Nickel-based high temperature alloy and design method thereof

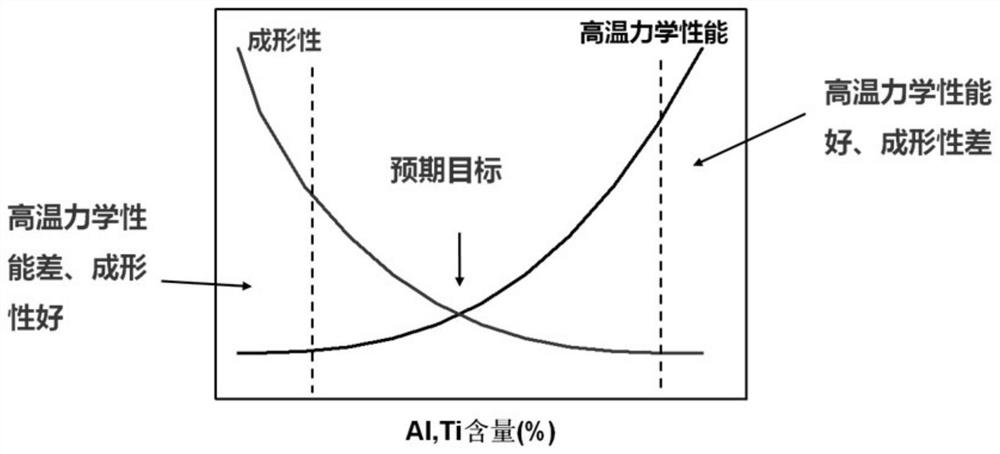

A technology of nickel-based superalloy and design method, applied in additive manufacturing, additive processing, etc., can solve the problems of easy cracking, low high temperature strength of alloy, poor formability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment is designed for a nickel-based high-temperature alloy for adding materials, mainly including the following steps:

[0052] 1) The initial choice of alloy ingredients

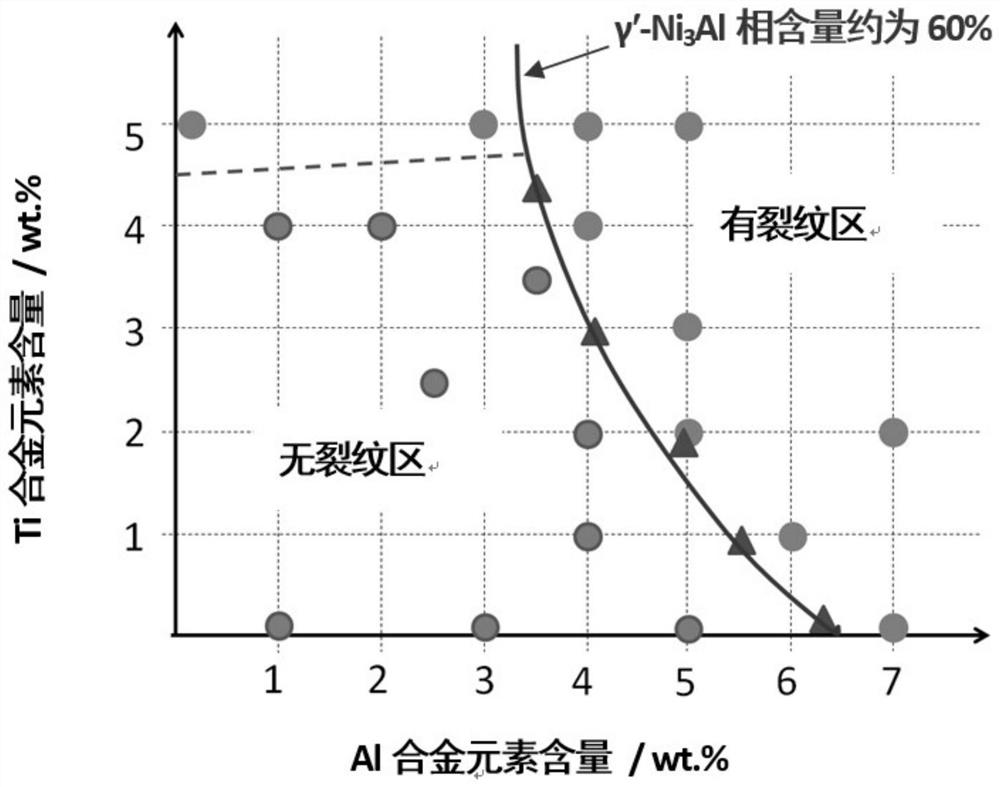

[0053] According to the principle of traditional high-temperature alloy component design, a component of solid solution elements and grain boundary reinforcing elements in nickel-based high-temperature alloys is generally determined, specifically Ni-8Cr-5CO-2MO-5W-0.05C (regarding the nickel-based high temperature alloy CR (8 wt%), CO (5 wt%), MO (2 wt%), W (5 wt%), C (0.05 wt%), Al (0 ~ 7% by weight), Ti (0 ~ 5 wt%), Ni (margin)).

[0054] Then, adjust the γ'-Ni in the nickel-based high temperature alloy. 3 The content of the second phase shaped element Al and Ti (the adjustment range of Al 0 to 7% by weight, Ti is 0 to 5 wt%). Calculate the γ'-Ni in alloy using thermo-coal thermodynamics computing software. 3 The impact of the second phase content (shown in Table 1). The electronic vacancies...

Embodiment 2

[0071] This embodiment is designed for a nickel-based high-temperature alloy for adding materials, mainly including the following steps:

[0072] 1) The initial choice of alloy ingredients

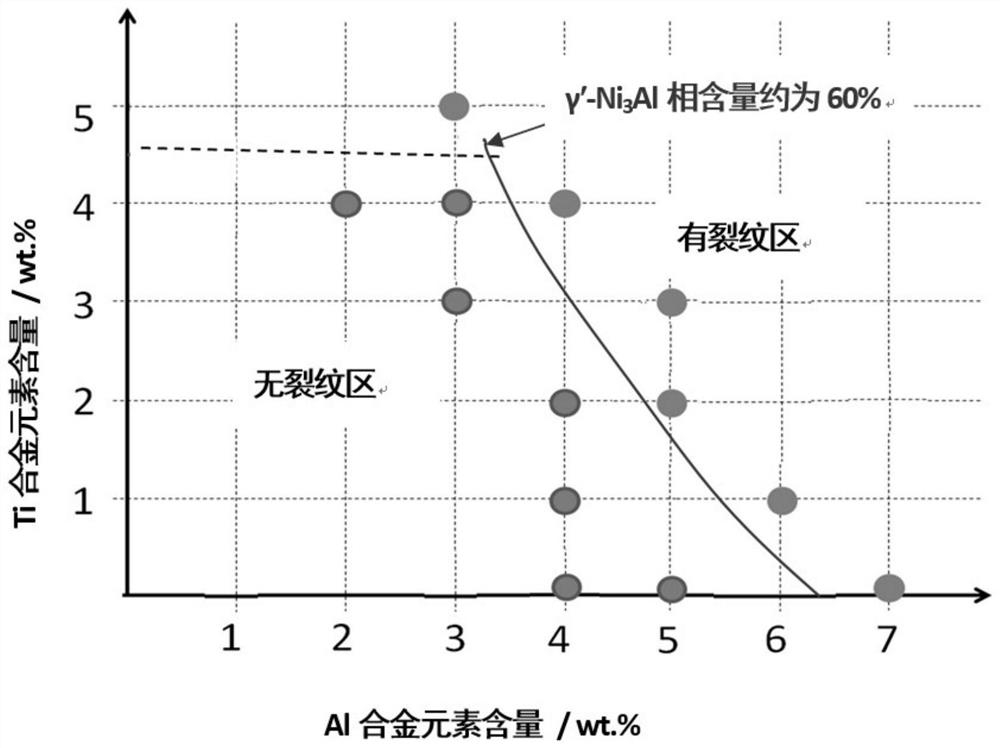

[0073] According to the principle of traditional high-temperature alloy component design, a hydrate-soluble element and a grain boundary reinforcement element in a high temperature alloy are generally determined, specifically Ni-10Cr-10CO-3MO-2W-0.5HF-0.05C (regarding the nickel base high temperature Alloy, including Cr (10%), CO (10 wt%), W (2 wt%), HF (0.5 wt%), C (0.05 wt%), Al (0 ~ 7%), Ti (0 ~ 5 wt%), Ni (margin)).

[0074] Then, adjust the γ'-Ni in the nickel-based high temperature alloy 3 The content of the second phase shaped element Al and Ti (the adjustment range of Al 0 to 7% by weight, Ti is 0 to 5 wt%). The alloy in different Al, Ti content is calculated using the thermo-Calc thermodynamics software γ'-Ni. 3 Al second phase content (content regulation of Al and Ti of this example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com