Construction structure for textile reinforced composite reinforced bar concrete and manufacturing method thereof

A technology of fiber woven mesh and reinforced concrete, which is applied in the direction of building components, building structures, buildings, etc., can solve the problems that the form of the structure cannot be fundamentally changed, the weight of the structure is increased, and there is no obvious problem, so as to solve the cracking of concrete and reduce the The amount of reinforcement and the effect of crack control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with embodiment, and embodiment does not limit the scope of the present invention.

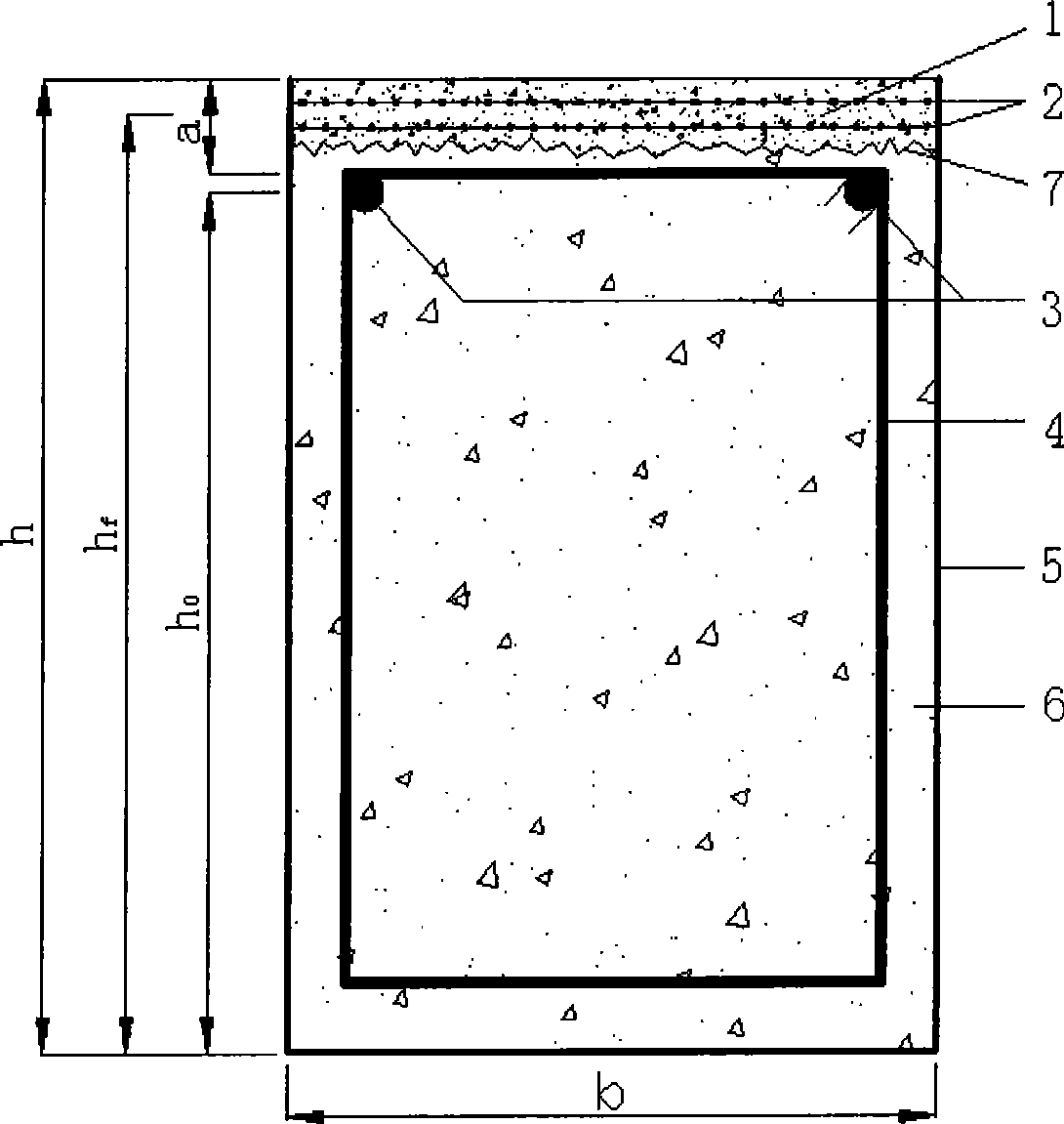

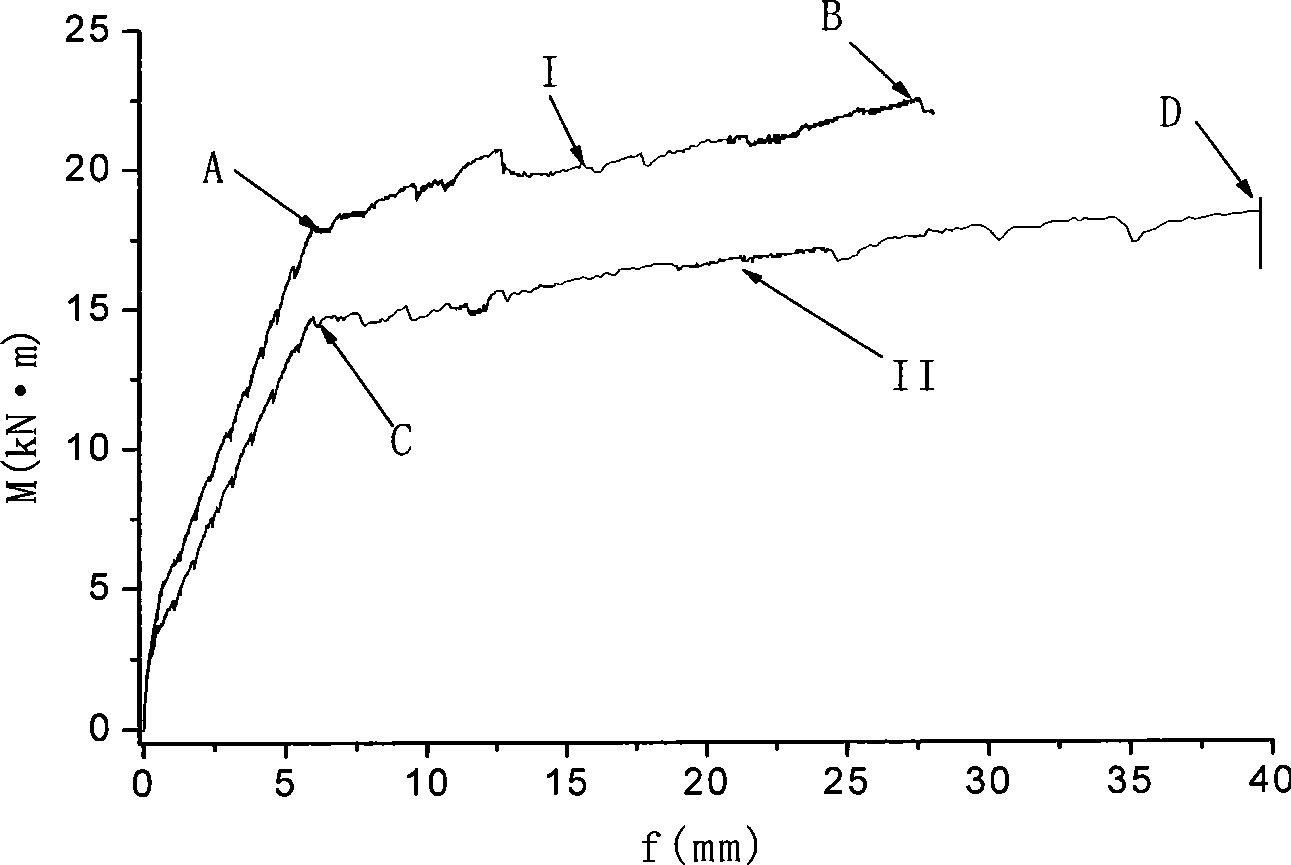

[0031] Make a single-span simply supported rectangular beam with the method of the present invention, the section is as follows figure 1 As shown, the calculated span is 1800mm, the section size is width b=120mm, height h=210mm; the environment category is Class I, and the section bending moment design value M=15kN m

[0032] Designed in accordance with the design specifications for reinforced concrete structures, the concrete strength grade of the structure is C40, and the design compressive strength is f c =19.1N / mm 2 , the minimum reinforcement ratio of the structure is 0.26%, the ultimate reinforcement ratio is 3.50%, and the thickness of the protective layer of the stressed main reinforcement is a=25mm. If three main reinforcements with a diameter of 12mm and a tensile design strength of f y 300N / mm 2 The HRB3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com