Cold-welding restoring method for tooth surface notches of presser iron-casting press roll shell

A repair method and press roll technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as longitudinal cracks in the fusion zone, easy white structure, and sensitive cooling speed, so as to reduce welding stress and repair parts Intact, reducing the effect of welding stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

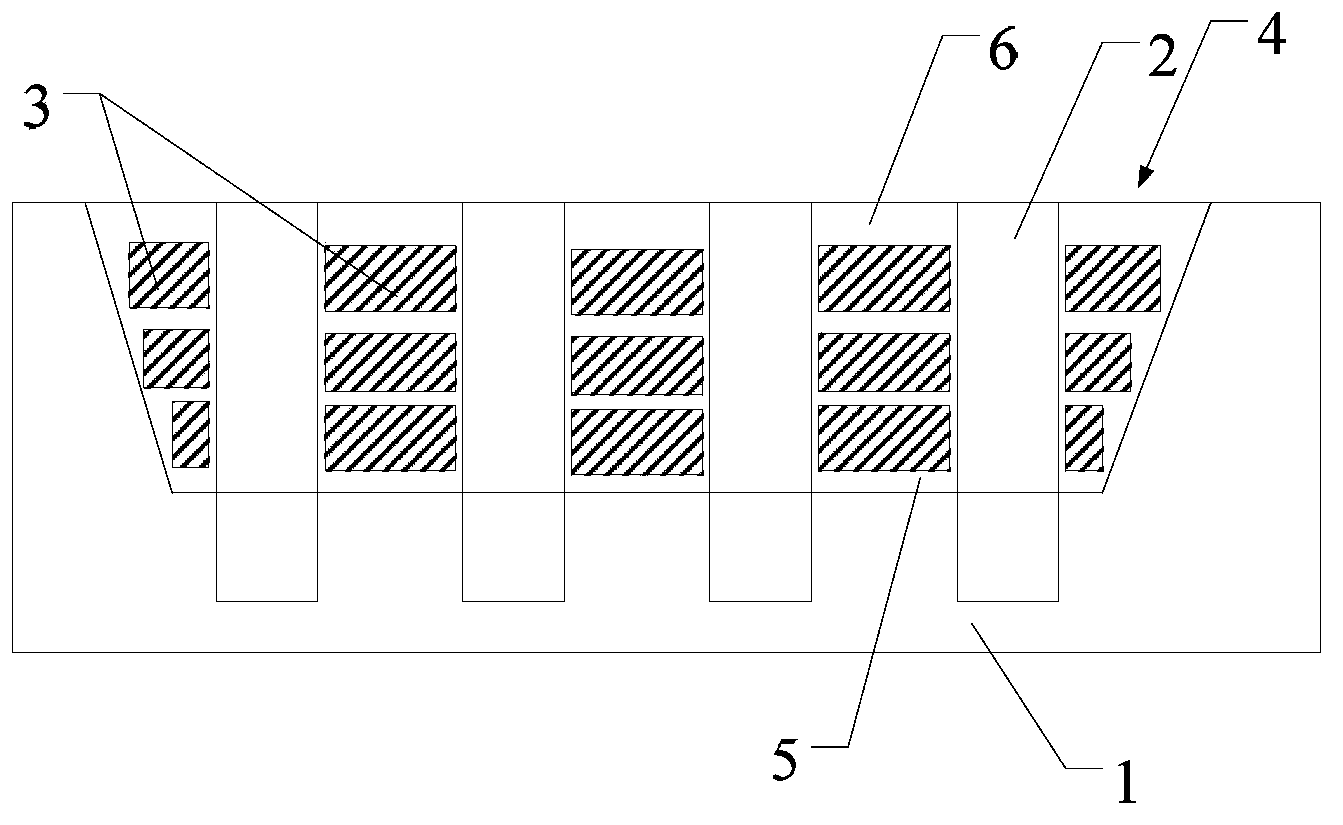

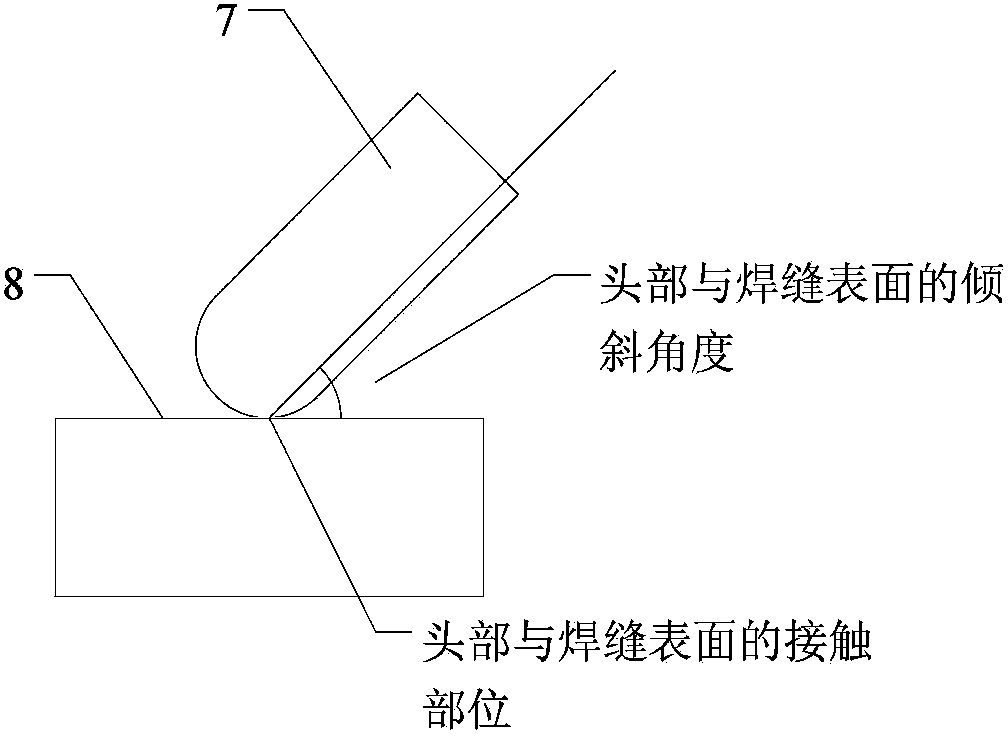

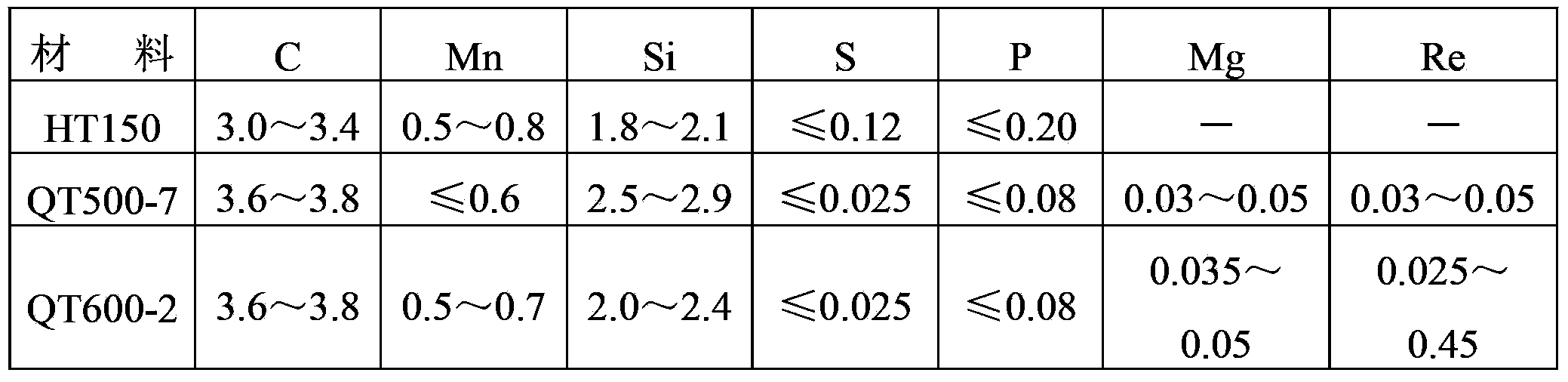

[0046] The invention provides a cold welding repair method for tooth surface chipping of cast iron press roll shells of press machines, comprising the following steps: the press roll shell has a plurality of teeth, wherein at least one tooth has at least one chipping, the A plurality of teeth have at least two breakouts; for any breakout, divide the breakout into n segments distributed continuously along the length direction of the breakout according to the length of the breakout; for any two breakouts, take turns to Two cracks are welded, select a section on the first crack to weld, after the welding is completed, quickly hammer the weld seam, then select a section on the first crack to weld, after the welding is completed, quickly hammer the weld When the welding seam of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com