Preparation method for deuterium-containing metal film target

A metal thin film and metal technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of reducing the bonding force between the film and the substrate, reducing the deuterium absorption performance at high temperature, and pollution of the hydrogen storage metal film. , to achieve the effect of reducing oxides and carbides, improving mechanical properties and controlling brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

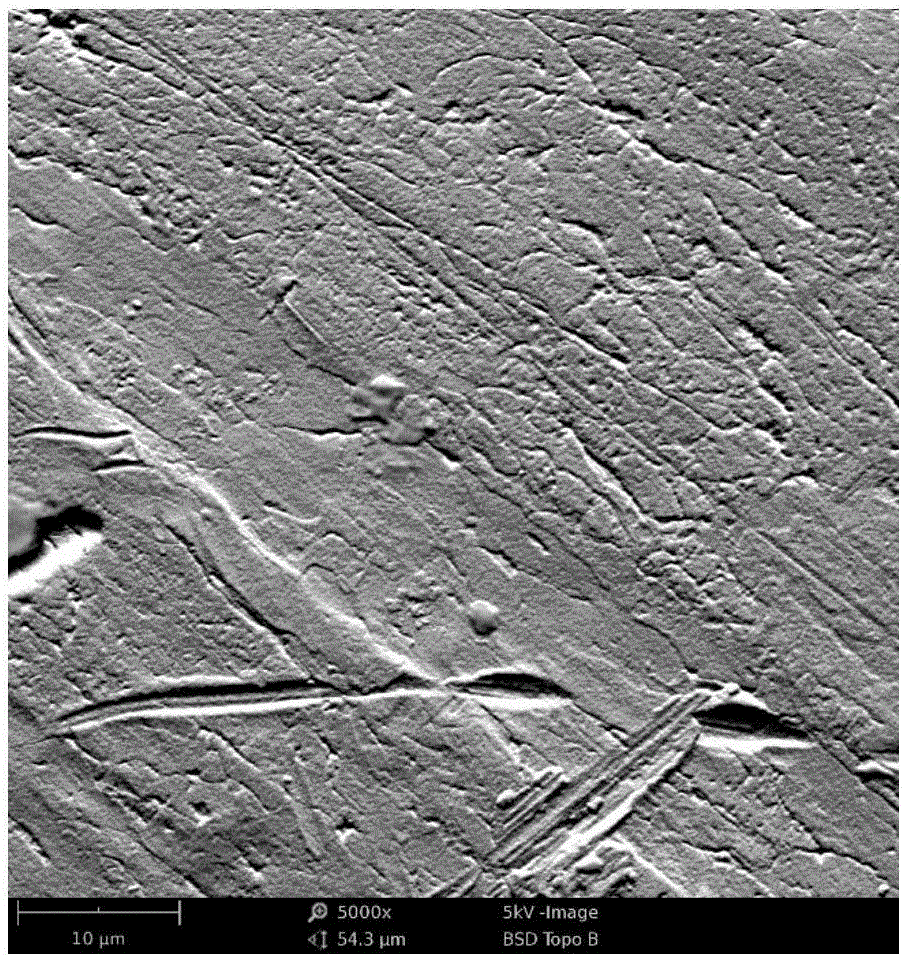

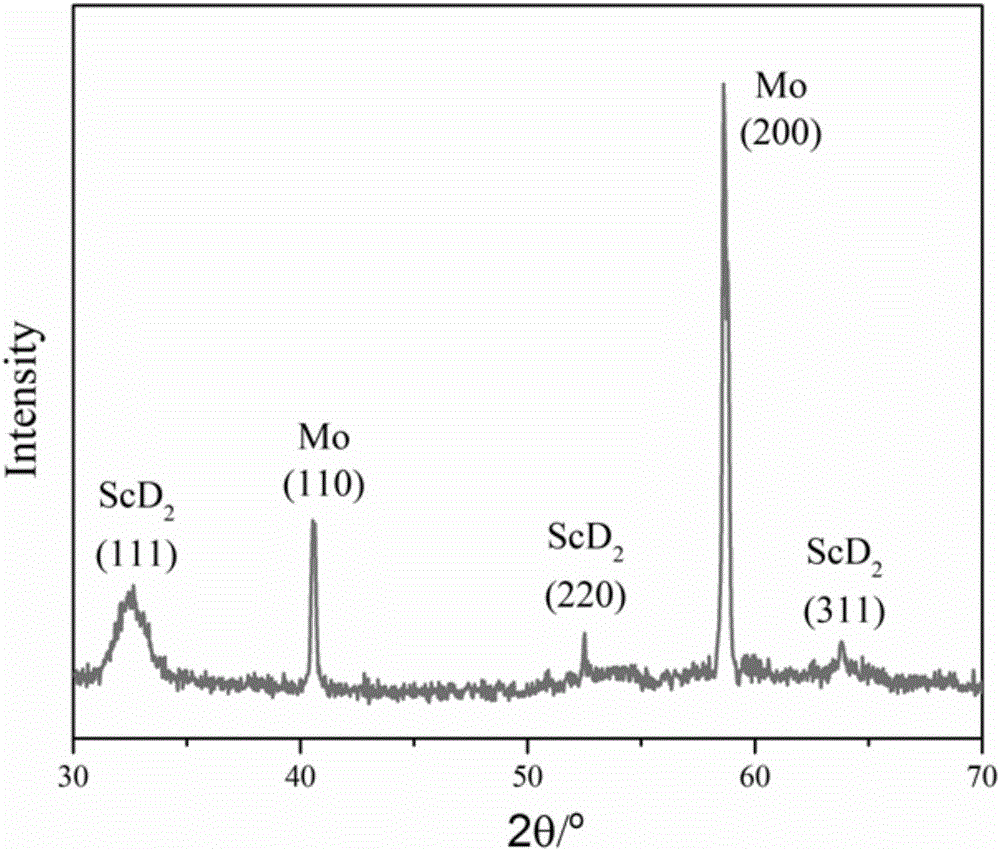

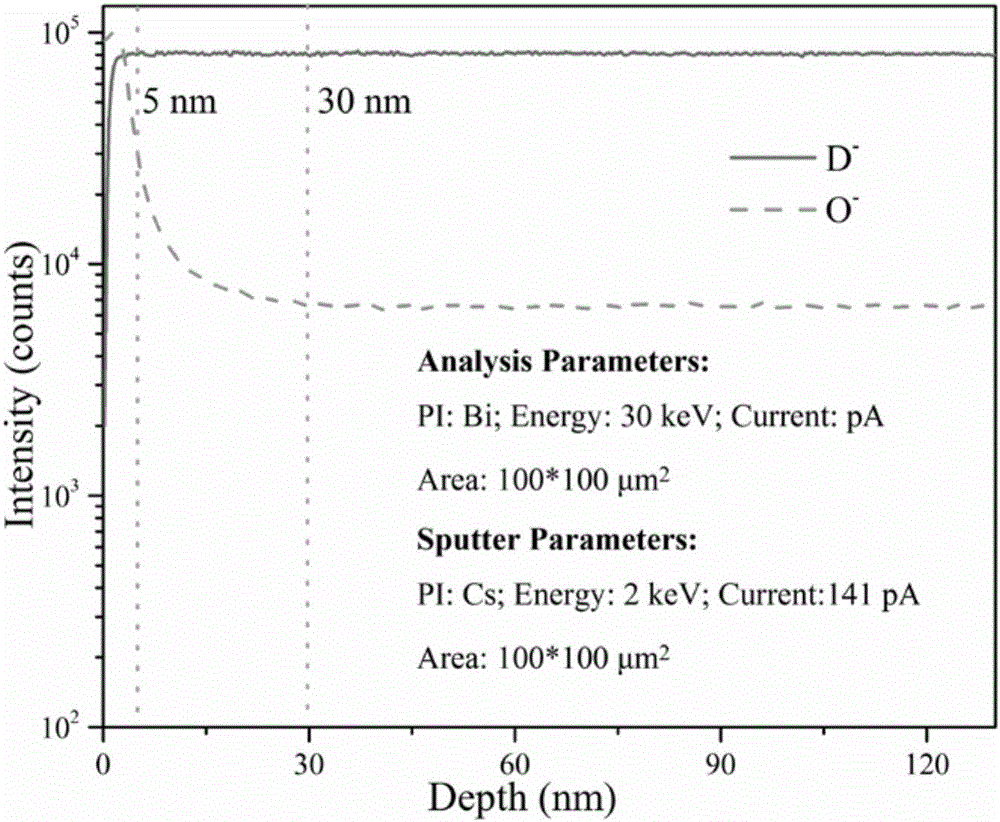

[0041] A method for preparing a deuterium-containing metal thin film target of the present invention, taking the magnetron sputtering coating technology as an example, the preparation process of the molybdenum-based deuterated scandium thin film target is carried out according to the following steps:

[0042] (a1) adopting 99.99% pure molybdenum with a thickness of 1mm, processed into a disc as the substrate substrate of the deuterium-containing metal thin film target;

[0043] (a2) The thickness of the substrate substrate is 0.5-1mm, and it is polished on one side, and the polishing accuracy is not higher than 0.4μm;

[0044] (a3) Degrease the polished substrate first in hot alkali, then remove the oxide layer in weak acid, then wash it with deionized water, and then put it into alcohol or acetone for ultrasonic cleaning for 5 minutes;

[0045] (a4) Put the cleaned substrate into a plasma cleaning machine, and use Ar plasma to clean the surface;

[0046] (b1) The substrate s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com