Transparent curtain wall system free from ribbed plates and installation method thereof

A transparent and curtain wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of limited wind load of supporting glass rib, complicated installation, large space occupied by glass rib, etc. Small, easy to process and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

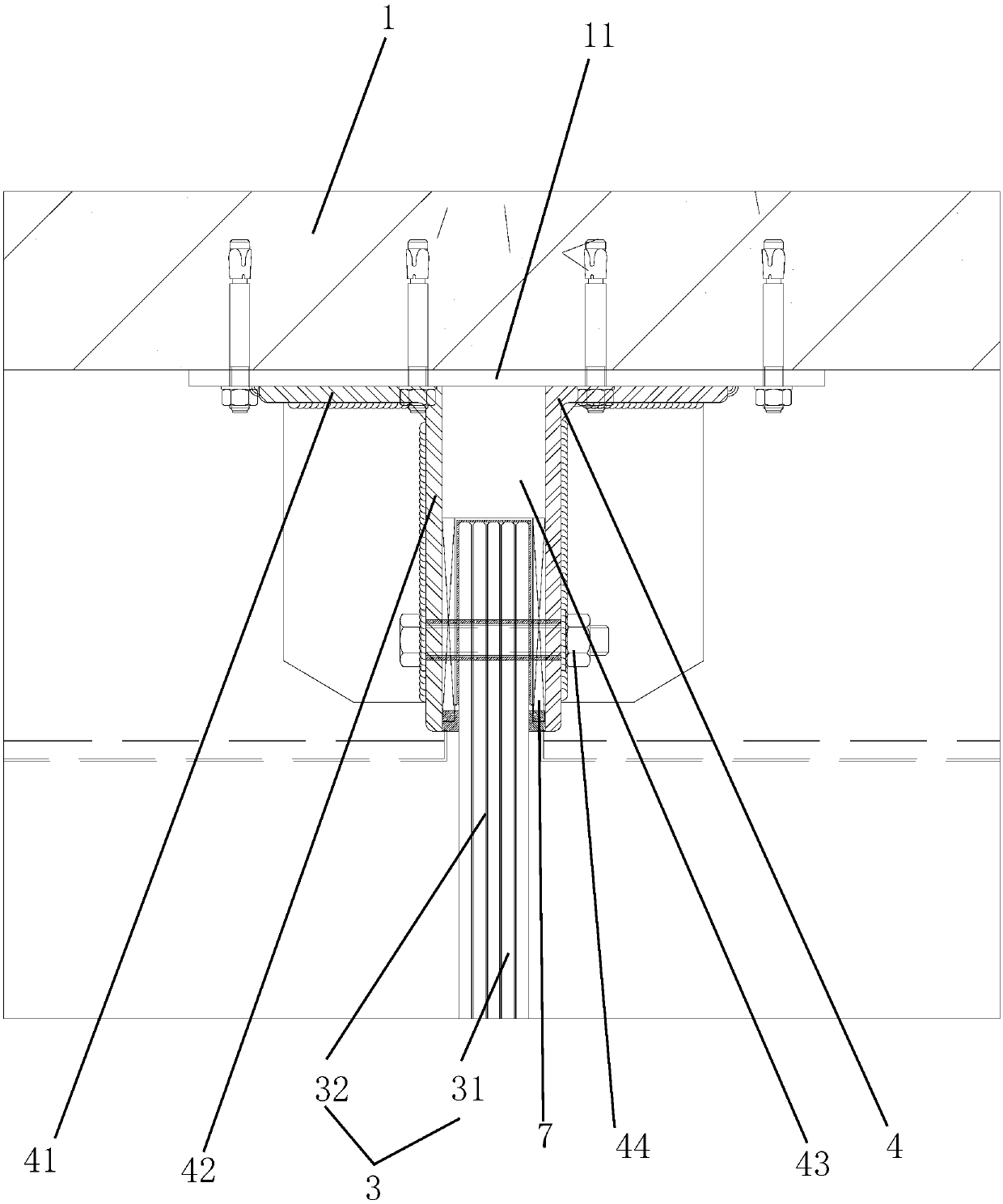

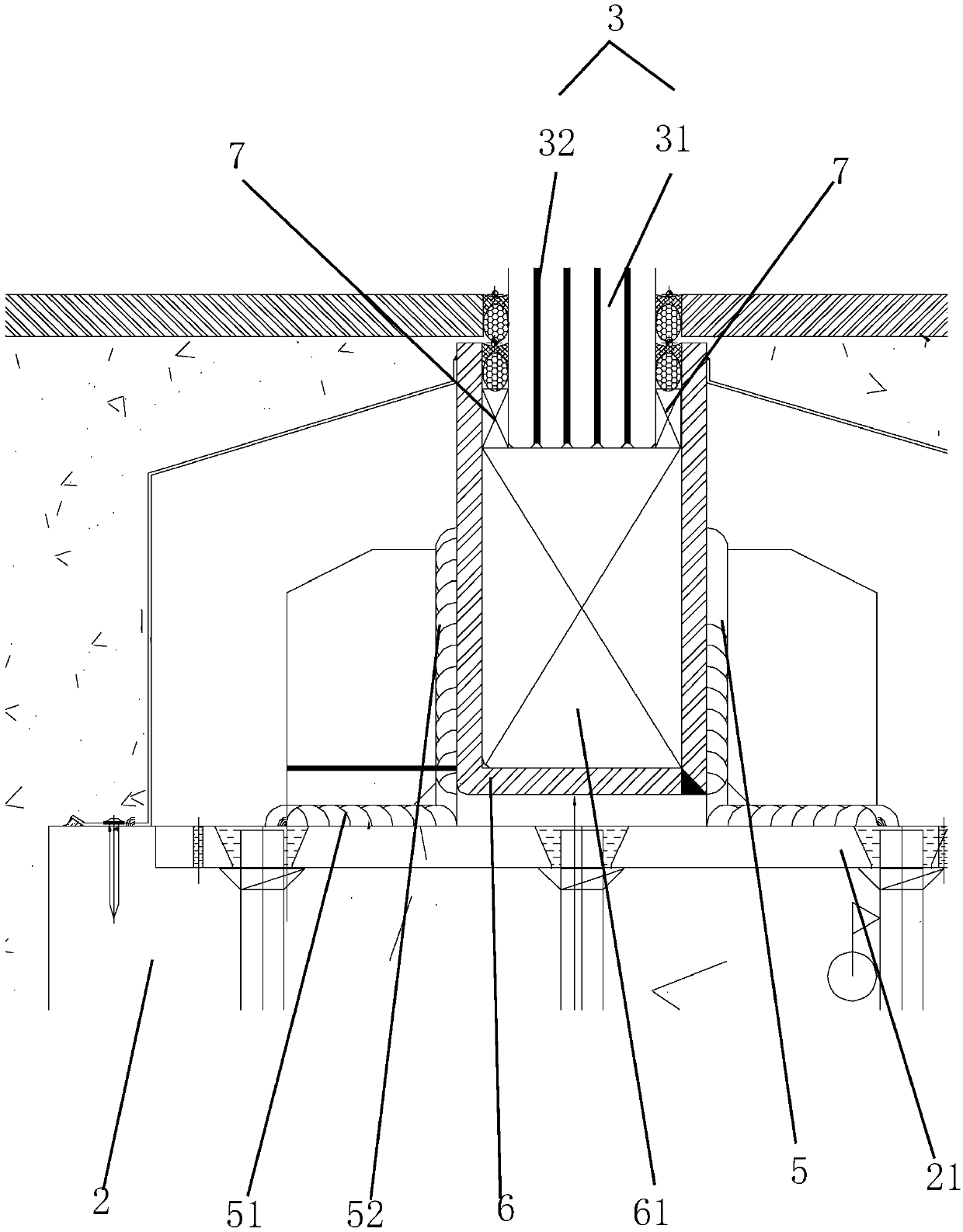

[0028] Such as figure 1 , figure 2 As shown, the present invention provides a ribless transparent curtain wall system, which includes a building top structure 1, a building bottom structure 2 and a glass panel 3 between them.

[0029] The roof structure 1 of the building is provided with a structural roof beam 11, and the bottom surface of the structural roof beam 11 is fixed with two oppositely arranged first adapters 4, and the section of the first adapter 4 is inverted L-shaped, including a roof 41 and the first side plate 42 . The top plate 41 is fixedly connected to the structural top beam 11 , and a first installation groove 43 is formed between the two first side plates 42 . The building bottom structure 2 is provided with a structural bottom beam 21, and the top surface of the structural bottom beam 21 is fixed with two oppositely ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com