Preparation method for lead-zinc-silver tailing low-temperature-sintered encaustic brick glaze

A technology of glazed bricks and glazes, which is applied in the field of preparation of low-fired glazed bricks from lead-zinc-silver mine tailings, can solve the problems of high energy consumption, unsuitability, and environmental pollution, and achieve good wear resistance, easy molding, good hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

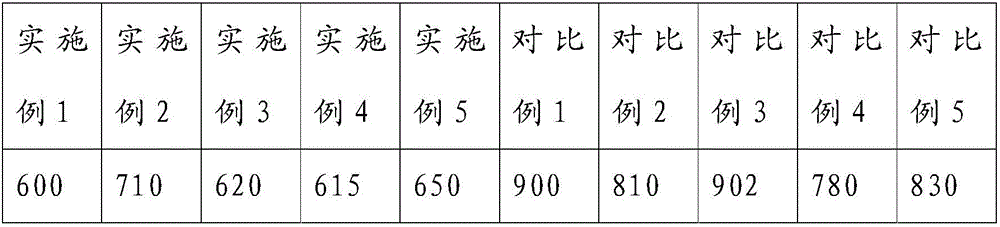

Examples

preparation example Construction

[0022] A method for preparing lead-zinc-silver tailings low-fired glazed bricks, comprising the following steps:

[0023] (1) Prepare materials: prepare the body raw materials and glaze raw materials of the glazed brick:

[0024] The glazed brick body consists of the following raw materials in parts by weight:

[0025] 120 parts of lead-zinc-silver mine tailings; 80 parts of high bauxite; 9 parts of mullite; 6 parts of nano-alumina; 6 parts of titanium dioxide; 3 (VO 4 ) 2 6 parts; 6 parts of zinc oxide; 6 parts of potassium carbonate; 6 parts of sodium tetraborate decahydrate; 6 parts of water glass;

[0026] (2) Green body mixing, molding, and drying: weigh the green body raw materials according to the formula, wet ball mill the green body raw materials to a 200-mesh sieve, and the sieve residue is 0.3wt%; dehydrate the sieved slurry into a mud cake, and aged for 5 days; followed by cold isostatic pressing, followed by drying;

Embodiment 1

[0031] A method for preparing lead-zinc-silver tailings low-fired glazed brick glaze, comprising the following steps:

[0032] (1) Prepare materials: prepare the raw materials of the glaze of the glazed brick: the glazed brick glaze is made up of the following raw materials in parts by weight:

[0033] 44 parts of chromium tin purple material; 9 parts of cryolite; 9 parts of mullite; 4 parts of nano-alumina; 4 parts of nano-titanium dioxide; 4 parts of Ca3(VO4)2; 4 parts of zinc oxide; 4 parts of sodium borate; 2 parts of phosphoric acid; 150 parts of n-amyl alcohol; 150 parts of ethanol; 2 parts of zirconium silicate; 2 parts of methyl cellulose; 270 parts of water;

[0034] (2) Raw material mixing: raw material mixing, first mix isopropanol and ethanol to form a mixed alcohol, then add chromium tin purple material, stir for 5 minutes, add cryolite and mullite after stirring and mixing, then add nano-alumina, nano Titanium dioxide, Ca3(VO4)2, zinc oxide, lithium carbonate, s...

Embodiment 2

[0036] A method for preparing lead-zinc-silver tailings low-fired glazed brick glaze, comprising the following steps:

[0037] (1) Prepare materials: prepare the raw materials of the glaze of the glazed brick: the glazed brick glaze is made up of the following raw materials in parts by weight:

[0038] 50 parts of chromium tin purple material; 9 parts of cryolite; 9 parts of mullite; 4 parts of nano-alumina; 4 parts of nano-titanium dioxide; 4 parts of Ca3(VO4)2; 4 parts of zinc oxide; 4 parts of sodium borate; 2 parts of phosphoric acid; 150 parts of n-amyl alcohol; 150 parts of ethanol; 2 parts of zirconium silicate; 2 parts of methyl cellulose; 300 parts of water;

[0039] (2) Raw material mixing: raw material mixing, first mix isopropanol and ethanol to form a mixed alcohol, then add chromium tin purple material, stir for 8 minutes, add cryolite and mullite after stirring and mixing, then add nano-alumina, nano Titanium dioxide, Ca3(VO4)2, zinc oxide, lithium carbonate, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com