Method and device for determining load spectrum for transmission in motor vehicles

A technology for transmissions and motor vehicles, applied to mechanical equipment, registration/indicating vehicle operation, instruments, etc., can solve the problem of complex and expensive assembly of torque sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

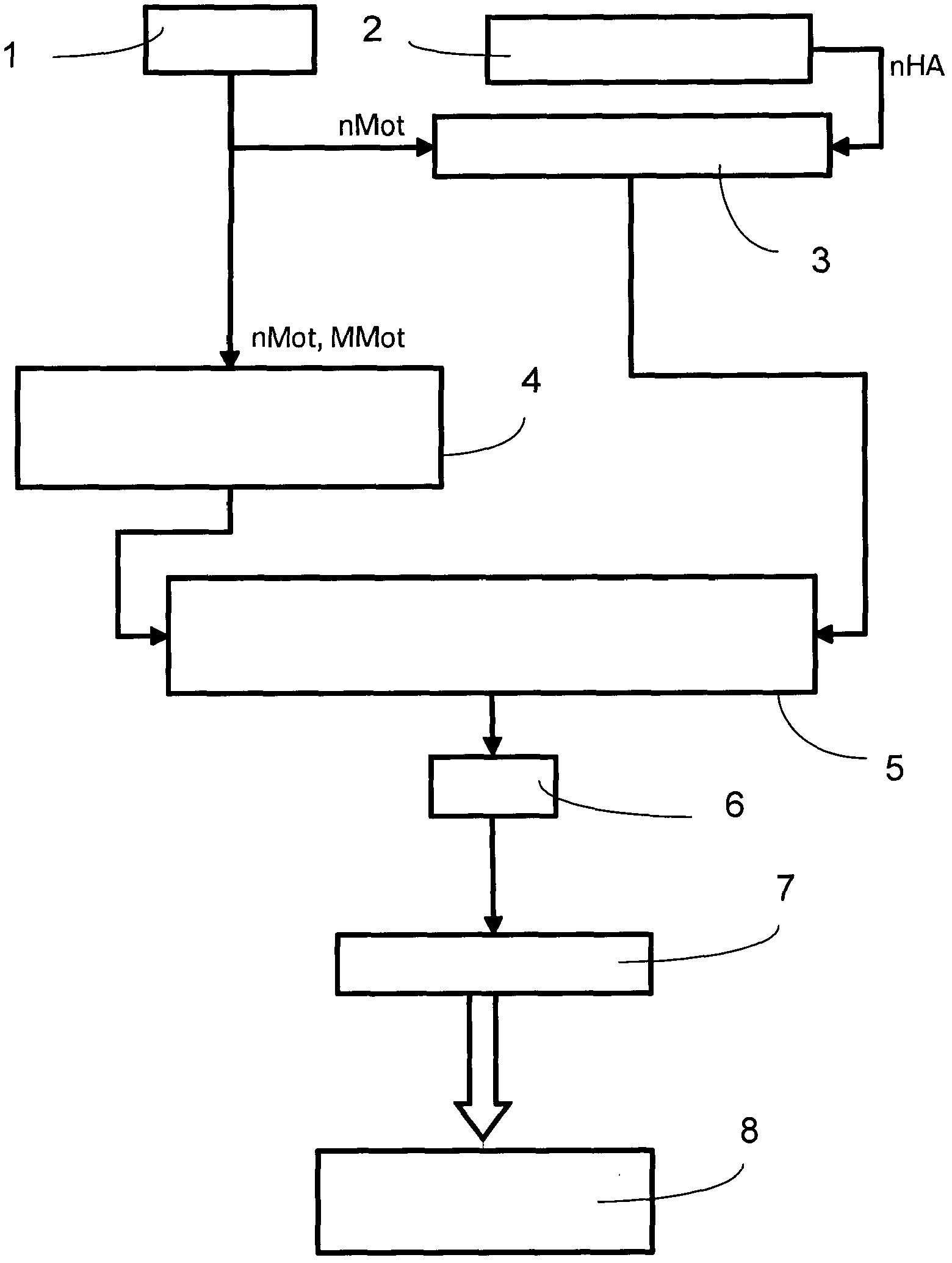

[0029] exist figure 1 , the engine speed nMot and the actual engine torque MMot are collected or determined in the engine operating parameter function box 1. The rotational speed nHA of the drive wheel (here the rear wheel) is determined by a sensor on the drive wheel 2 . The rotational speed nHA of the drive wheels is calculated together with the engine rotational speed nMot in gear determination block 3 to determine the corresponding current gear.

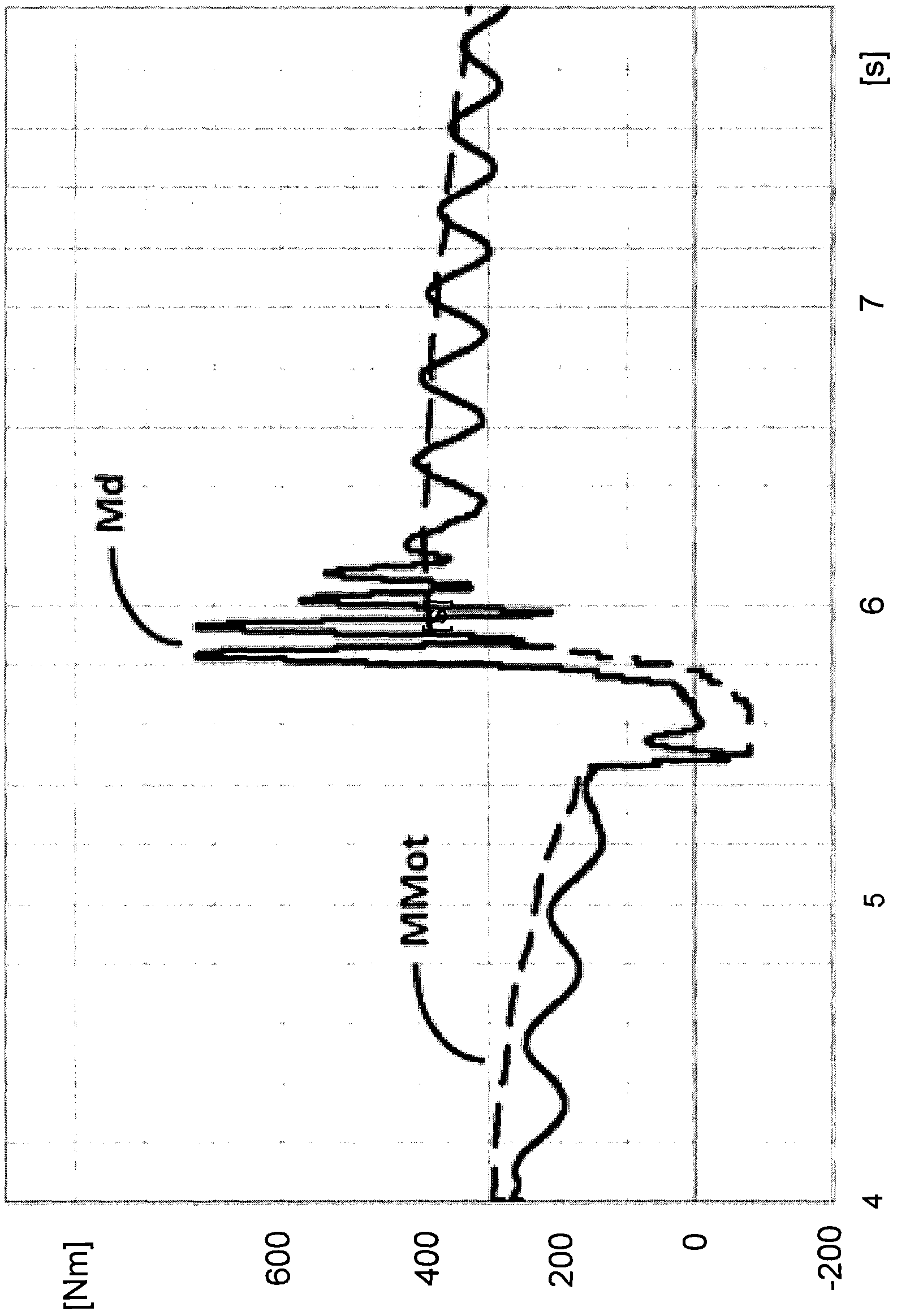

[0030] In a transmission torque determination block 4, a transmission torque Md is calculated from the operating parameters MMot, nMot and other operating parameters discussed in further detail below.

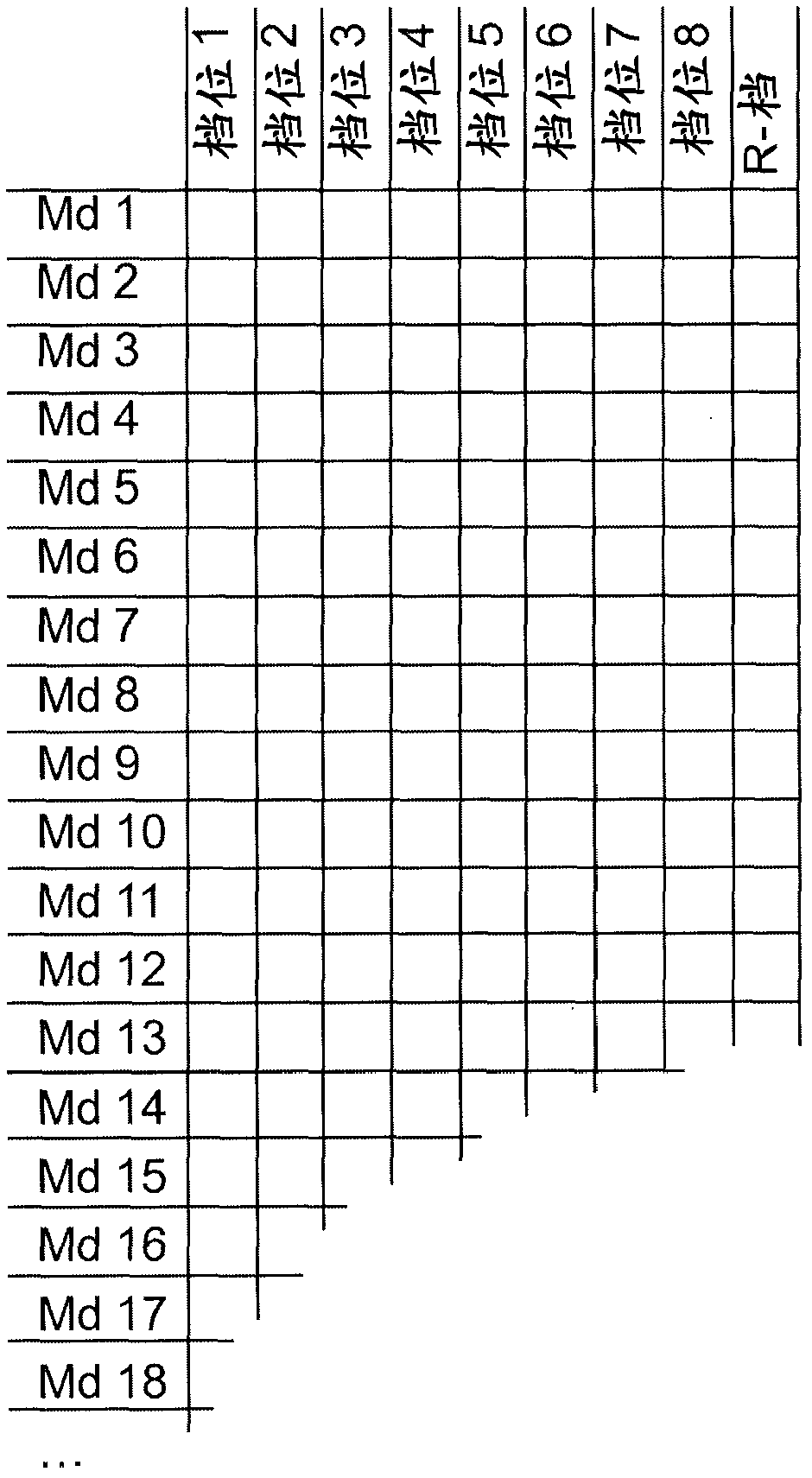

[0031] In the classification block 5, in order to determine the load spectrum, a matrix is generated from the continuously calculated transmission torque values Md in which, for each gear, the transmission torque Md is at a defined transmission torque level (Md i; i= 1, 2, 3 . . . ) are recorded and stored, for example, firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com