Production system and method for steel fiber reinforced concrete electric pole

A technology of steel fiber reinforced concrete and production system, which is applied in chemical instruments and methods, clay preparation devices, mixing operation control, etc., can solve the problems of unable to make up for insufficient end strength, unguaranteed production quality, high labor intensity, etc. Achieve compact structure, reduce transportation costs and energy consumption, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

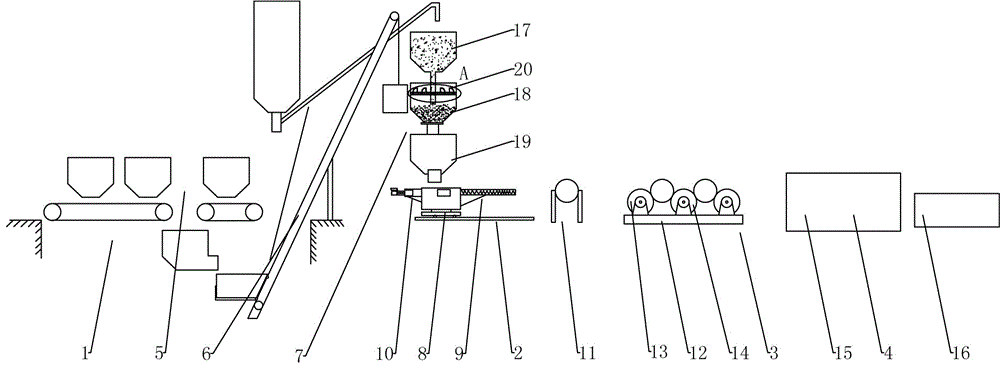

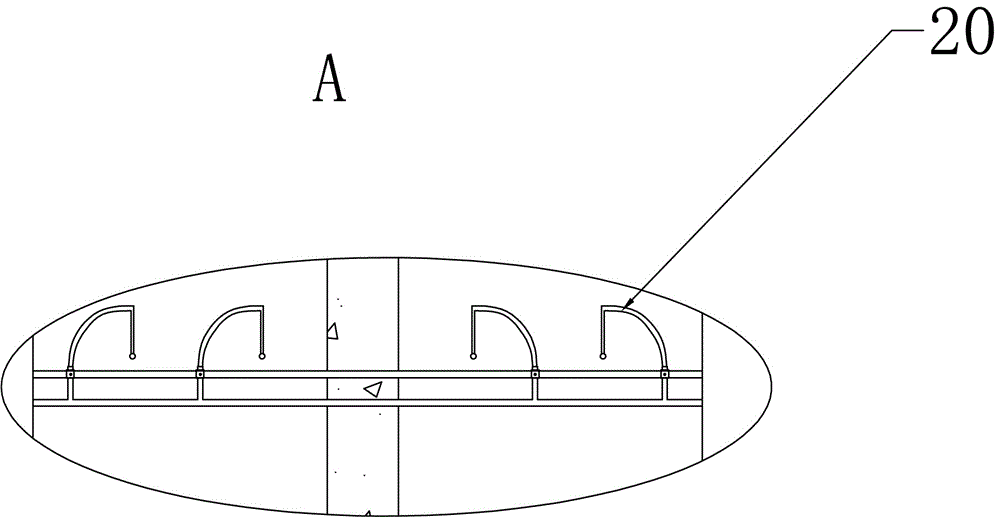

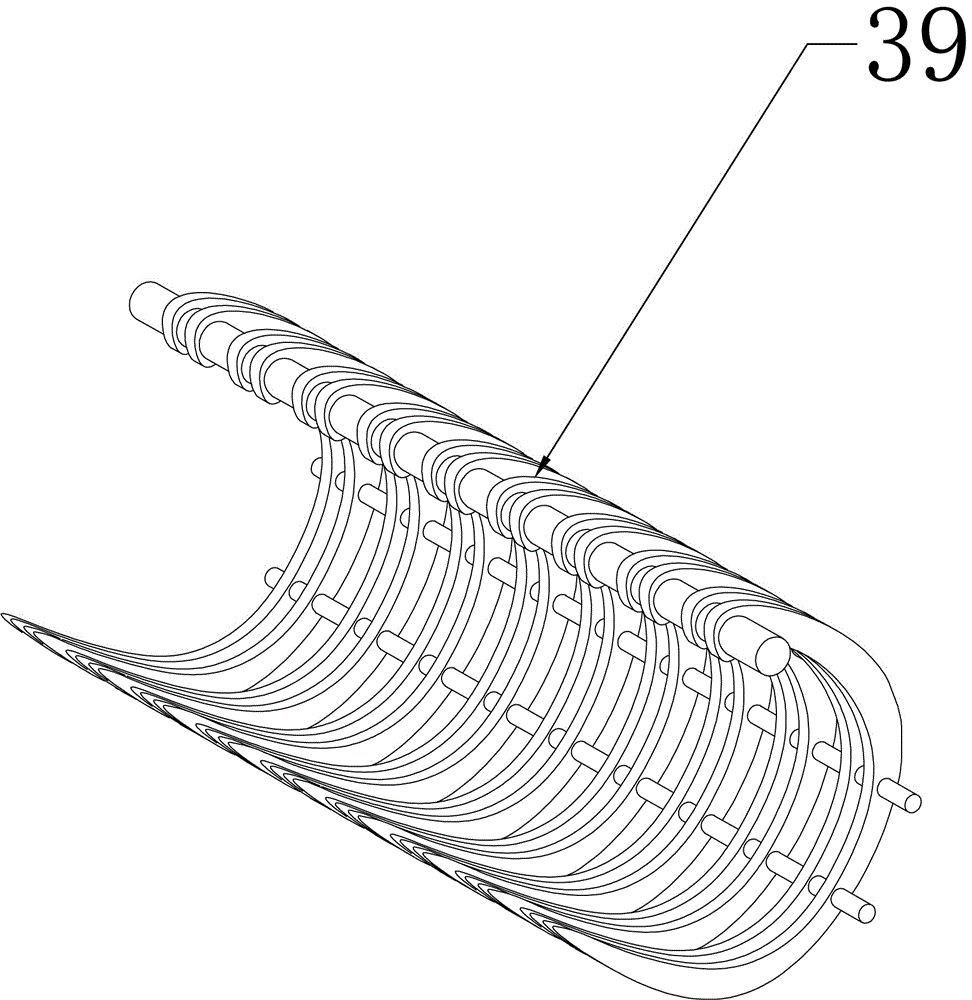

[0034] like figure 1 As shown, a steel fiber concrete pole production system includes concrete mixing and conveying equipment 1, feeding equipment 2, centrifugal equipment 3 and maintenance equipment 4, and the concrete mixing and conveying equipment 1 includes a weighing and conveying mechanism 5, and the weighing and conveying The mechanism 5 is connected with the multi-stage mixing mechanism 7 through the transmission mechanism 6, wherein the weighing conveying mechanism 5 includes a hopper for sand, cement and gravel respectively, and two weighing conveyor belts are arranged at the lower end of the hopper, and the materials fall into the Mix in the lower silo, and flow into the conveyor bucket from the inclined material port at one end, and the conveyor bucket is driven by the hoist to drive the wire rope to the multi-stage mixing and stirring mechanism; The upper two sides are respectively provided with a centrifugal feeding mechanism 9 and a secondary centrifugal feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com