Preparation method of low-cost paper environment-friendly take-out meal box

A low-cost, paper-based technology, applied in textiles and papermaking, chemical production of bast fibers, applications, etc., can solve the problems of low strength, poor resistance to bending, poor high temperature tolerance, and high price of tableware, and achieve compactness Improvement, toughness, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

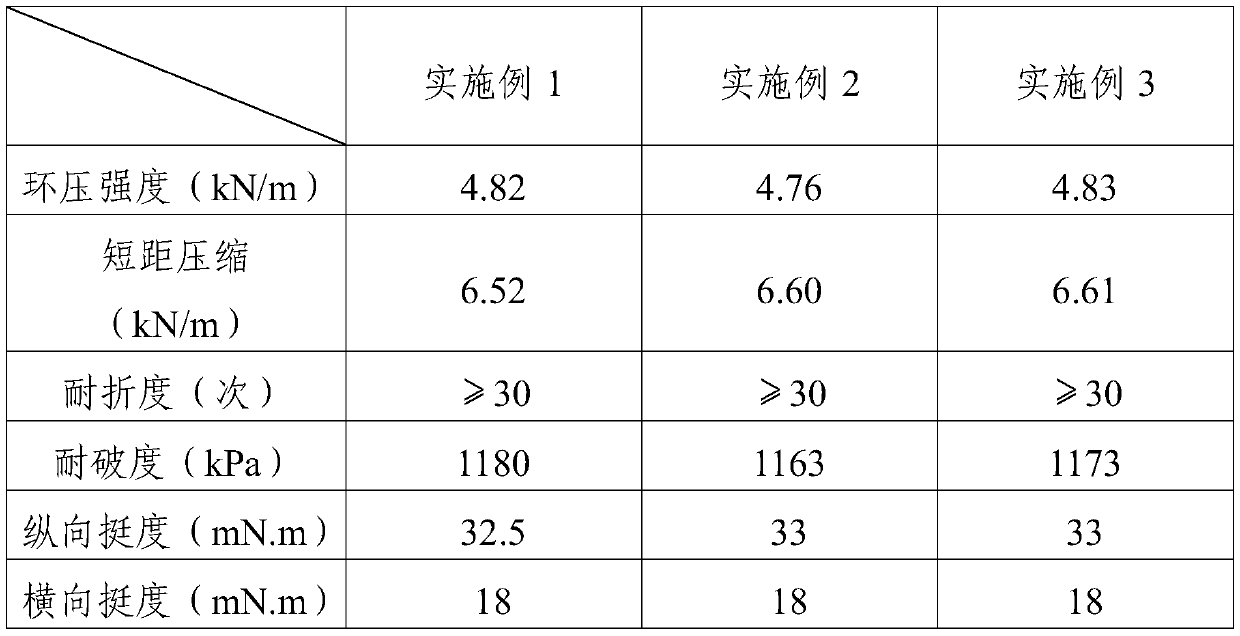

Embodiment 1

[0029] A preparation method of a low-cost paper-based environment-friendly takeaway lunch box is as follows:

[0030] Cut the wheat stalks to 5-8cm and split them longitudinally into 4 parts, add them to 18% sodium hydroxide solution, heat up to 85°C, soak for 1.5 hours, filter out, wash with water until neutral, and then centrifuge and dehydrate , placed in a cool and dark place for 3 days, and then placed in an electric drying oven at 55°C to dry to constant weight to obtain wheat straw fibers. After soaking ramie in 8% sodium hydroxide solution at a temperature of 72°C for 18 minutes , take out water and wash to neutrality, join in the pectinase enzyme solution that mass concentration is 5%, also include calcium chloride, sodium dihydrogen phosphate and mannitol in the pectinase enzyme solution, adjust pH to 3 with citric acid -5. After 2.2 hours of enzymatic hydrolysis, remove and wash with water until neutral, then add to 20% sodium hydroxide solution and soak for 28 minu...

Embodiment 2

[0032] A preparation method of a low-cost paper-based environment-friendly takeaway lunch box is as follows:

[0033]After the wheat straw is cut to 5-8cm, it is split longitudinally into 4 parts, added to a sodium hydroxide solution with a mass concentration of 22% and heated to 90°C for soaking for 2 hours, then filtered out, washed with water until neutral, and centrifugally dehydrated. Place it in a cool and dark place for 4 days, then place it in an electric drying oven at 60°C and dry to constant weight to obtain wheat straw fiber, soak the ramie in a sodium hydroxide solution with a temperature of 72°C and a mass concentration of 5-10% for 16 minutes Finally, after taking out water and washing to neutrality, join in the pectinase enzyme liquid that mass concentration is 6%, also comprise calcium chloride, sodium dihydrogen phosphate and mannitol in the pectinase enzyme liquid, adjust pH to 3-5. After 2 hours of enzymatic hydrolysis, remove and wash with water until neut...

Embodiment 3

[0035] A preparation method of a low-cost paper-based environment-friendly takeaway lunch box is as follows:

[0036] After the wheat straw is cut to 5-8cm, it is split longitudinally into 4 parts, added to a sodium hydroxide solution with a mass concentration of 18% and heated to 90°C for soaking for 3 hours, then filtered out, washed with water until neutral, and centrifugally dehydrated. After placing it in a cool and dark place for 4 days, it was placed in an electric drying oven at 60°C and dried to constant weight to obtain wheat straw fibers. The ramie was soaked in a sodium hydroxide solution with a temperature of 72°C and a mass concentration of 8% for 14 minutes. After taking out the water and washing to neutrality, it is added to the pectinase enzyme solution with a mass concentration of 5%. The pectinase enzyme solution also includes calcium chloride, sodium dihydrogen phosphate and mannitol, and the pH is adjusted to 3- 5. After 2 hours of enzymatic hydrolysis, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com