Collision reinforcement material for vehicle

A technology for reinforcing materials and vehicles, applied in vehicle parts, bumpers, doors, etc., can solve problems such as reaction force drop, wall member deformation, weight increase, etc. long lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

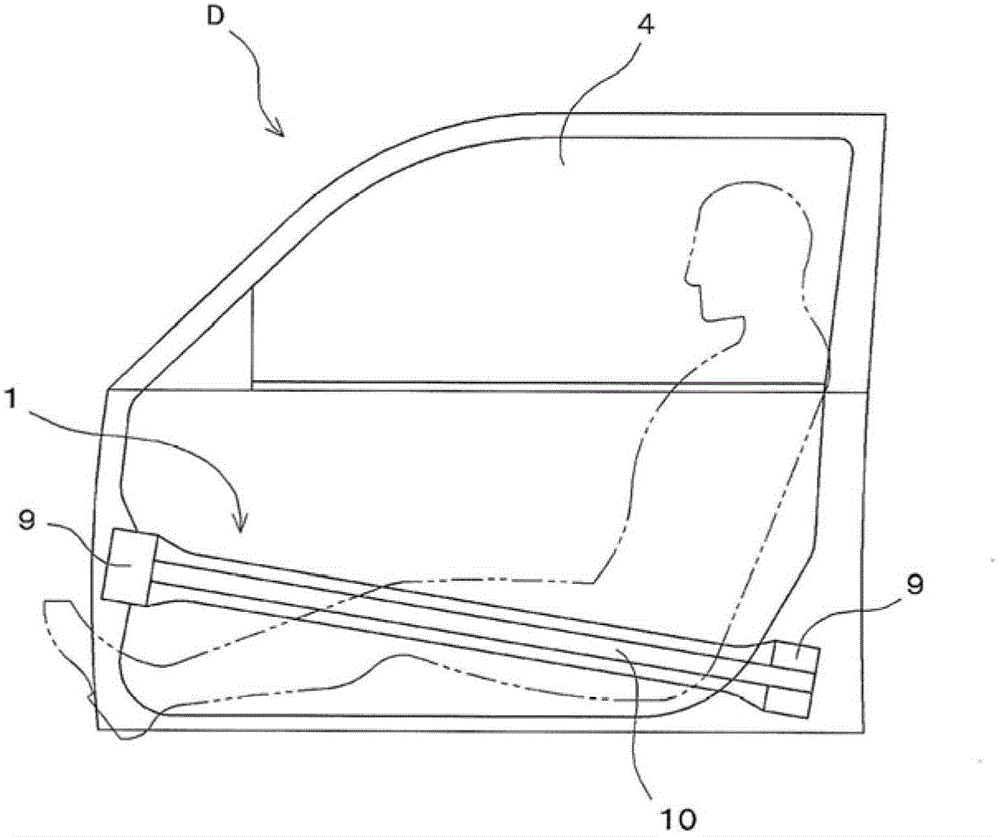

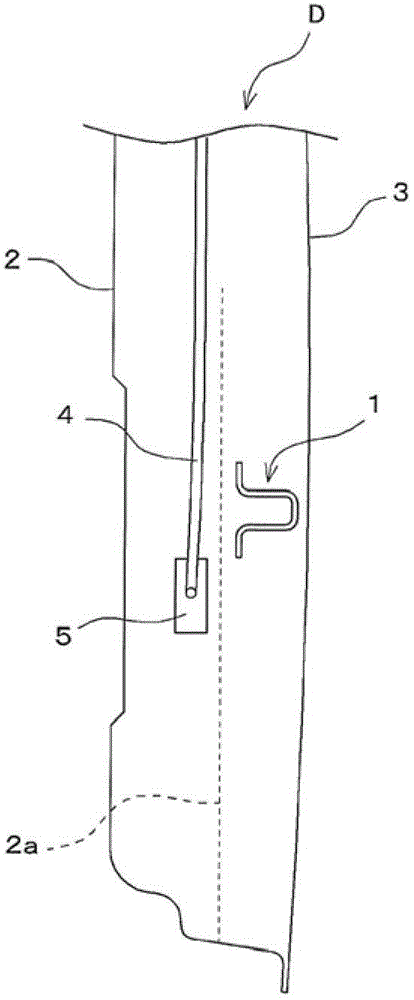

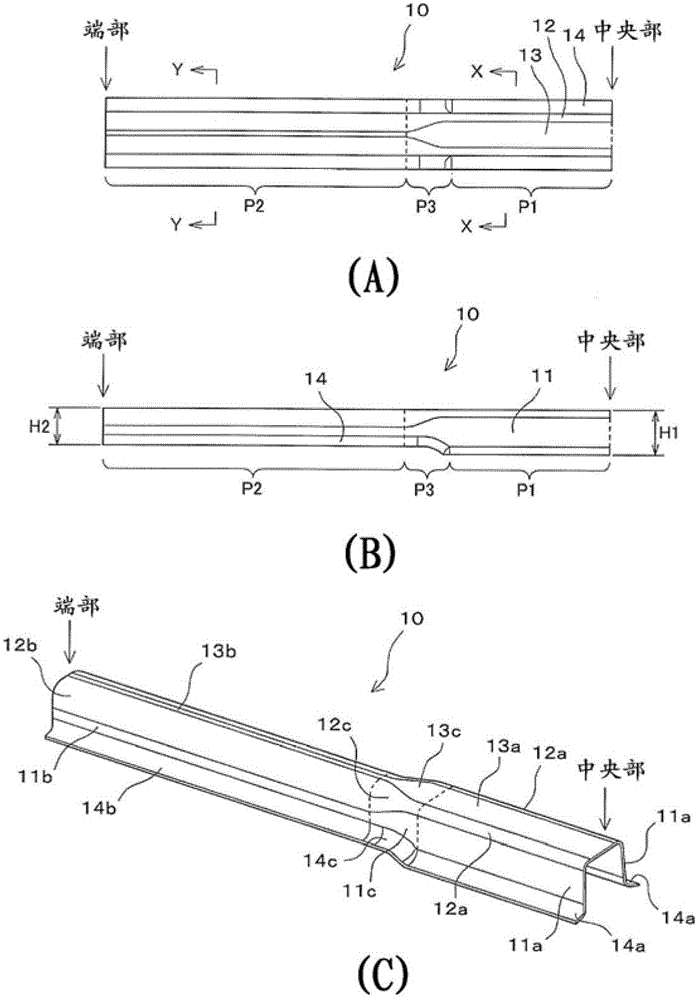

[0058] Such as figure 1 As shown, bracket portions 9 are integrally formed at both ends in the longitudinal direction of the elongated main body portion 10 in the door bumper 1 of Example 1, respectively. image 3 A plan view, a side view, and a perspective view showing the door impact bar 1 in a state in which the main body portion 10 other than the bracket portion 9 is cut from the center. The main body portion 10 of the door bumper 1 includes: a pair of facing wall portions 11 (11a, 11b, 11c); Between the front end portions; a pair of corner (corner) bent portions 12 (12a, 12b, 12c), the front end portion of the wall portion 11 is connected with the central flange portion 13; and a pair of outer peripheral flange portions 14 (14a, 14b, 14c ), from the respective rear ends of the two wall parts 11 to the outward direction ( image 3 (A) up and down direction, Figure 4 left and right direction) stick out. Such as Figure 4 As shown, since a pair of wall portions 11, a c...

example 2

[0076] Figure 9 Example 2 of the present invention is shown. Such as Figure 9 (A)~ Figure 9 As shown in (C), the main body portion of the door bumper bar 20 of Example 2 includes: a central flange portion 33, a pair of corner bending portions 32, a pair of wall portions 31, and a pair of outer peripheral flange portions 34, which are the same as those of Example 1. same. In Example 2, the third portion (gradient portion) P23 of the door impact bar 20 is formed longer than the third portion P3 of Example 1 in the length direction.

[0077] The corner bending portion 32c of the third portion (gradient portion) P23 includes: a fixed-length section adjacent to the second portion P22 and maintaining the same cross-sectional area as the second portion P22; and a remaining section adjacent to the first portion P21 . In the remaining section, the cross-sectional area of the corner bending portion 32c gradually becomes narrower as it approaches the first portion P21.

[0078...

example 3

[0083] Figure 11 Example 3 of the present invention is shown. Such as Figure 11 (A)~ Figure 11 As shown in (C), the main body portion of the door bumper bar 40 of Example 3 includes: a central flange portion 53, a pair of corner bending portions 52, a pair of wall portions 51, and a pair of outer peripheral flange portions 54, which are the same as those of Example 1. same. In Example 3, the third portion (gradient portion) P43 of the door bumper 40 is formed longer than the third portion P3 of Example 1 in the length direction.

[0084] The corner bending portion 52c of the third portion (gradient portion) P43 includes: a section of a fixed length adjacent to the first portion P41 and maintaining the same cross-sectional area as the first portion P41; and a remaining section adjacent to the second portion P42. In the remaining section, the cross-sectional area of the corner bending portion 52c gradually becomes larger as it approaches the second portion P42.

[0085...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com