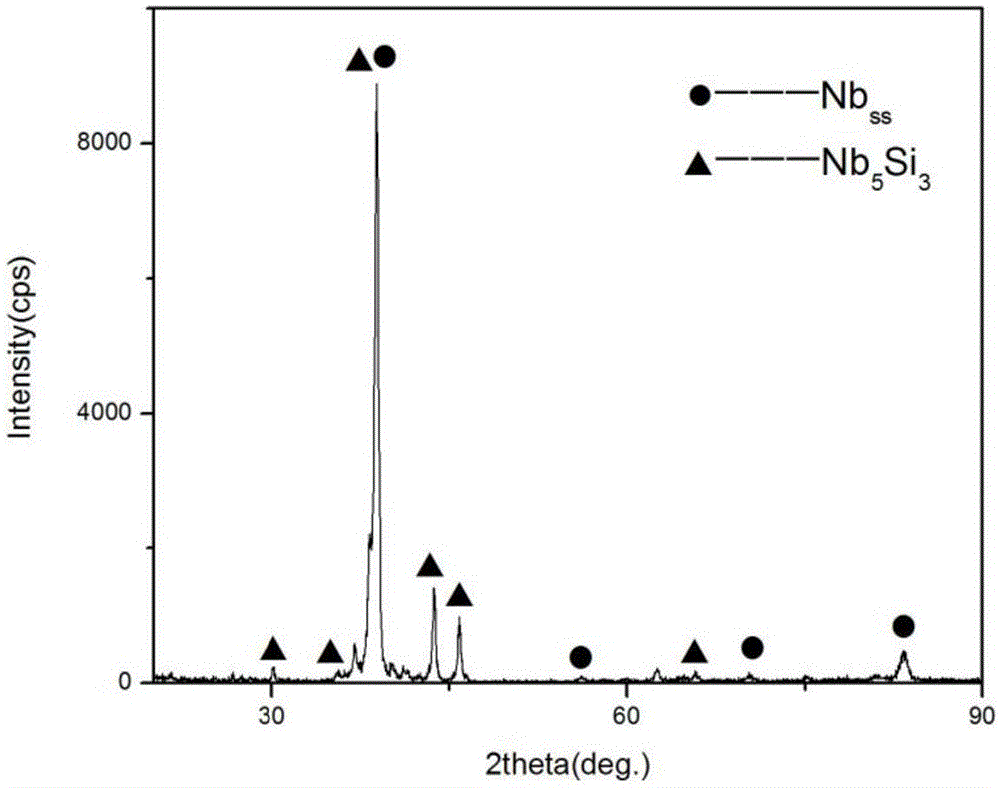

[0036] 1. Using Nb, Si, Ti, Cr, Al, Hf as synthetic raw materials, using vacuum non-consumable arc melting technology to obtain Nb-16Si-24Ti-2Cr-2Al-2Hf alloy master ingot, using wire cutting to cut samples, Polish the surface of the sample, clean it and dry it for later use;

[0037] 2. Fix the Nb-16Si-24Ti-2Cr-2Al-2Hf alloy sample on the workbench, first evacuate the sealed forming cavity into a vacuum state, and then fill it with high-purity argon (99.99%) for protection;

[0038] 3. The laser beam performs preheating scanning on the surface of the Nb-16Si-24Ti-2Cr-2Al-2Hf alloy sample according to the preset scanning path and parameters. The specific preheating parameters: laser power 300W, scan...

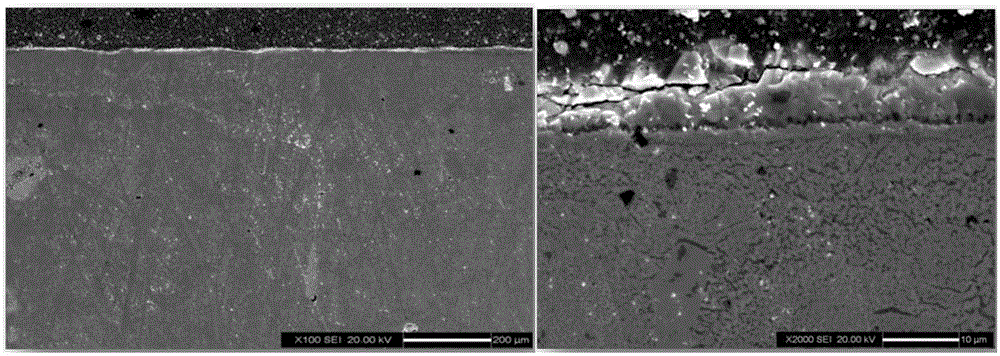

Embodiment 2

[0046] Use laser surface remelting technology to improve high temperature oxidation resistance of Nb-Si based multi-component alloys. The laser melting system used mainly includes: Nd-YAG laser, computer system and argon atmosphere protection device. The steps are as follows:

[0047] 1. Using Nb, Si, Ti, Cr, Al, Hf as synthetic raw materials, using vacuum non-consumable arc melting technology to obtain Nb-20Si-24Ti-2Cr-2Al-2Hf alloy master ingot, using wire cutting to cut samples, Polish the surface of the sample, clean it and dry it for later use;

[0048] 2. Fix the Nb-20Si-24Ti-2Cr-2Al-2Hf alloy sample on the workbench, first evacuate the sealed forming cavity into a vacuum state, and then fill it with high-purity argon (99.99%) for protection;

[0049] 3. The laser beam preheats and scans the surface of the Nb-20Si-24Ti-2Cr-2Al-2Hf alloy sample according to the preset scanning path and parameters. The specific preheating parameters: laser power 300W, scanning speed 1800mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com