Seasonal frozen soil region subgrade structure and construction method thereof

A construction method and technology in permafrost areas, applied to roads, roads, climate change adaptation, etc., can solve the problems of insufficient toughness of plain concrete, easy cracking, impermeability, poor freeze-thaw resistance, etc., to avoid frost heave-thaw settlement , Improve long-term stability and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

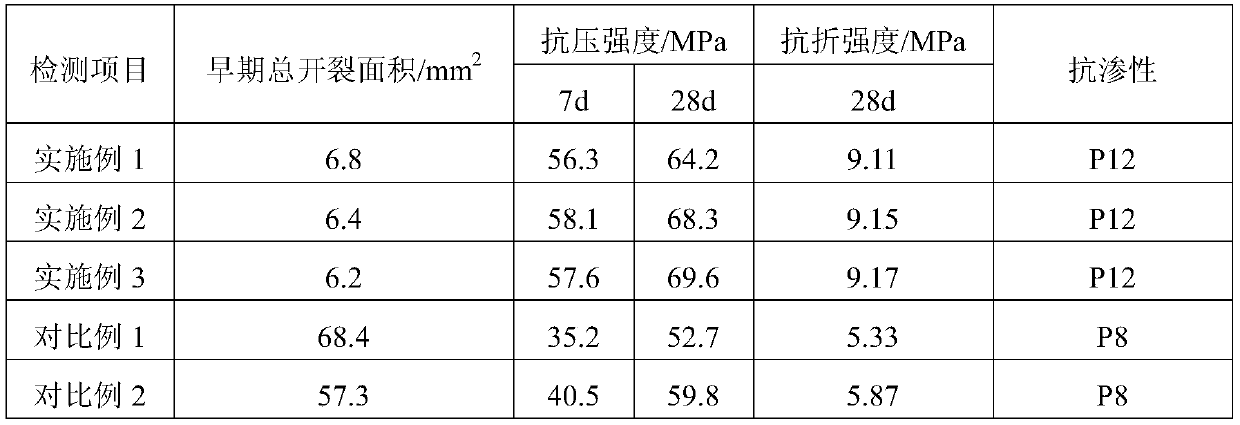

Embodiment 1

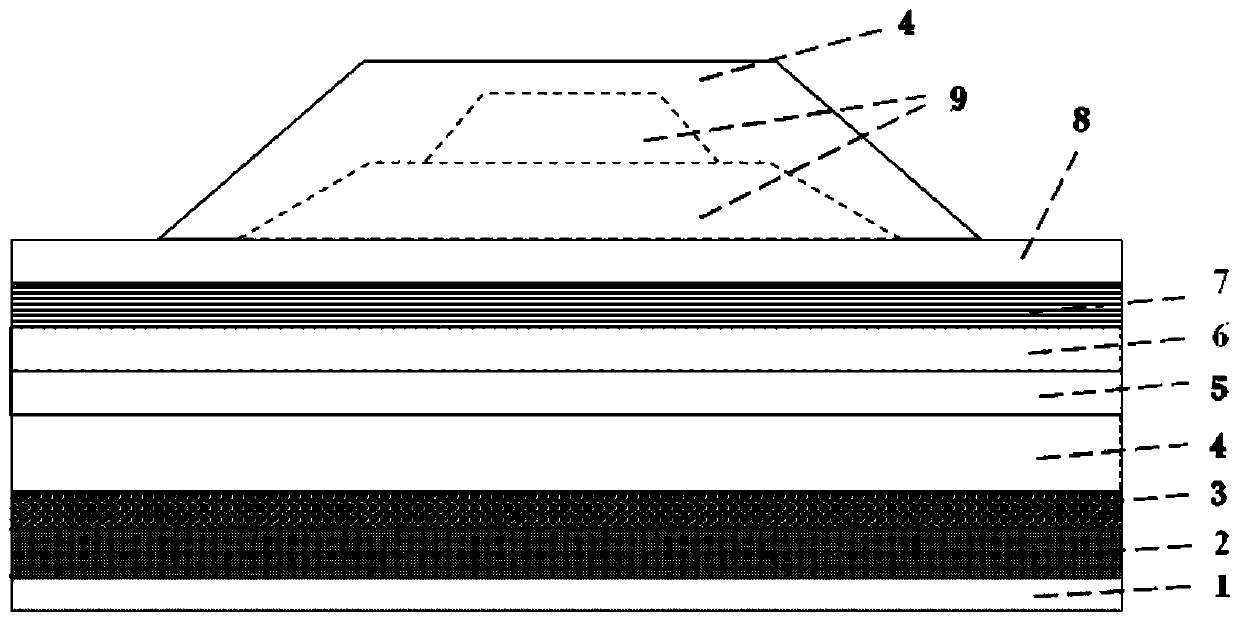

[0027] A subgrade structure in a seasonally frozen soil area, the subgrade structure from bottom to top is a light foam layer, a low liquid limit clay layer, a composite geomembrane layer, a roadbed filler layer, a crushed stone layer, a gravel layer, and a medium-coarse sand layer layer and a composite thermal insulation cushion, the composite thermal insulation cushion is above the fiber concrete layer, the cross section of the fiber concrete layer is double trapezoidal, and the fiber concrete is covered with roadbed filler. Its construction method steps are as follows:

[0028] Step 1: Excavate the frozen soil, level the surface, and lay lightweight foam, with the air bubbles accounting for 45% to 65% of the volume;

[0029] Step 2: lay low liquid limit clay, which can play the role of capillary water isolation, rolling 3 to 4 times;

[0030] Step 3: Lay the composite geomembrane, pave the entire width flat, and the outer edge is exposed by 2 to 3 cm. The composite geomemb...

Embodiment 2

[0046] A subgrade structure in a seasonally frozen soil area, the subgrade structure from bottom to top is a light foam layer, a low liquid limit clay layer, a composite geomembrane layer, a roadbed filler layer, a crushed stone layer, a gravel layer, and a medium-coarse sand layer layer and a composite thermal insulation cushion, the composite thermal insulation cushion is above the fiber concrete layer, the cross section of the fiber concrete layer is double trapezoidal, and the fiber concrete is covered with roadbed filler. Both sides of the fiber concrete layer are designed as slope-shaped steps with a slope of 1:1.5 to 1:1.75, and the edge of the upper trapezoidal slope foot is not less than 40cm from the edge of the lower trapezoidal slope top. The above-mentioned fiber concrete, including the following raw materials in parts by weight: 25 parts of cement, 10 parts of sand, 21 parts of gravel, 18 parts of fly ash, 13 parts of slag, 14 parts of anhydrite, 3 parts of silica...

Embodiment 3

[0053] A subgrade structure in a seasonally frozen soil area, the subgrade structure from bottom to top is a light foam layer, a low liquid limit clay layer, a composite geomembrane layer, a roadbed filler layer, a crushed stone layer, a gravel layer, and a medium-coarse sand layer layer and a composite thermal insulation cushion, the composite thermal insulation cushion is above the fiber concrete layer, the cross section of the fiber concrete layer is double trapezoidal, and the fiber concrete is covered with roadbed filler. Both sides of the fiber concrete layer are designed as slope-shaped steps with a slope of 1:1.5 to 1:1.75, and the edge of the upper trapezoidal slope foot is not less than 40cm from the edge of the lower trapezoidal slope top. The above-mentioned fiber concrete includes the following raw materials in parts by weight: 28 parts of cement, 12 parts of sand, 16 parts of crushed stone, 15 parts of fly ash, 12 parts of slag, 12 parts of anhydrite, 4 parts of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com